BMW opens new aeroacoustic and electric drive centre

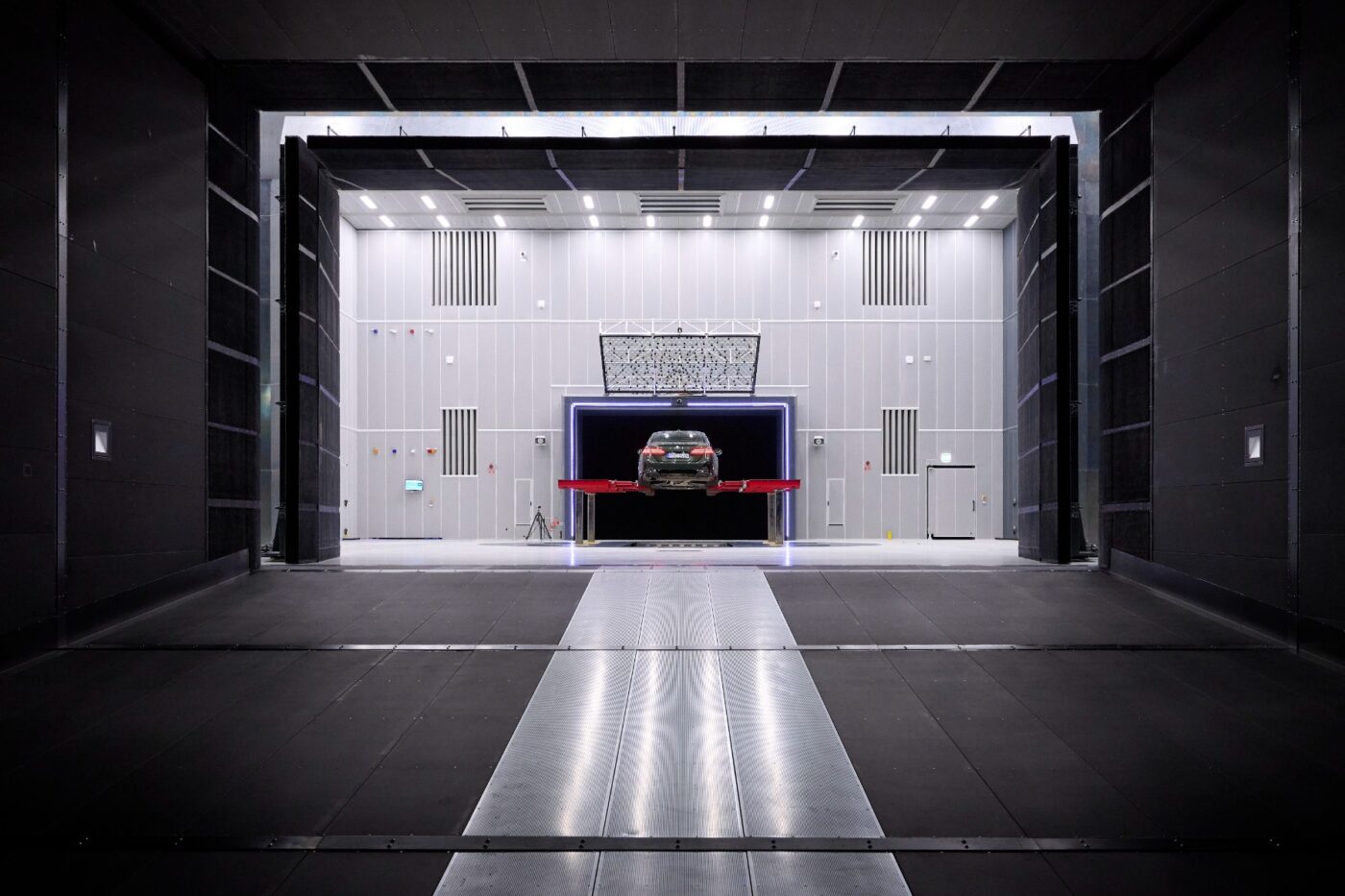

On top of being 100 metres long, it is 25 metres wide and 45 metres high. The background noise level is said to be 54.3 dB (A) at 140 kph, “which is as low as a quiet conversation or a quiet air conditioning system,” BMW emphasises. The blower has a capacity of 4.5 MW, producing winds of up to 100,000 m3 of air per minute and speeds of up to 250 kph. Because of the wind tunnel’s size, it can be used to examine “even the largest and most powerful vehicles such as the Rolls-Royce Phantom or the BMW X7,” says the carmaker.

The new wind tunnel is said to enable “groundbreaking advances in aeroacoustics research.” The goal is to measure the noises caused by headwinds – and to make cars as quiet as possible, particularly the Neue Klasse. “Quiet is premium,” says Daniel Böttger, Head of Complete Vehicle Development at BMW AG. “Our focus is on meeting the premium standards of our vehicles. An important part of this is acoustics — particularly for quiet electric models.”

And the wind tunnel has another feature that will help researchers test aeroacoustics: it is designed as “an acoustic semi-free-field space.” That means the wind tunnel has a sound-resistant floor – but apart from that, there are no sound-reflections. Which is important, because it “enables a realistic simulation of the situation on the road,” says BMW and adds: “The frequency range for semi-free-field conditions from 30 Hz is unique for a vehicle wind tunnel and covers the entire audible spectrum.”

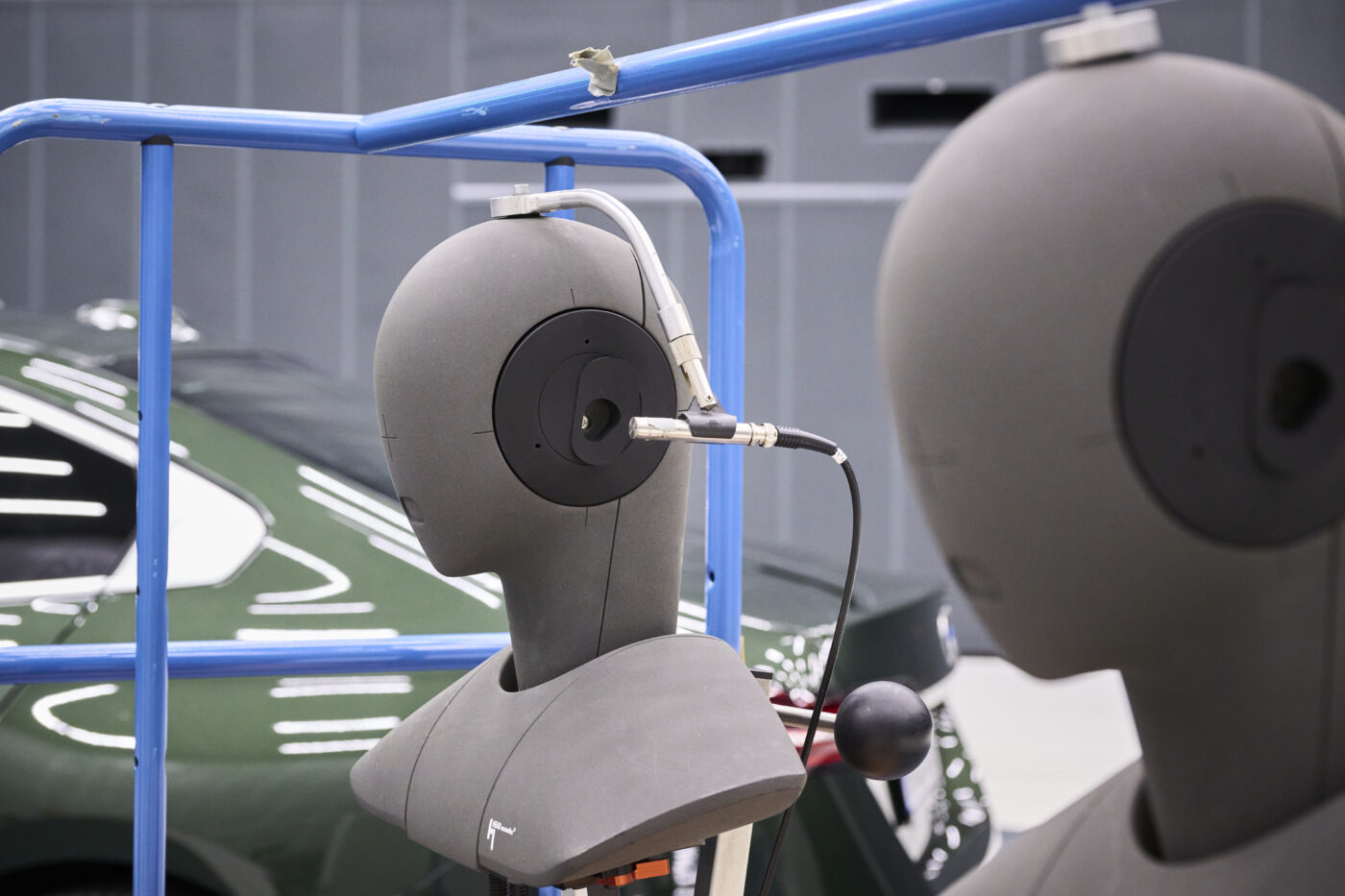

Other features include a 216-microphone acoustic camera to localise background noises “with an accuracy of less than one centimetre” and a laser vibrometry system to measure mechanical vibrations. The tunnel can also “study wind and rolling noises,” separating the phenomena. “In addition, various modules, such as a vehicle-accessible glass floor or a vehicle scale for motorcycles, can be replaced in a short time without moving the vehicle. This allows developers to test different configurations quickly and efficiently,” BMW explains.

On top of the wind tunnel, the AEC is home to 15,000 square metres for building and testing prototypes of electric vehicles. The Group will add another 800 m2 for a pilot line that manufactures inverters for future electric motors.

0 Comments