Continental to present new electric drive at the IAA

Continental will present the third generation of a fully electric drive train at the IAA. The “first fully integrated axle drive for mass production” weighs less than 80 kilograms and is to be offered in two power ratings of 120 or 150 kW.

Series production of the new axle drive will start in the third quarter of 2019 at Continental’s plant in Tianjin, China – according to the supplier, it is the first “fully integrated axle drive for mass production”. It will be used this year in various electric models from several manufacturers in China and Europe. “Our electric drives are a central component of innovative vehicles – from established manufacturers as well as start-up companies,” says Andreas Wolf, CEO of Continental’s drive business.

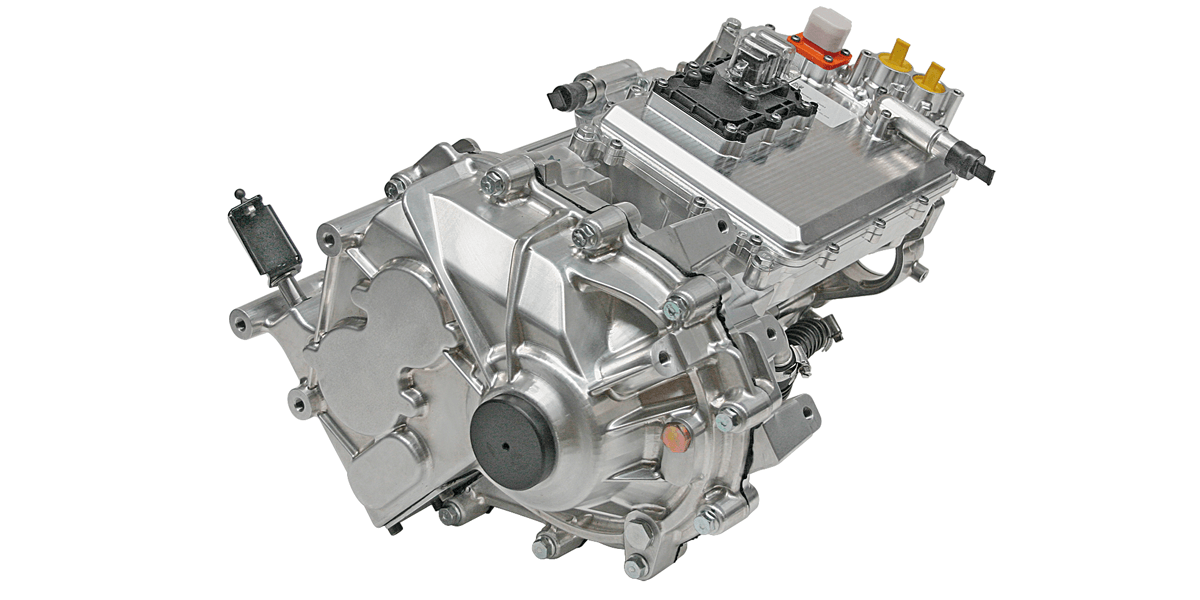

Continental understands the term “highly integrated” to mean that the new high-voltage drive combines electric motor, power electronics and reduction gear in a single housing. The development should also take into account experiences from the everyday use of the first two generations of electric drives, which Conti has been offering since 2011. Among other things, it has been possible to improve installation space and weight.

With the integrated design, the drive was not only smaller and lighter, but also cheaper – simply because numerous cable connections and plugs were no longer required. With an output of up to 150 kW and a maximum torque of 310 Nm, the engine is comparable to a 2-litre turbo diesel engine of conventional design. However, this engine – even with the necessary multi-speed transmission – weighs considerably more than 80 kilograms. In addition, the electric drive can be used in numerous vehicle classes due to its size and characteristics.

Continental cites the Sion from Sono Motors, for example, which is to be built from 2020. This year the engine is to be put on the road “in a European small car and in several compact SUVs from Asian manufacturers”.

0 Comments