Cyclic Materials invests $20 mn in its first US recycling facility

According to the company, this is its first facility to focus on the separation of permanent magnets from end-of-life products. These were previously not recovered. It is also its first location in the United States.

The new facility, which is scheduled to open its doors in early 2026, will offer 30 jobs. Recruitment for these positions will start before the end of June.

“We are proud Cyclic Materials will establish its first U.S. facility right here in Arizona,” said Governor Katie Hobbs. “This facility will create family-sustaining jobs and support thriving industries, all while advancing Arizona’s clean energy economy.”

The process used to recover rare earth magnets is called MagCycle, which was developed by Cyclic. The company launched a commercial demo facility using the process in 2023. This was followed last year by a demonstration plant (‘Hub100’) in Kingston, Canada, for the second process step to produce mixed rare earth oxides from the material.

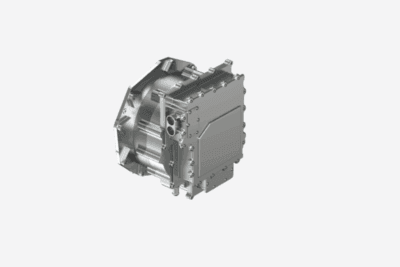

In the case of electric mobility, the rare earth magnets that will be recycled come from old motors, more precisely from the rotor of permanently excited synchronous machines. Permanent magnets, which usually contain rare earths, are installed there. However, Cyclic Materials is not limited to this one source of raw materials: Other material streams for rare earth magnets include wind turbines, MRI devices and electronic scrap, for example, from data centres.

“We have chosen the vibrant Southwest for our first U.S. and global site to be close to feedstock that will support our mission to address the global supply-demand imbalance for rare earth materials,” said Ahmad Ghahreman, CEO and co-founder of Cyclic Materials. “By developing circular supply chains, we can reduce dependence on overseas sources and secure a more stable REE supply for the future.”

Rare earth elements (REE) are among the least recycled metals due to the difficulty of separating the various magnetic materials in end-of-life products. So, since its inception in 2021, Cyclic Materials has been creating recycling processes for REE and other metals like copper, aluminium, steel, cobalt, and nickel from a diverse supply of end-of-life products.

BMW – or, more precisely, the investment company BMW i Ventures – is one of the early shareholders and partners of Cyclic Materials and has been invested since 2023. Since the beginning of the year, the Canadian company can also count Tata subsidiary JLR to its investors. The latter provided 2 million dollars through its investment company InMotion Ventures during the Series B financing round.

0 Comments