Toshiba introduces new battery recycling process

In response to the EU Battery Regulation, which went into effect in August 2023, and requires manufacturers to declare carbon footprints and high levels of environmental consideration throughout the product life cycle, necessitating a swift response from companies across the globe.

As the company writes in its press release, Toshiba “developed a direct recycling method that enables the recycling of high-power, long-life oxide anode lithium-ion batteries through a simple heat treatment process, and has demonstrated the effectiveness of this method.”

Toshiba further specifies that the new recycling method leverages characteristics of oxide active materials with stable crystal structures, and utilizes direct recycling, which recycles active materials as they are and without reverting them to their base chemical elements.

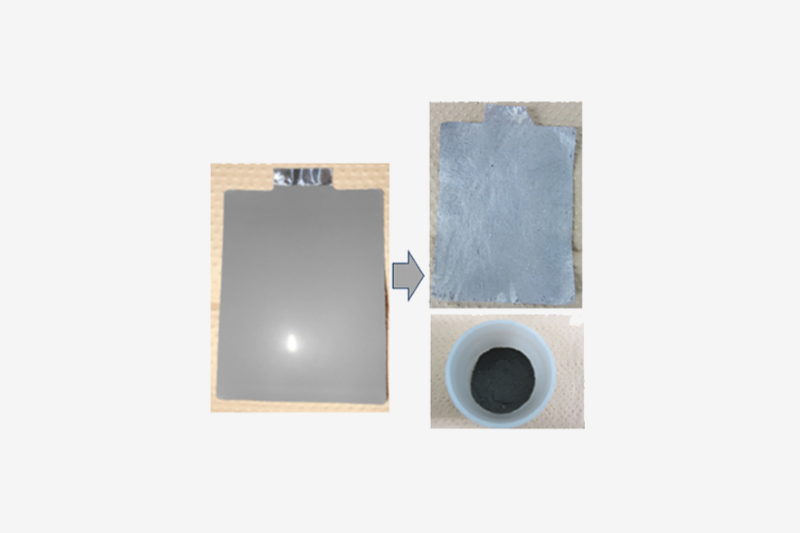

Using the stability of the active material structure, the recycling method enables the active material to be separated from the current collecting foil of the negative electrode in that state by performing a simple heat treatment. Because the structure of the active material is stable, there is no need for complex reactivation processes, thereby enabling the reuse of active materials at a low cost.

Toshiba has also managed to apply this method to its niobium-titanium oxide anode batteries developed by the company. Resulting performance evaluations of the batteries made with recycled electrodes then showed that the electrodes maintain more than 97% of capacity, making their production comparable to new electrodes. According to Toshiba, the recycled batteries themselves also showed the same long life as the new batteries.

This is Toshiba’s first major foray into battery recycling, but the company is actively involved in several areas of battery production, as well as recently entering into the battery swapping game. A design cooperation for hydrogen aircraft was also announced with Airbus in October

0 Comments