Research project launches for 2nd-life use of lithium-ion batteries

As part of the research project funded by the Federal Ministry of Education and Research (BMBF), in which the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, the Friedrich-Alexander University Erlangen-Nuremberg and the company Industrial Dynamics are involved, an interdisciplinary project team has tackled questions such as: Is it possible to reuse used batteries from electric vehicles efficiently and safely? Or: What technical and economic hurdles need to be overcome? Building on this, ‘QuaLiProM’ has set itself the scientific goal of determining the residual capacity and service life of used lithium-ion batteries in a non-destructive, fast and safe manner, so that a reliable and economically viable second use is possible.

Lithium-ion batteries lose storage capacity over the years and their performance decreases accordingly over time. The state of health of a battery is usually defined by the state of health (SoH), which describes the age-related change in the state of a cell in relation to its original state. Determining the SoH is a key factor in assessing the performance and service life of batteries.

To date, experimental methods such as capacity tests, electrochemical impedance spectroscopy or lifetime tests have been used to determine the SoH of batteries, whereas the ‘QuaLiProM’ project uses quantum magnetometry. This method, which is already used in battery research, enables the health status of battery cells to be determined quickly, cost-effectively and precisely. With the help of this method, the condition-dependent magnetisation of a battery cell can be precisely determined. Defects, impurities and the state of charge can be detected using quantum sensors.

The ‘QuaLiProM’ project is now combining quantum magnetometry and artificial intelligence to develop a high-speed measurement method that will make it possible to classify cells based on their state of health in industrial applications. To develop this rapid test methodology, lithium-ion cells are subjected to forced degradation using cyclic ageing tests.

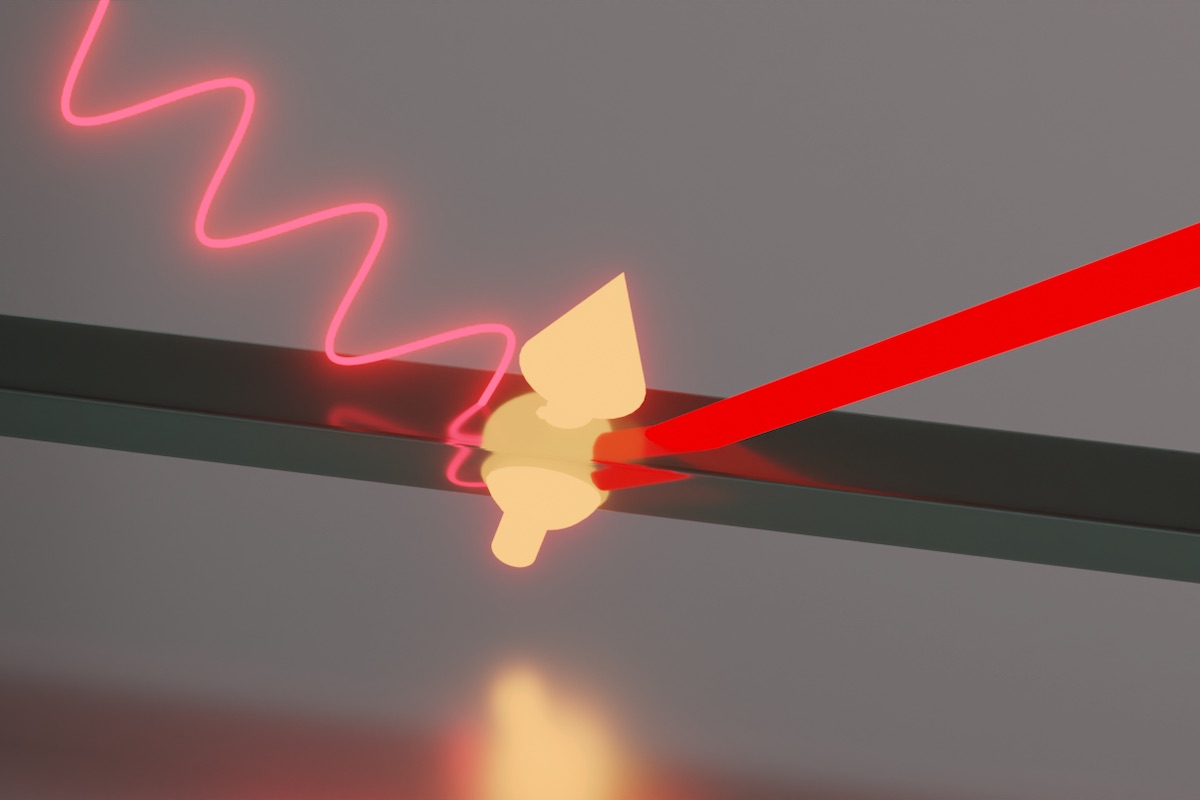

The battery cells that have been transferred to defined ageing states using the ageing tests are then analysed using quantum magnetics. The quantum sensor measures the magnetic field of the cells with high precision by observing the spin of a special defect in a diamond, which emits different numbers of light particles depending on the magnetic field. In this way, magnetic field mappings are generated that provide valuable information about possible anomalies in the battery cells.

This non-destructive method does not require time-consuming charging and discharging cycles and is therefore suitable for use in cell production as well as in the recycling or upcycling process. The upcoming transfer of the methodology from the laboratory level to the industrial scale is one of the main objectives of the project.

For the AI-based analysis of the magnetic field mappings, innovative deep learning methods are used to identify characteristic features, which show a clear correlation to the ageing state of the cells. These features are used to classify cells according to their state of health, categorizing them as either healthy, degraded or defective. In this way, degraded but still functional cells that are no longer suitable for use in electric vehicles due to insufficient capacity can be identified. By developing suitable upcycling strategies and researching new second-life applications in less demanding areas, the project aims to promote the sustainable and resource-efficient use of battery cells and accelerate their transfer to industry.

1 Comment