BMW announces recycling partnership with SK tes

Following the successful establishment of a closed loop for the reuse of raw materials from high-voltage batteries by BMW Brilliance Automotive Joint Venture (BBA) in China in 2022, the BMW Group has now launched a Europe-wide partnership with SK Tes, a provider of technology life cycle solutions.

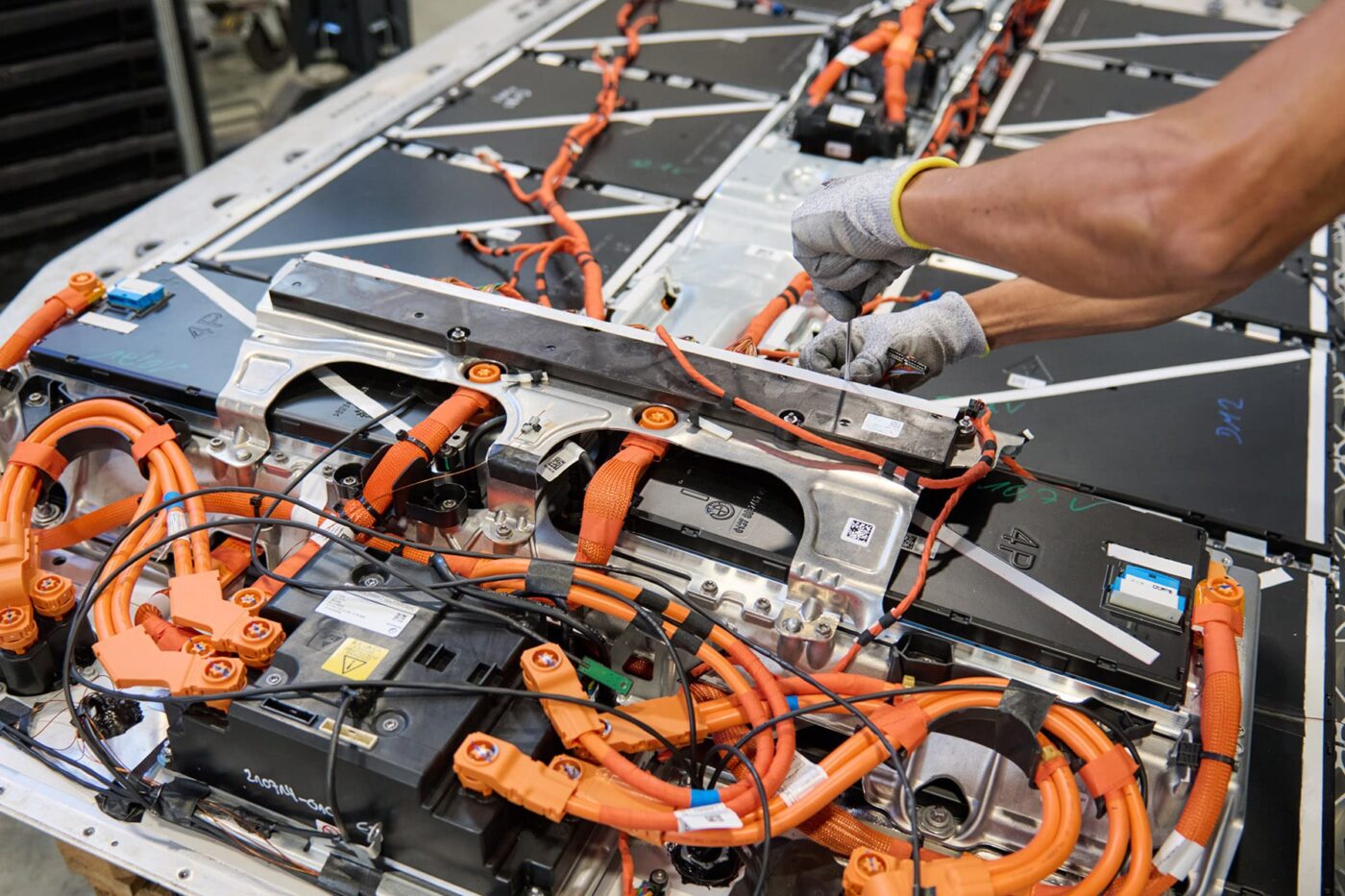

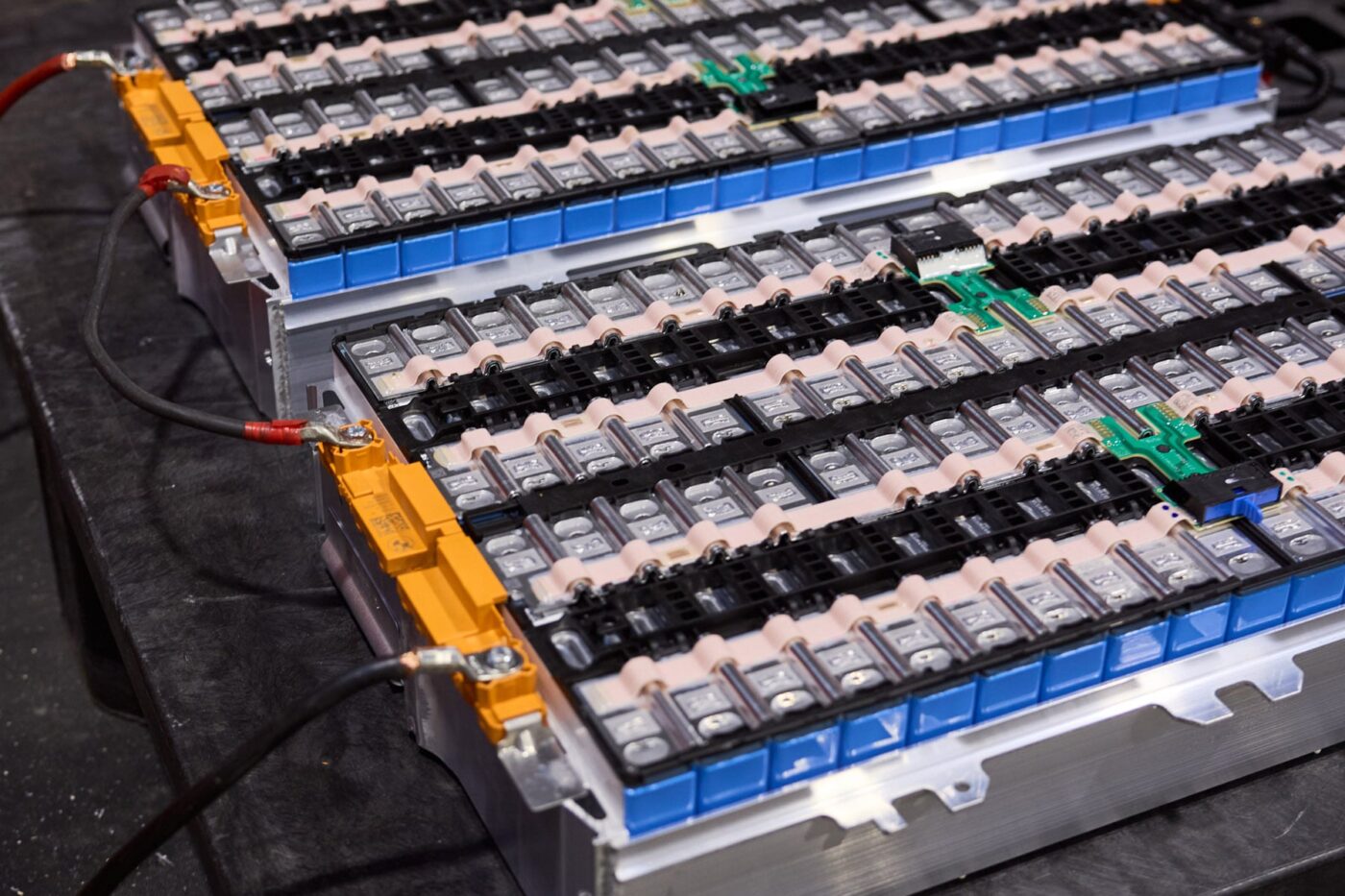

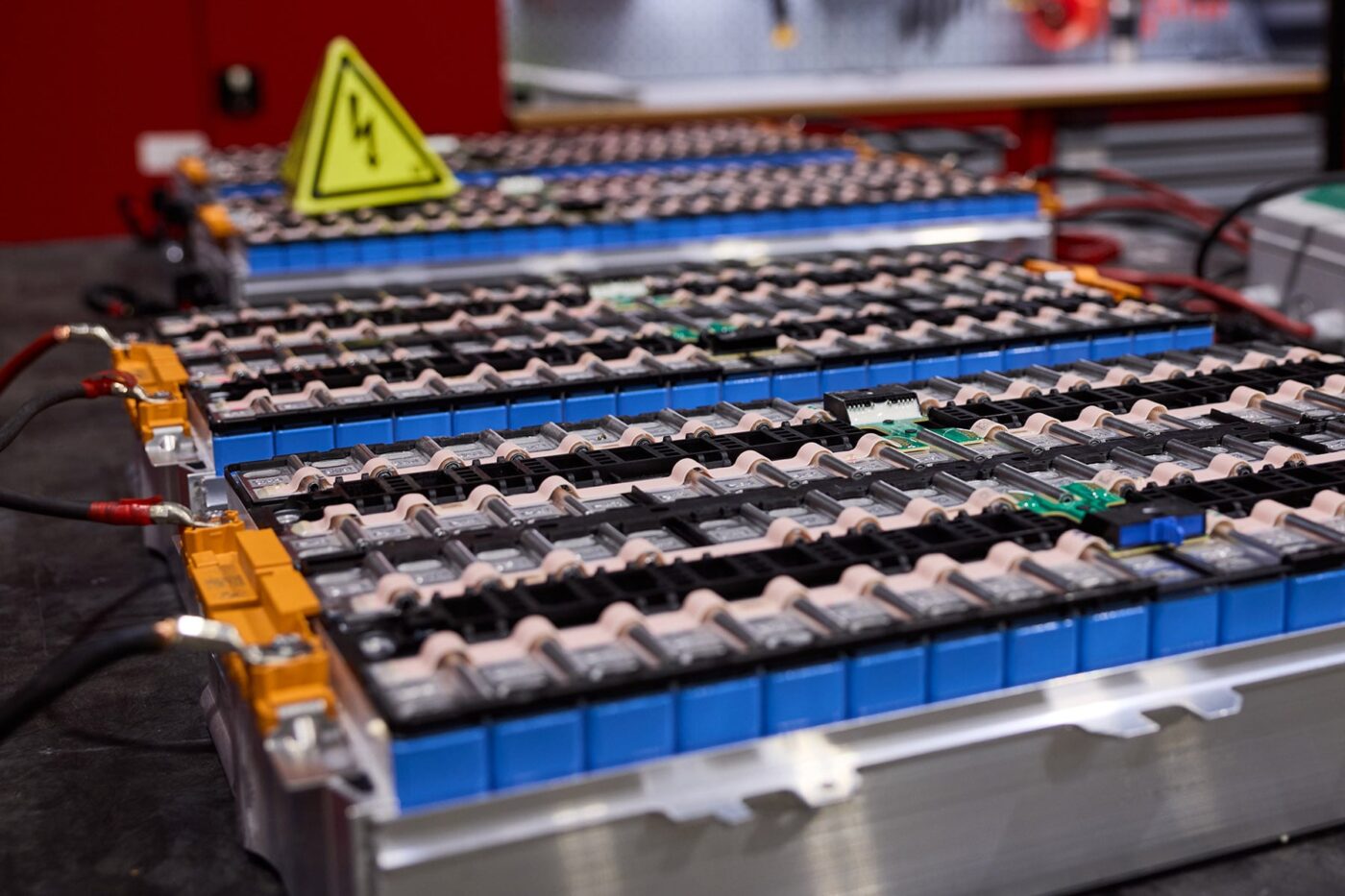

In a special recycling process, cobalt, nickel and lithium are extracted from used batteries and then returned to the value chain for the production of new batteries. This closed cycle is to be expanded across the USA-Mexico-Canada region in 2026. The process will involve mechanically shredding the old batteries, during which the metals are concentrated to leave a material called ‘black mass.’ The materials, specifically nickel, lithium and cobalt, are then recovered in a hydrometallurgical process. “Among other things, these secondary raw materials will be used for the new GEN 6 drive train,” BMW writes.

“Partnerships like this increase our efficiency in terms of the circular economy. In the closed-loop process, all partners mutually benefit from their experiences,” says Jörg Lederbauer, Vice President of Circular Economy, Spare Parts Supply High Voltage Battery and Electric Powertrain at BMW AG.

“The development of recyclable products, the increase of secondary materials in our components, and the closing of loops play an equally important role,” added Nadine Philipp, Vice President of the Sustainability Supplier Network at BMW AG. “And by the means of circular economy, we are also increasing our resilience in the supply chains.”

SK tes currently operates and owns over 40 facilities, employing around 2,600 specialists in over 40 countries. The company boasts of a recovery rate of over 97% for battery materials, and even counted how many kg of assets it has recovered since 2021 with 108,816,085 kg. SK tes was initially founded in 2005. BMW’s press release also covers just how innovative SK tes has been in its approach: “The battery recycling process of SK tes has won numerous sustainability and innovation awards worldwide – from the Business Intelligence Group’s Sustainability Service of the Year to the UN Global Compact’s Apex Award.”

0 Comments