Chinese researchers discover new recycling method for NCM batteries

In their quest to find a simple, highly efficient, inexpensive, and environmentally friendly process for the recycling of depleted lithium-ion batteries, researchers from China University of Mining and Technology (Beijing), Fuzhou University, Beijing University of Chemical Technology, and Tsinghua University, Shenzhen (China) have formulated a novel citric-acid-based method for the leeching, separation, and reclamation of metals from NCM cathodes.

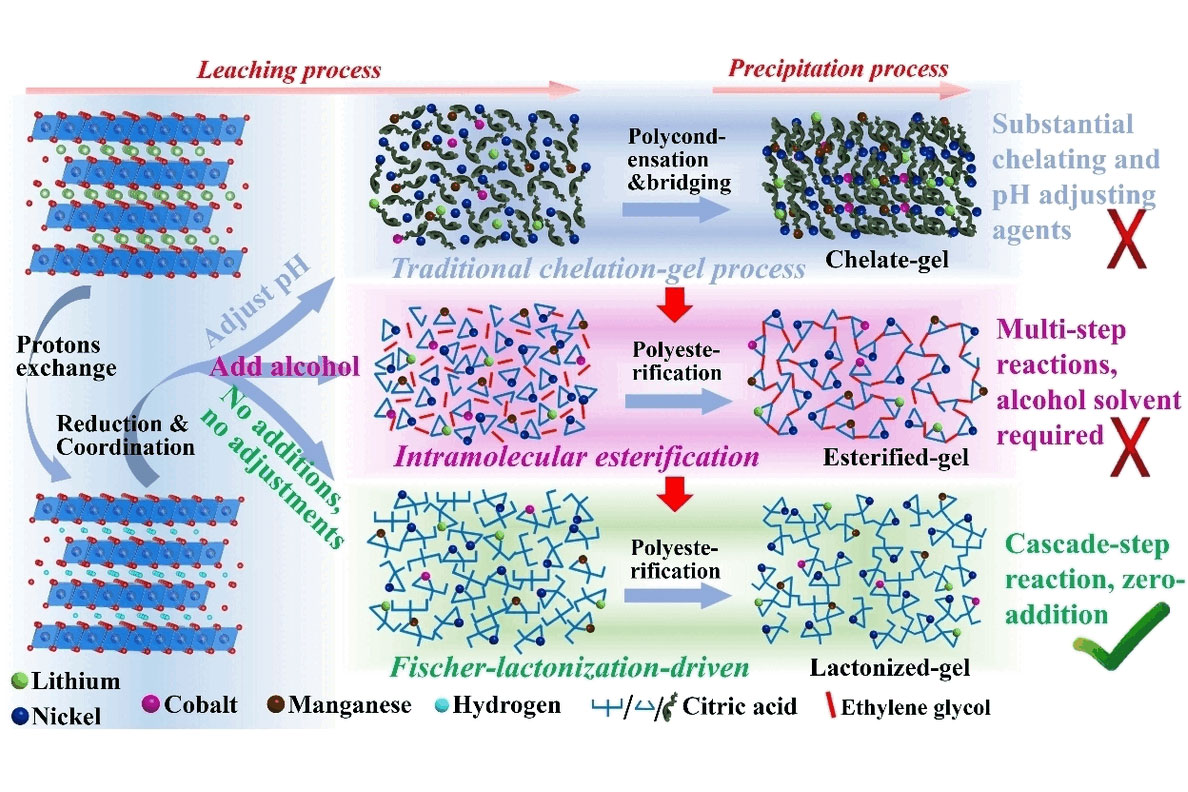

Unlike conventional methods, the researchers used a relatively small amount of citric acid to leech out and separate over 99% of the lithium, nickel, cobalt, and manganese metals in NCM batteries. No other chemicals were used in the experiment. This leaching method consumes less energy. On top of that, CO2 emissions are significantly lower than those of conventional hydrometallurgical recycling processes. The researchers claim that the experiment yielded a “new NCM lamellar framework” product, which can be used “as a high-quality electrode material.”

The article was first published in the Journal of the German Chemical Society called Angewandte Chemie in October.

NCM is a mixed metal oxide combining nickel, cobalt, and manganese in a lamellar structure, with Lithium ions between the layers. While NCM batteries find applications in mobile phones and electric vehicles, they have a limited lifespan. According to Dr Ruiping Liu, who heads the team of researchers, battery recycling processes are energy-intensive, have high emissions, and limited or low-quality recovered material. Moreover, the traditional leaching process involves the excess use of chelating agents in a complicated process that is also hazardous to the environment.

0 Comments