Comau se une al proyecto de reciclaje de pilas Reinforce

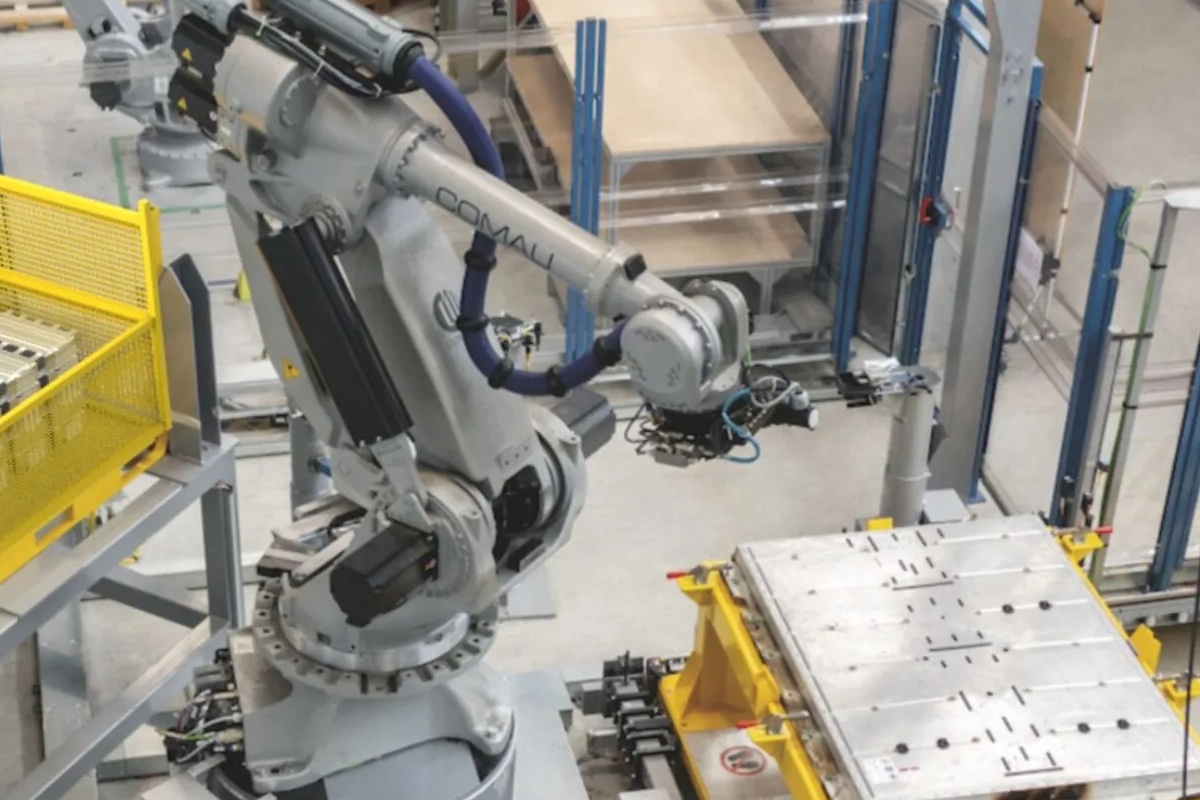

La empresa italiana tiene dos papeles en el proyecto: Por un lado, dirigirá uno de los ocho grupos de trabajo. Por otro, desarrollará una solución de desmontaje versátil y segura para la manipulación de baterías basada en la robótica, el aprendizaje automático y la Industria 4.0.

"Nuestra avanzada solución de desmontaje robotizado no sólo mejorará la eficacia y la seguridad del proceso de desmontaje, sino que también apoyará la economía circular al maximizar la recuperación y la reutilización de los materiales de las baterías al final de su vida útil", explica Andrew Lloyd, Jefe de Ingeniería de Comau.

Al construir una solución integral que gestione eficazmente las baterías de los coches eléctricos y los formatos de baterías estacionarias, el proyecto pretende ayudar a abordar un aspecto crítico del ciclo de vida de los vehículos eléctricos y avanzar en el objetivo general de reducir los residuos y reutilizar materiales valiosos.

El El objetivo del proyecto es crear un sistema estandarizado, automatizado, seguro y rentable que procesa las baterías de iones de litio para su uso secundario y por terceros y su reciclaje. Reinforce se centrará en la optimización de las rutas de recogida y logística, la mejora de las técnicas de diagnóstico y recuperación y la introducción de procesos de desmontaje seguros y eficaces que optimicen la reutilización y permitan al mismo tiempo una trazabilidad completa.

"Este proyecto subraya la creciente necesidad de desarrollar una vía de electrificación circular y representa un importante paso adelante en la gestión sostenible de las baterías", añade Lloyd.

Comau no sólo se dedica al reciclaje, sino también a la producción de baterías para coches eléctricos. Junto con LiNa Energy, del Reino Unido, está desarrollando una solución de fabricación de pilas de sodio en estado sólido. Comau también participa en el proyecto BATTwin de la UE para la producción sostenible de baterías.

0 Comentarios