IEA analysis: battery demand exceeds one terawatt hour for the first time

“The battery industry has entered a new phase,” says the International Energy Agency (IEA). With electric car sales rising by 25 per cent to 17 million in 2024, annual battery demand exceeded one terawatt hour for the first time last year. The IEA includes all types of batteries in this figure. However, as batteries installed in electric vehicles currently account for 85 per cent of the global battery market, it sees the increase above the TWh mark primarily as a result of the growing EV market.

At the same time, the average price of a battery pack for electric cars has fallen to below 100 US dollars per kilowatt hour in the past year, according to the study authors – “commonly thought of as a key threshold for competing on cost with conventional models,” writes the IEA. Cheaper battery minerals have been an important driver here. “Lithium prices, in particular, have dropped by more than 85% from their peak in 2022.” However, the rapid progress in the battery industry itself has also contributed to the price drop, the analysts add.

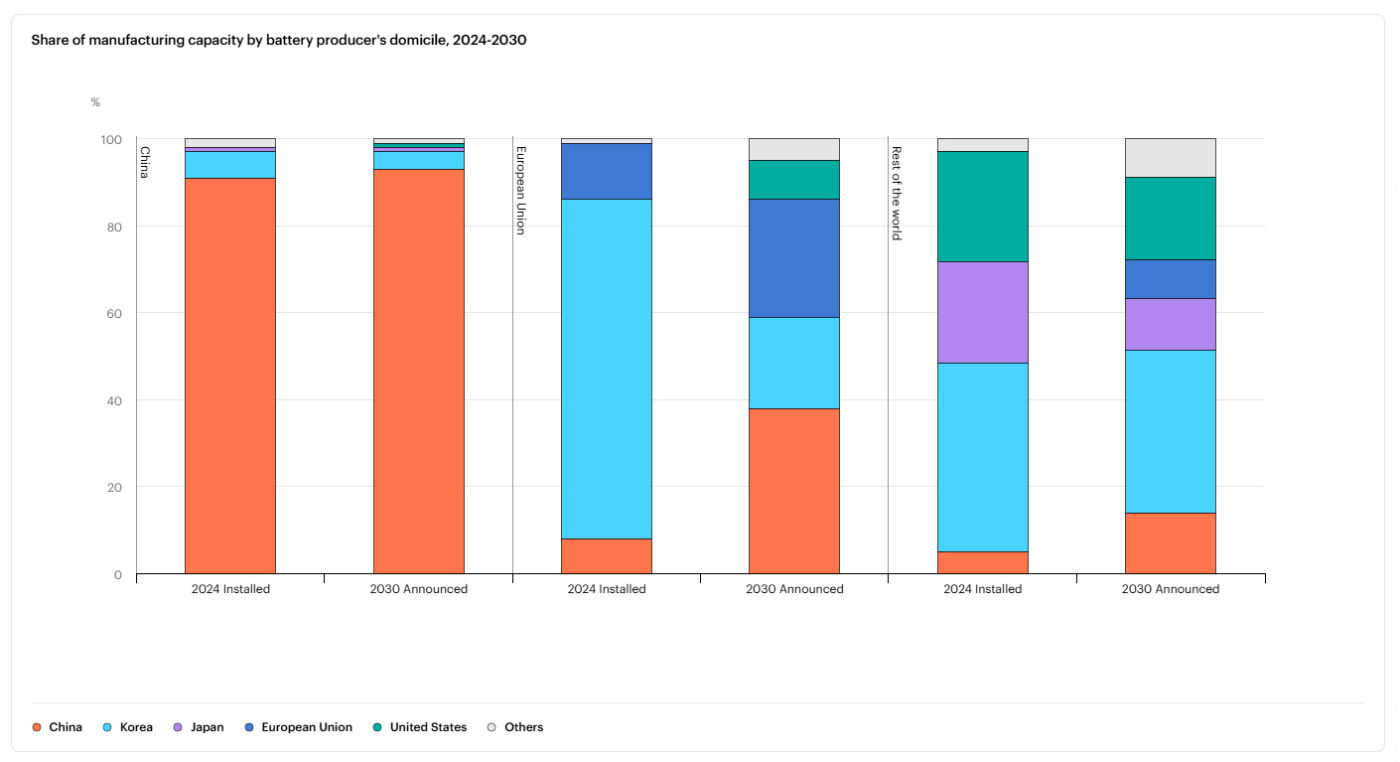

According to the study, global battery production capacity will reach 3 TWh by 2024. It is a theoretical value that manufacturers could achieve if their current production facilities were running at full capacity. According to the IEA’s forecast, this production capacity could triple again in the next five years – “if all announced projects are built.”

In addition to the production volume, the structure of the battery market has also changed: While markets used to be regionalised and small, they are now global and very large, and a range of technological approaches is giving way to standardisation,” the analysts state. “Looking ahead, economies of scale, partnerships along the supply chain, manufacturing efficiency, and the capacity to bring innovations swiftly to market will be crucial to compete.” The IEA experts estimate that it will probably lead to greater consolidation throughout the industry. At the same time, the industry will be reshaped by government-driven efforts to geographically diversify battery supply chains.

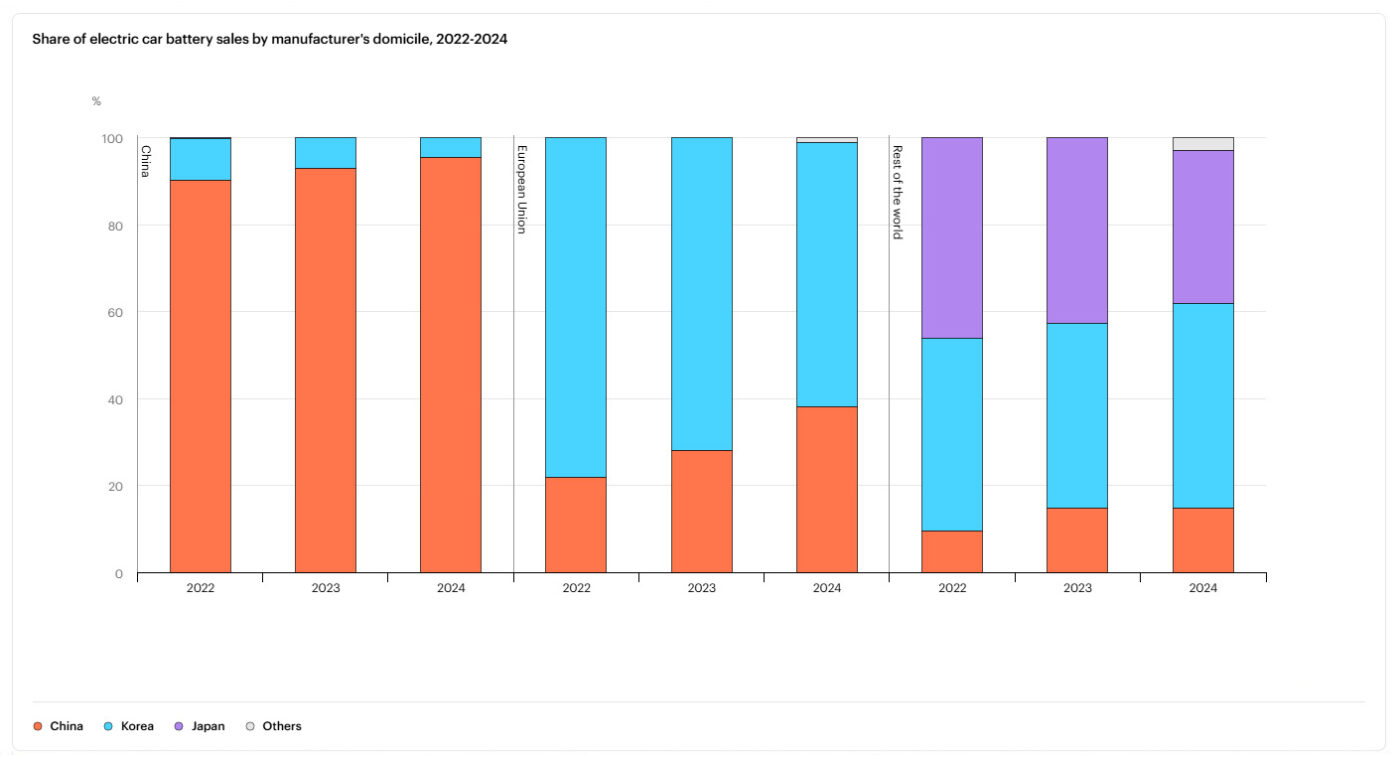

The dominant player in the battery market is and remains China: more than three-quarters of the batteries sold worldwide in 2024 were manufactured in China, and nowhere else did average prices fall faster than there last year, namely “by nearly 30%.” According to the IEA, batteries are over 30 per cent and 20 per cent cheaper in China than in Europe and North America, respectively. According to the study, the price advantage of Chinese manufacturers can be attributed to four main factors:

- China has extensive manufacturing expertise, as more than 70% of all electric car batteries ever made were produced in China.

- The supply chain integration is a result of acquisitions by a few companies. The Chinese battery ecosystem ranges from mineral mining and refining to the final production of batteries and electric vehicles.

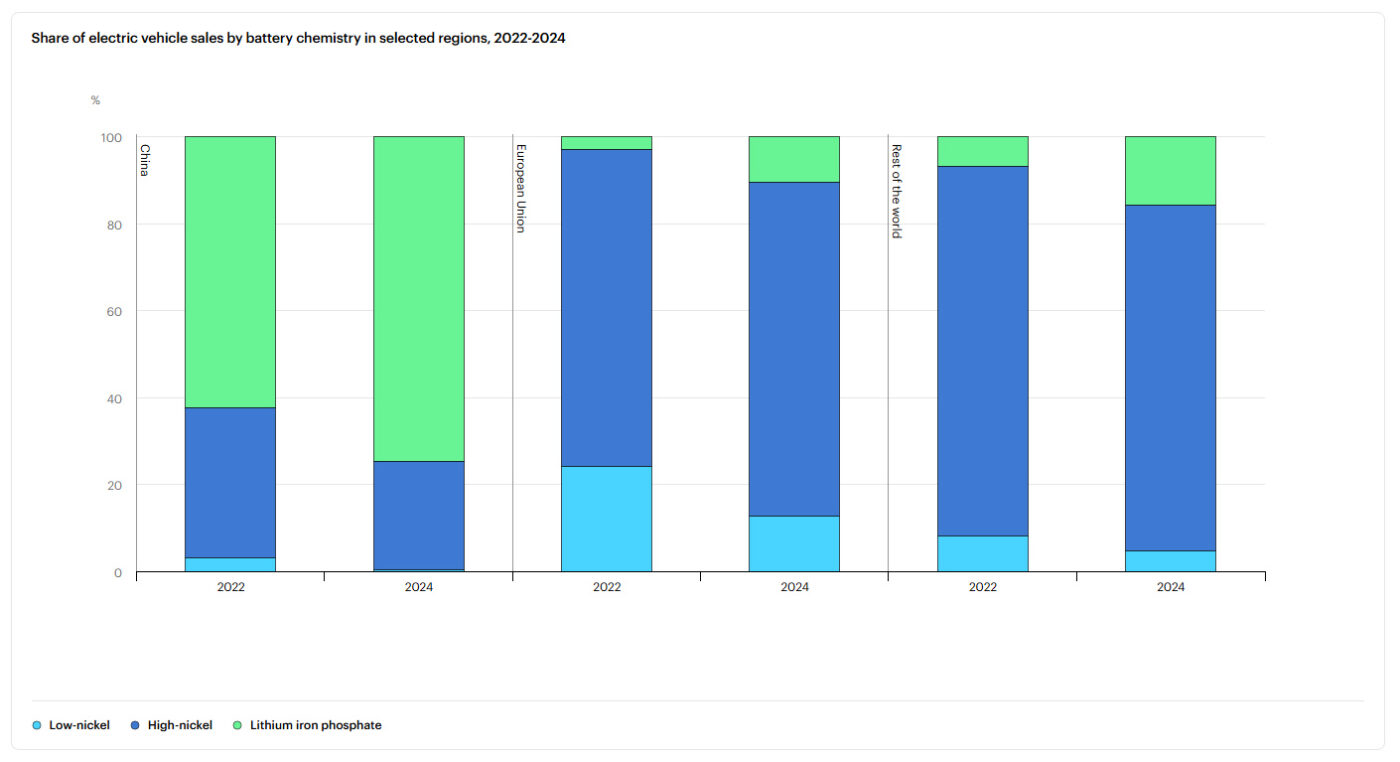

- Chinese manufacturers have prioritised cheaper lithium iron phosphate (LFP) chemistry. Initially, it was considered unsuitable for electric cars due to its lower energy density. Thanks to years of research and development by Chinese manufacturers, LFP batteries now account for almost half of the global market for electric cars, having more than tripled their share within five years. According to the IEA, they are now around 30 per cent cheaper than nickel-cobalt-manganese (NMC) batteries.

- The Chinese battery market, where nearly 100 manufacturers are active, is characterised by fierce domestic competition. To maintain or gain market share, these companies have reduced their profit margins to sell batteries at lower prices.

However, the International Energy Agency assumes that the fall in prices in China will slow down in the near future. That is because consolidation is likely to give some manufacturers “greater influence and pricing power.” Elsewhere, however, the competitive advantage of the Chinese electric car and battery industry poses a major challenge. “Many battery producers in Europe are postponing or cancelling expansion plans because of uncertainty about future profitability,” says the IEA. Production costs in the region are around 50 per cent higher than in China, the battery supply chain ecosystem is still relatively weak and there is a shortage of skilled workers. “The bankruptcy of Northvolt – Europe’s largest investment in a homegrown battery maker – underscores the difficulties of competing with Asian producers,” the authors conclude.

However, Europe can catch up, according to the IEA’s positive message. If domestic demand grows reliably and manufacturers are given time to optimise their production processes and develop strong regional industrial ecosystems. “On this front, clear policy that signals continued demand growth and reduces investment risks is essential,” emphasises the International Energy Agency.

According to the analysts, it is already measurable that Europe is stepping up efforts to produce cheaper LFP batteries in the region. Korean manufacturers – traditionally the largest battery producers in Europe – have lost almost a quarter of their market share in the European Union over the past two years (from almost 80% in 2022 to 60% in 2024), which the IEA attributes in part to the increasing success of LFP batteries produced in China. Some Korean companies have now also started to invest in the production of LFP batteries in Europe. However, China is continuing to exert pressure: “Projects such as the joint venture between Stellantis and CATL could speed up the uptake of LFP batteries in the region, improve Europe’s battery ecosystem and potentially reduce the cost gap with China.”

For 2030, the IEA forecasts a market share of 38 per cent for the European Union battery market in the hands of Chinese companies, only 21 per cent Korean manufacturers, 27 per cent own production from the EU, 9 per cent US companies and 5 per cent from other manufacturers.

Korea and Japan are thus facing major upheavals. They are currently home to major battery manufacturers and specialised suppliers with extensive expertise in the field of NMC batteries – and have a particularly strong international presence: “Korean companies lead in overseas manufacturing capacity, with nearly 400 gigawatt-hours (GWh), far surpassing Japan’s 60 GWh and China’s 30 GWh,” states the IEA. The IEA experts estimate that this will probably lead to greater consolidation throughout the industry. At the same time, the industry will be reshaped by government-driven efforts to geographically diversify battery supply chains.

In the United States, battery production capacity has doubled since 2022 following the introduction of tax credits for manufacturers and will reach over 200 GWh in 2024. According to the IEA, almost 700 GWh of additional production capacity is under construction. However, according to the study, the development of domestic capacity for the production of battery components has progressed more slowly, “so most anode and cathode demand is still satisfied by imports.” In the meantime, Southeast Asia and Morocco have emerged as potential production locations for batteries and their components.

Graphic 1: IEA (2025), Share of electric vehicle sales by battery chemistry in selected regions, 2022-2024, IEA, Paris https://www.iea.org/data-and-statistics/charts/share-of-electric-vehicle-sales-by-battery-chemistry-in-selected-regions-2022-2024, Licence: CC BY 4.0

Graphic 2: IEA (2025), Share of electric car battery sales by manufacturer’s domicile, 2022-2024, IEA, Paris https://www.iea.org/data-and-statistics/charts/share-of-electric-car-battery-sales-by-manufacturer-s-domicile-2022-2024, Licence: CC BY 4.0

Graphic 3: IEA (2025), Share of manufacturing capacity by battery producer’s domicile, 2024-2030, IEA, Paris https://www.iea.org/data-and-statistics/charts/share-of-manufacturing-capacity-by-battery-producer-s-domicile-2024-2030, Licence: CC BY 4.0

0 Comments