Fraunhofer study measures China’s dominance in the battery supply chain

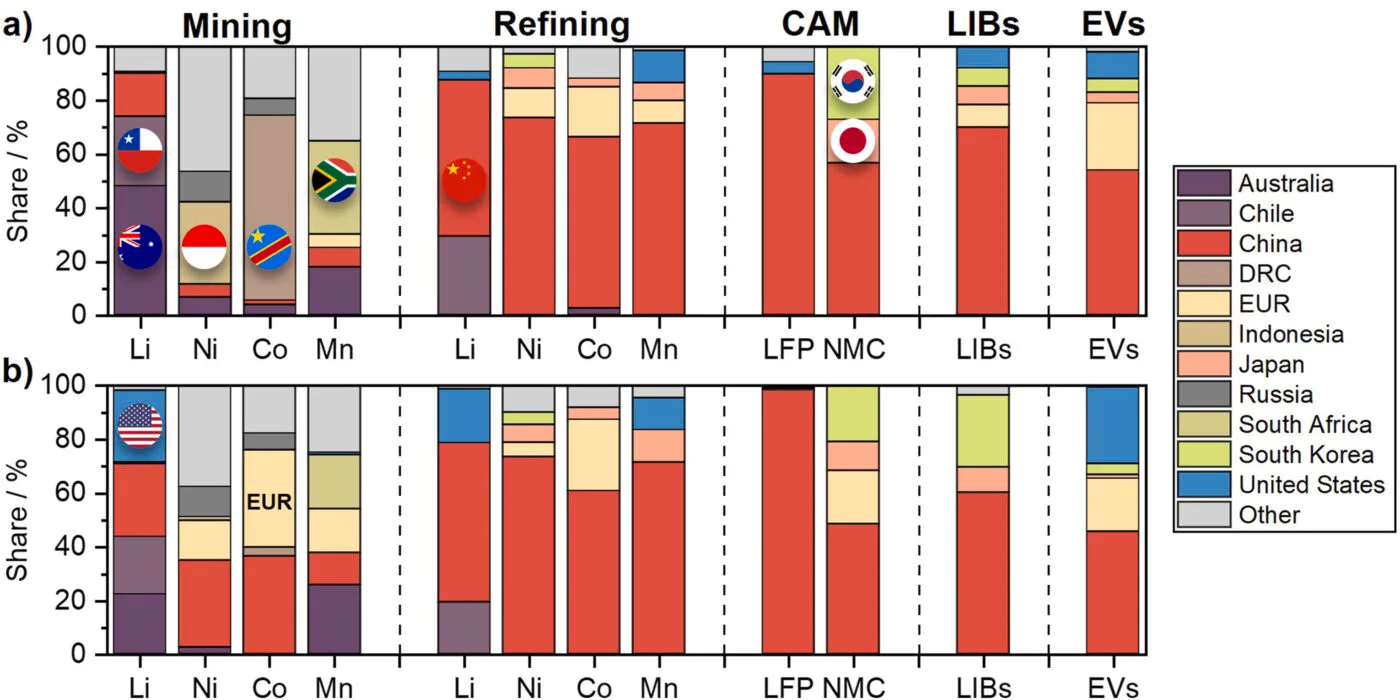

The analysts conclude that the People’s Republic of China controls almost the entire value chain from the extraction of raw materials to the production of batteries – and controls domestic production facilities, as well as those abroad. Of the four raw materials analysed – lithium, nickel, cobalt and manganese – only manganese is an exception. The refinement of the raw materials and the construction of the actual cells and batteries is also dominated by China, as the latest annual analysis by SNE Research shows. The leading duo CATL and BYD alone account for 55 per cent of the global market share for installed battery capacity in electric cars.

As the Fraunhofer FFB explains, large battery packs, such as those installed in a Tesla Model S Plaid, contain around 122 kilograms of so-called mineral raw materials. Geographically, only a few countries have the resources needed in large quantities for the expansion of electric mobility. These include China, Australia and the Democratic Republic of the Congo. The challenge: “Mineral raw materials are at the very beginning of the supply chain for battery cell production, and Europe is almost 100 per cent dependent on imports,” says Professor Simon Lux, Director of Fraunhofer FFB.

Securing raw materials in Europe and the USA: between catching up and dependency

In Lux’s view, China’s growing dominance of raw materials jeopardises the future of European electric mobility: “This dependency makes Europe vulnerable. Geopolitical tensions or export stops could lead to massive economic damage and losses running into billions.” Although Europe and the US are intensifying their efforts to gain greater control over the supply chain for lithium-ion batteries by acquiring mines and refineries, Europe’s share has so far been comparatively small. The US is making better progress – at least as far as lithium is concerned.

According to the authors of the study, Australia, Indonesia and the Democratic Republic of the Congo – all key regions for mining lithium, nickel and cobalt – are particularly affected by company takeovers. For example, 74 per cent of the world’s lithium comes from Australia and Chile, but Chinese (29 per cent) and US companies (26 per cent) hold the largest shares of production. “These developments underline the global competition for critical raw materials and the strategic realignment of value chains,” says Lux.

For the four raw materials analysed – lithium, nickel, cobalt and manganese – the study outlines the following picture of global ownership and influence:

- Lithium: 74 per cent of the world’s lithium comes from Australia and Chile. Nevertheless, companies such as Tianqi Lithium from China and Albemarle from the USA hold the largest shares of global production, with China accounting for 29 per cent and the US for 26 per cent. Europe has almost no lithium shares abroad. Europe’s own shares are negligible and have so far been limited to the Baroso lithium project in Portugal, which accounts for just 0.4 per cent of production.

- Nickel: Although 30 per cent of global nickel production takes place in Indonesia, Indonesian companies account for less than five per cent of production. Chinese companies, such as Tsingshan, secure 86 per cent of the remaining production in Indonesia, meaning China has the greatest control (32 per cent) over nickel production in combination with domestic production. The most influential regions after China include Europe, the Philippines and Russia, which together account for just over 40 per cent of global production.

- Cobalt: Local companies control only five per cent of the mines, although 68 per cent of global production takes place in the DR Congo. China (47 per cent) and Europe (47 per cent) dominate production there – with players such as CMOC, Glencore and Eurasian Resources Group (ERG). Outside Chinese and European control, the Philippines, Russia and Cuba are influential (12 per cent).

- Manganese: Australia is expanding its influence to a total of 25 per cent by acquiring more than half of South African mining rights through the companies South 32 and Jupiter Mines. South Africa is in second place with 20 per cent, followed by Europe, which has a total share of 16 per cent of global manganese production. These shares are spread across mines in Australia, Gabon and Ukraine, which were acquired by Anglo American, Eramet and ERG.

The analysts note that China has a particularly large lead in the LFP battery sector. Accordingly, China produces the majority of lithium iron phosphate active materials with a share of more than 98 per cent. The conclusion is that this means Europe is directly dependent on this more cost-effective battery chemistry. So, what can be done from a European perspective? According to the authors, possible levers for a secure and sovereign battery supply chain in Europe could be investments in expanding Europe’s own refinery capacities, promoting strategic raw material partnerships and strengthening the local circular economy.

In terms of methodology, the researchers from Fraunhofer FFB and the University of Münster state that the study is based on a comprehensive data analysis. To this end, the ownership structures along the global lithium-ion battery supply chain were analysed and compared with the geographical distribution of production shares. The study’s initiators aimed to “draw a holistic picture of the current power structures in the industry.”

0 Comments