Georgia Tech researchers develop iron chloride-based cathodes

The revolution of the battery market has been announced many times before, but rarely has this promise been kept. It is usually startups looking for investors that make such announcements, but in this case, it is the Georgia Institute of Technology that believes its new cathode material will revolutionise the market for EV batteries and energy storage systems.

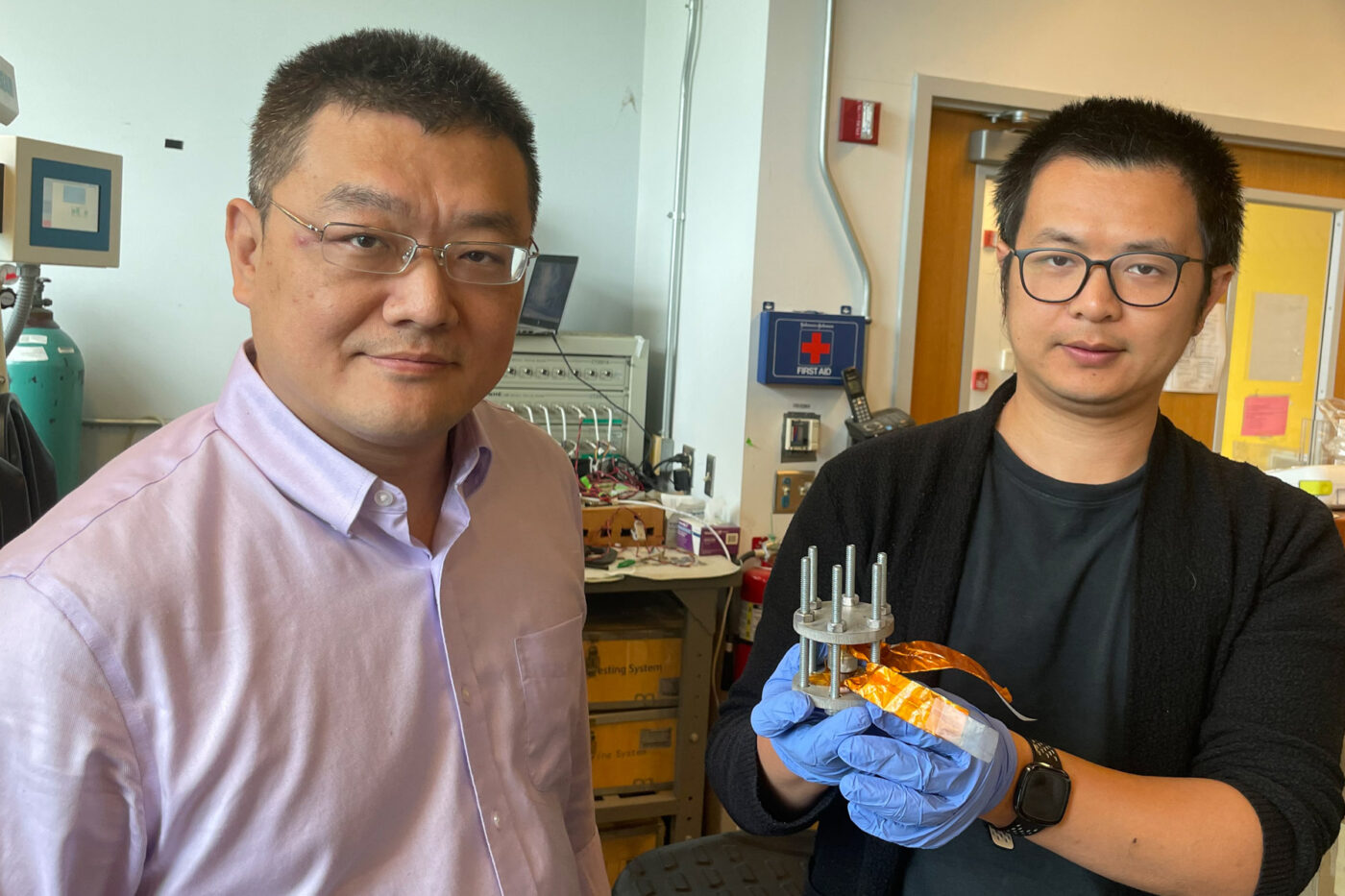

Scepticism is also called for in this case: the researchers have so far only tested their new cathode material on a laboratory scale and state in the announcement that the technology could be “less than five years from commercial viability in EVs.” For the time being, Hailong Chen’s team from the Georgia Institute of Technology will continue to investigate the ferric chloride in batteries as well as related materials.

But what is it all about? Hailong Chen, an associate professor at the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering, and his colleagues have developed what they claim is a cost-effective and sustainable solution for a solid-state battery. With an FeCl3 cathode, a solid electrolyte and a lithium metal anode, the cost of their entire battery system is 30-40 per cent of the cost of current lithium-ion batteries.

“For a long time, people have been looking for a lower-cost, more sustainable alternative to existing cathode materials. I think we’ve got one,” says Chen. “Our cathode can be a game-changer.”

Since 2019, the laboratory has been trying to produce solid-state batteries using chloride-based solid electrolytes with conventional commercial oxide-based cathodes. The press release states: “It didn’t go well — the cathode and electrolyte materials didn’t get along.” So in the next experiment, a chloride-based cathode was tested with the chloride electrolyte.

“We found a candidate (FeCl3) worth trying, as its crystal structure is potentially suitable for storing and transporting Li ions, and fortunately, it functioned as we expected,” says Chen. “This could not only make EVs much cheaper than internal combustion cars, but it provides a new and promising form of large-scale energy storage, enhancing the resilience of the electrical grid.”

Their initial tests showed that FeCl3 worked just as well or better than the other, much more expensive oxide-based cathodes, such as nickel oxide, cobalt oxide and manganese oxide. For example, it has a higher operating voltage than the frequently used cathode LiFePO4 (lithium iron phosphate or LFP).

One caveat remains: As mentioned, this is still research on a laboratory scale – when switching from small button or pouch cells to large-format cells with an energy content suitable for electric cars, there are usually still numerous challenges to be solved in order to transfer the positive properties of a new type of battery. “We want to make the materials as perfect as possible in the lab and understand the underlying functioning mechanisms,” says Chen. “But we are open to opportunities to scale up the technology and push it toward commercial applications.”

0 Comments