Honda opens pilot production line for solid-state batteries

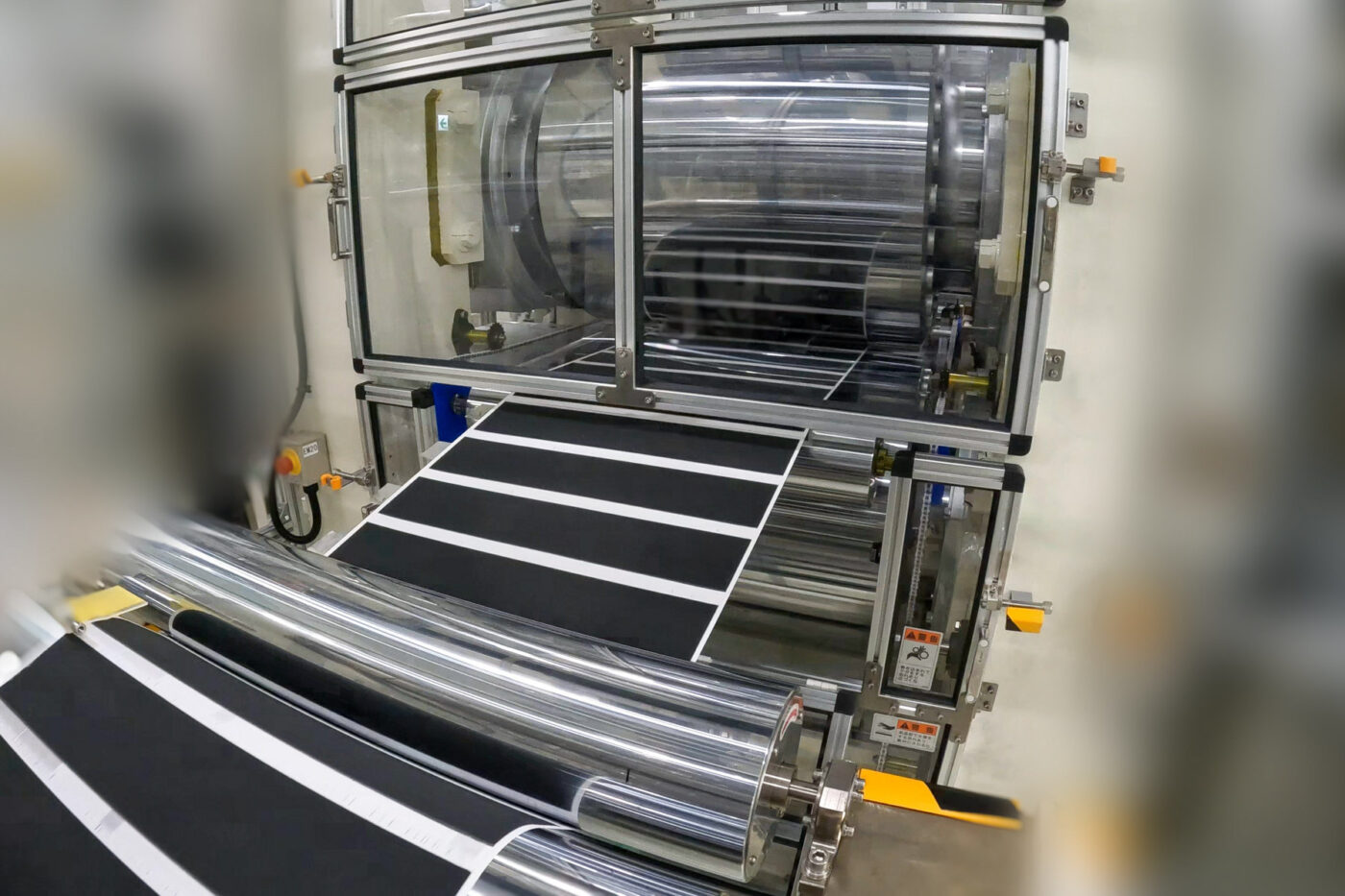

The Japanese company is sticking to its schedule of launching its own solid-state battery cells on the market in the second half of this decade. The new plant in Sakura will help reach that goal. The demonstration line “replicates processes required for the mass production”, Honda says. “The demonstration line has a total floor area of approximately 27,400 m2 (295,000 ft2), and is equipped with facilities and equipment that enable verification of each production process, including weighing and mixing of electrode materials, coating and roll pressing of electrode assembly and the formation of cells, and assembly of the module.”

Construction of the building was completed in the spring when the production machines and measuring instruments were installed and checked. The company plans to start battery production on the pilot line in January 2025.

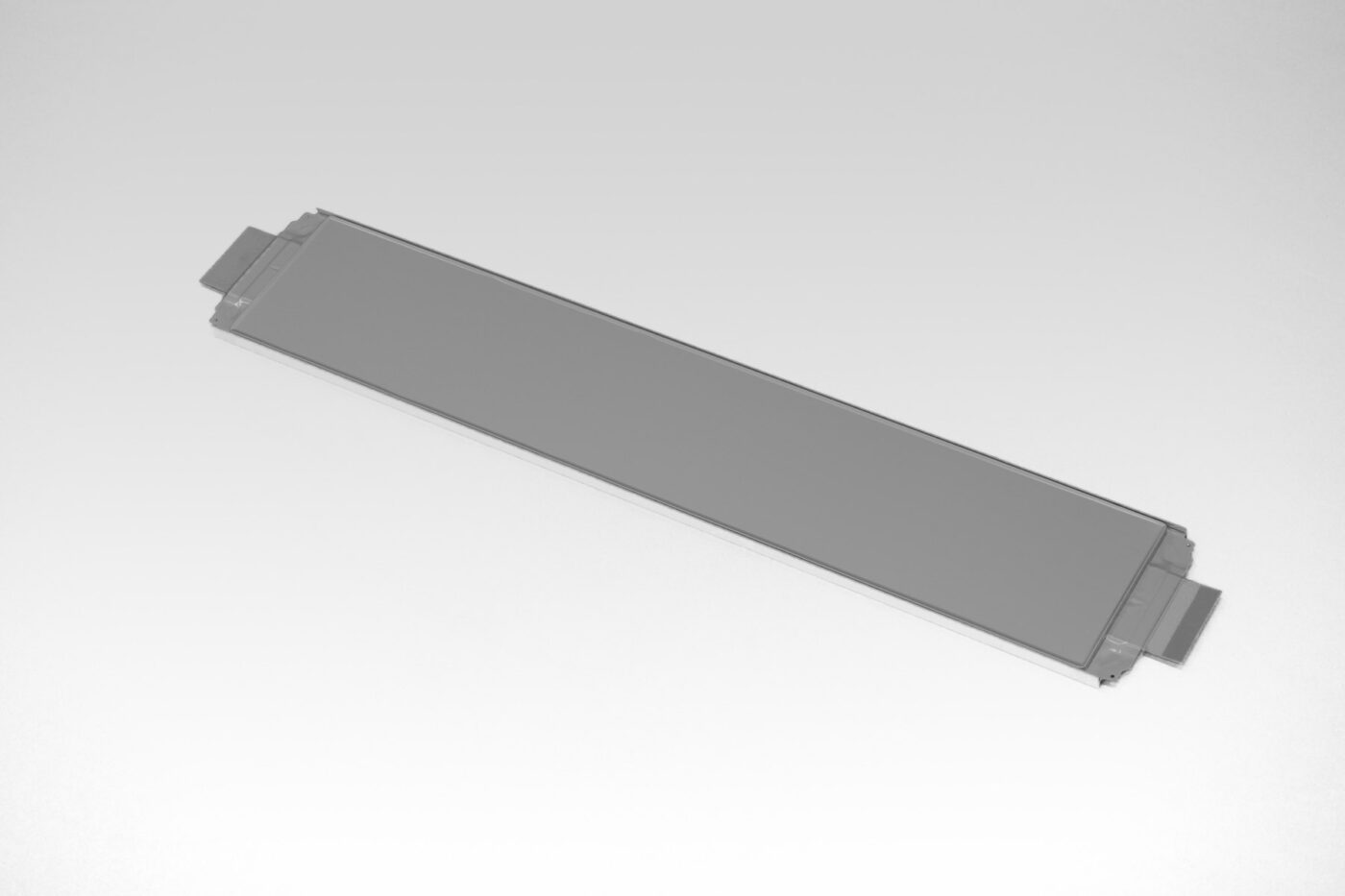

The aim is not only to refine the production processes but also to determine the final specifications of the battery cell. In other words, Honda cannot and does not yet want to communicate how large the battery cells will be and what energy content (per cell or in the vehicle) is possible. The plan now is to test in Sakura how the results from the research can be transferred. Instead of announcing any figures, the tests will now provide data. Consequently, the long pouch cells, of which Honda has now published the first images, are only a prototype – and not (certainly) the final product.

The production process and system design are based on those of conventional lithium-ion batteries with liquid electrolyte. However, there are also deviations: For example, Honda writes of a “roll-pressing technique” that contributes to an increased density of the solid electrolyte layer. Of course, this is only relevant for solid-state batteries with solid electrolyte.

“With the adoption of the roll-pressing technique, Honda will strive to increase the degree of interfacial contact between the electrolyte and the electrodes and also increase overall productivity. Moreover, by consolidating and speeding up a series of assembly processes, including the bonding of positive and negative electrodes, Honda will strive to significantly reduce the production time per cell,” the Japanese company writes. That will help bring down indirect costs, for example, power consumption. Scaling effects should further reduce costs. “by expanding application of the batteries to a wide range of Honda mobility products, not only automobiles but motorcycles and aircraft, Honda aims to further reduce battery costs by taking advantage of economies of scale,” Honda explains.

‘’The all-solid-state battery is an innovative technology that will be a game changer in this EV era. Replacing engines that have been supporting the advancements of automobiles to date, batteries will be the key factor of electrification,’ says Keiji Otsu, President and Representative Director of Honda R&D. “We believe that advancement of batteries will be a driving force in the transformation of Honda. Now, the start of operation of our demonstration production line for our all-solid-state batteries is in sight, and we can say that we have reached an important milestone for Honda and the country of Japan.”

0 Comments