Deep Dive MMA: How Mercedes wants to score points with efficiency with the electric CLA

Granted, Mercedes has already placed a particular emphasis on efficiency with the EQS and its particularly aerodynamic body. However, talking about efficiency in a luxury vehicle weighing over 2.6 tonnes with a peak output of up to 560 kW is relative. It is also clear that the original EQS concept did not do well in China, which is an important market for luxury saloons.

The upcoming CLA, which is based on the Mercedes Modular Architecture (MMA), is expected to be much more successful. Next year, the compact saloon will be the prelude to the German carmaker’s upcoming compact model family, set to generate high unit sales. There is a simple reason why the MMA will not be making its debut in a new A-Class: the model portfolio is being radically streamlined, and there will be no successors to the A- and B-Class. Instead, there will be the CLA, a shooting brake as a dynamic estate and two SUV models – one a little more dynamic in the style of the GLA/EQA and the other more angular with more space and utility value like the GLB/EQB.

However, the details of the four models have yet to be finalised, and Mercedes is not yet willing to comment further on the vehicles. Instead, the car manufacturer organised a technology workshop on the MMA at the Sindelfingen plant in Germany, specifically in the ‘Electric Software Hub,’ where a large part of the development work on the new platform took place. Mercedes wanted to share information about the drives, some statements about the batteries, and how the MMA was developed with the public. The details of the CLA will be revealed at the world premiere next year. However, we can already get an idea about what will be under the bonnet.

Efficiency is at the centre of the development. As Torsten Eder, Vice President Development Electrified Drives, explained in his presentation, his team not only focussed on classic energy efficiency, but also on what Mercedes calls ‘time efficiency.’ Because from the customer’s point of view, it’s all about arriving at the destination as quickly as possible – be it due to a long range thanks to the efficient drive, short charging times or intelligent charging planning. Everything plays a role.

At Mercedes, they are sure that they are on the right track. “In our opinion, efficiency will make the difference in future electric models,” said Eder. And: “Efficiency is the new currency.”

The CLA and all other electric Mercedes models will have to be measured against this sentence. A consumption of 12 kWh/100 kilometres has been announced for the first MMA model. The following chapters show how this is to be achieved.

The drive

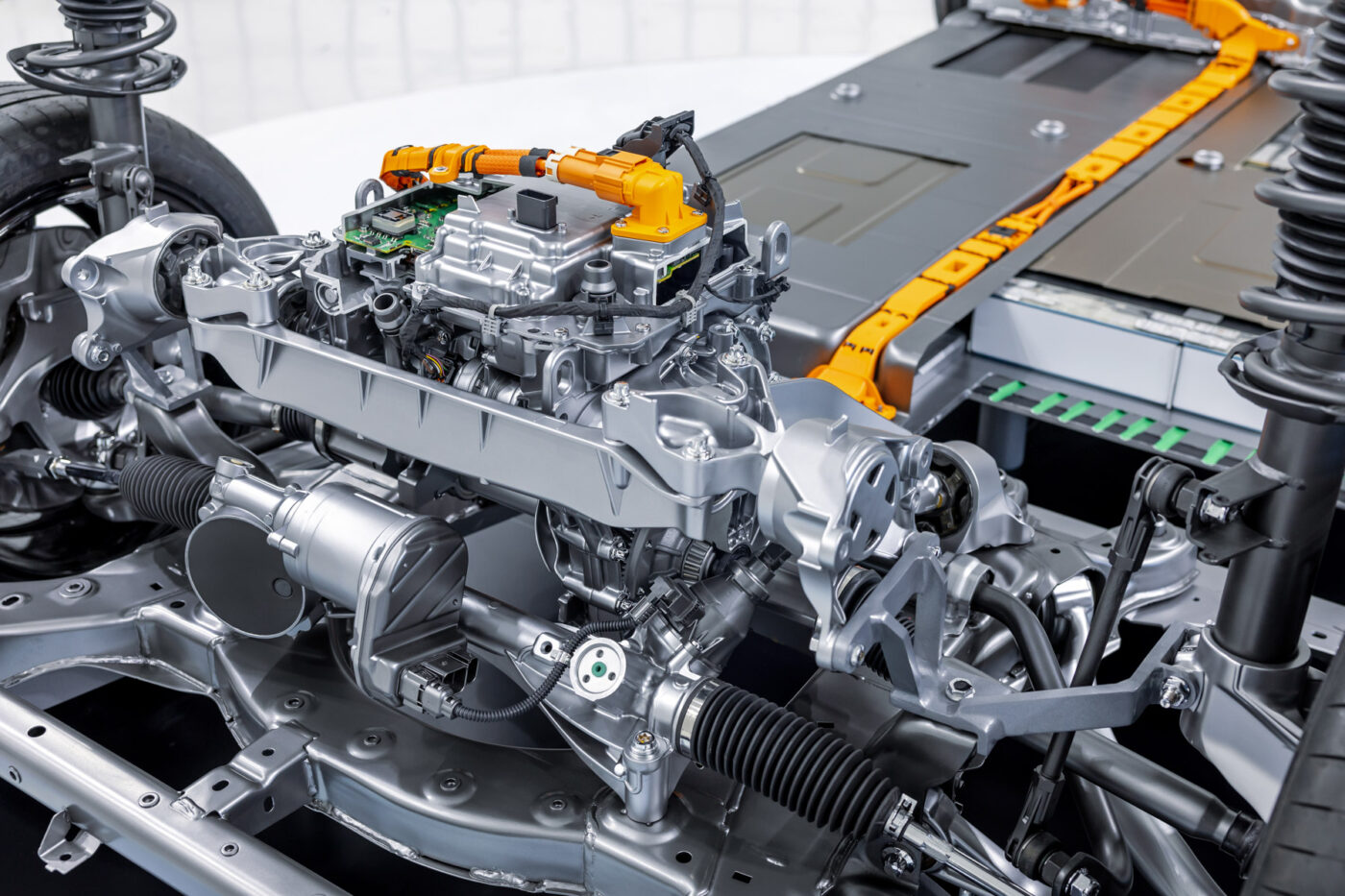

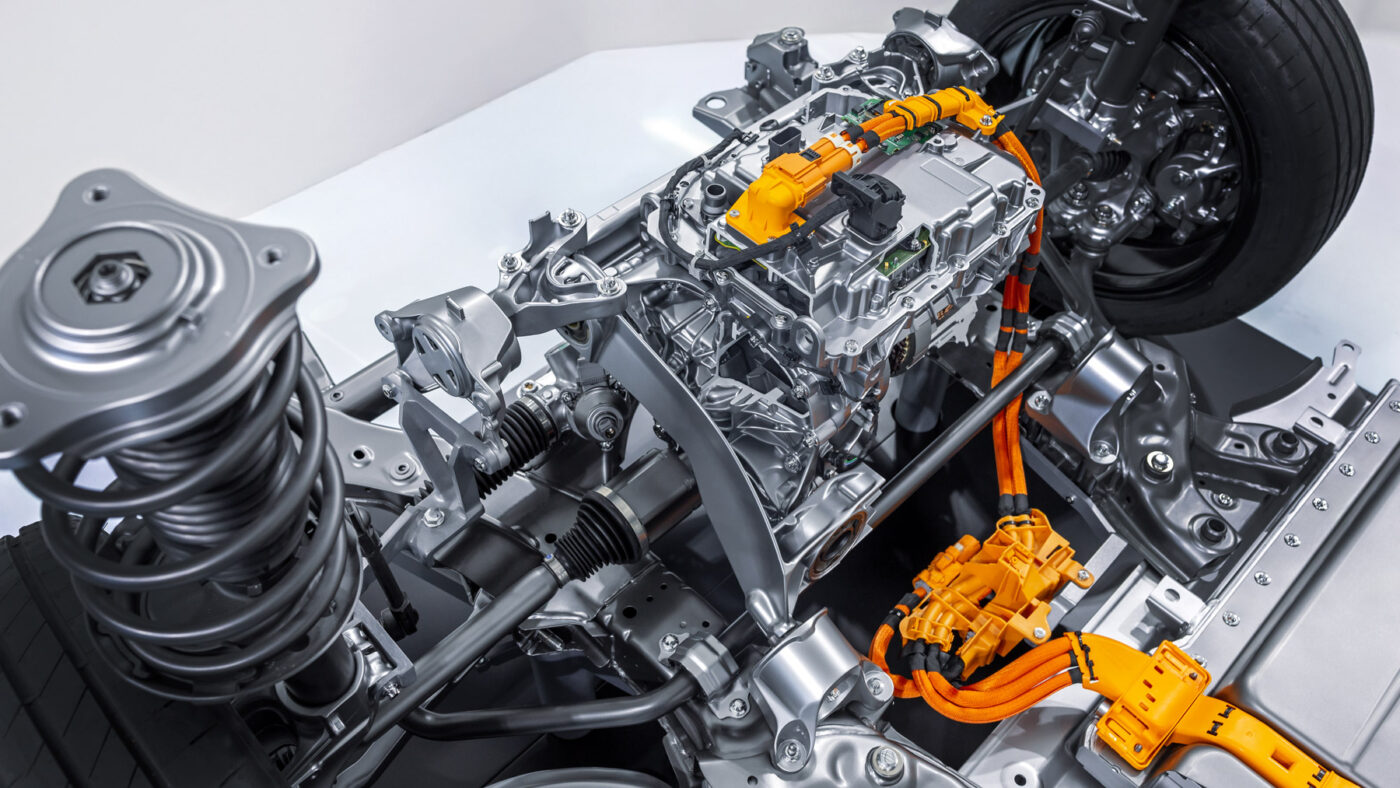

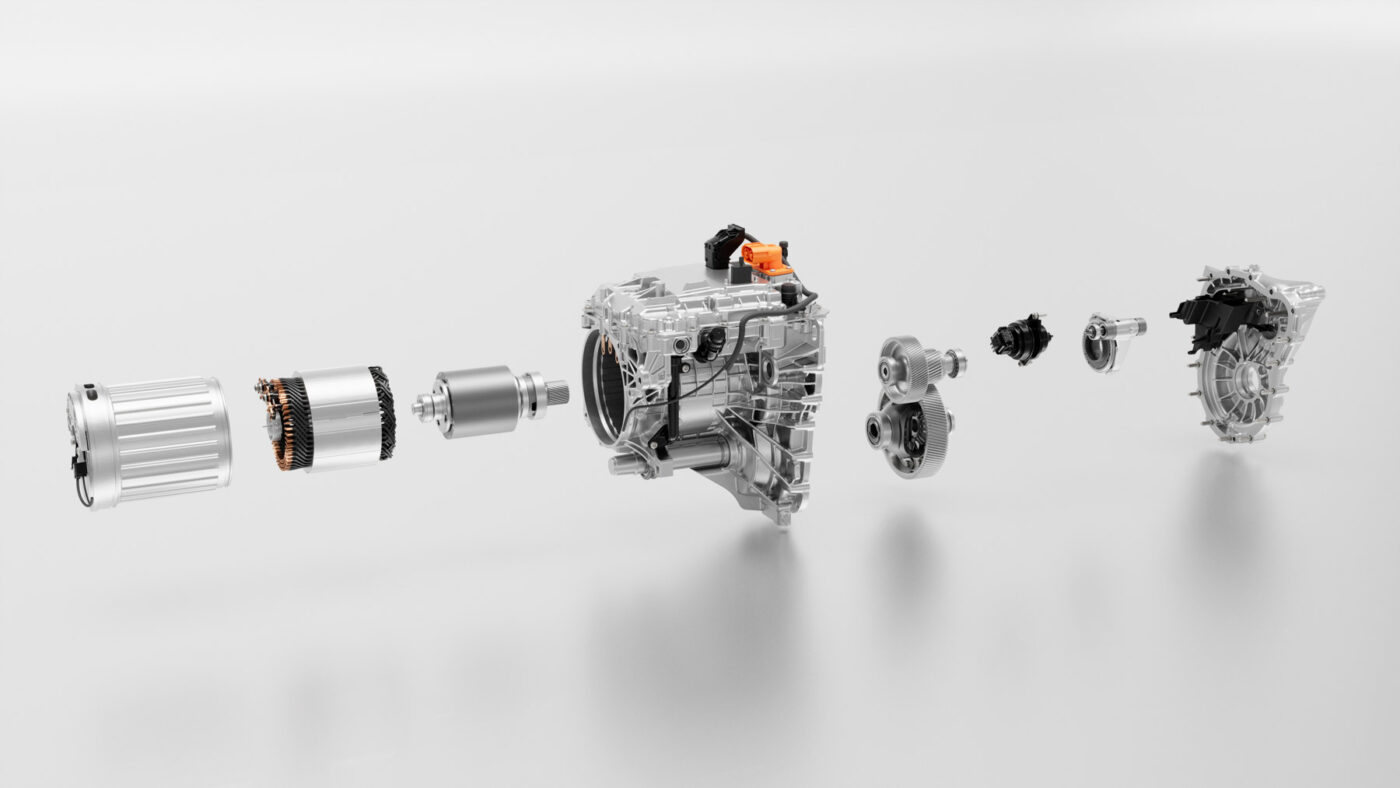

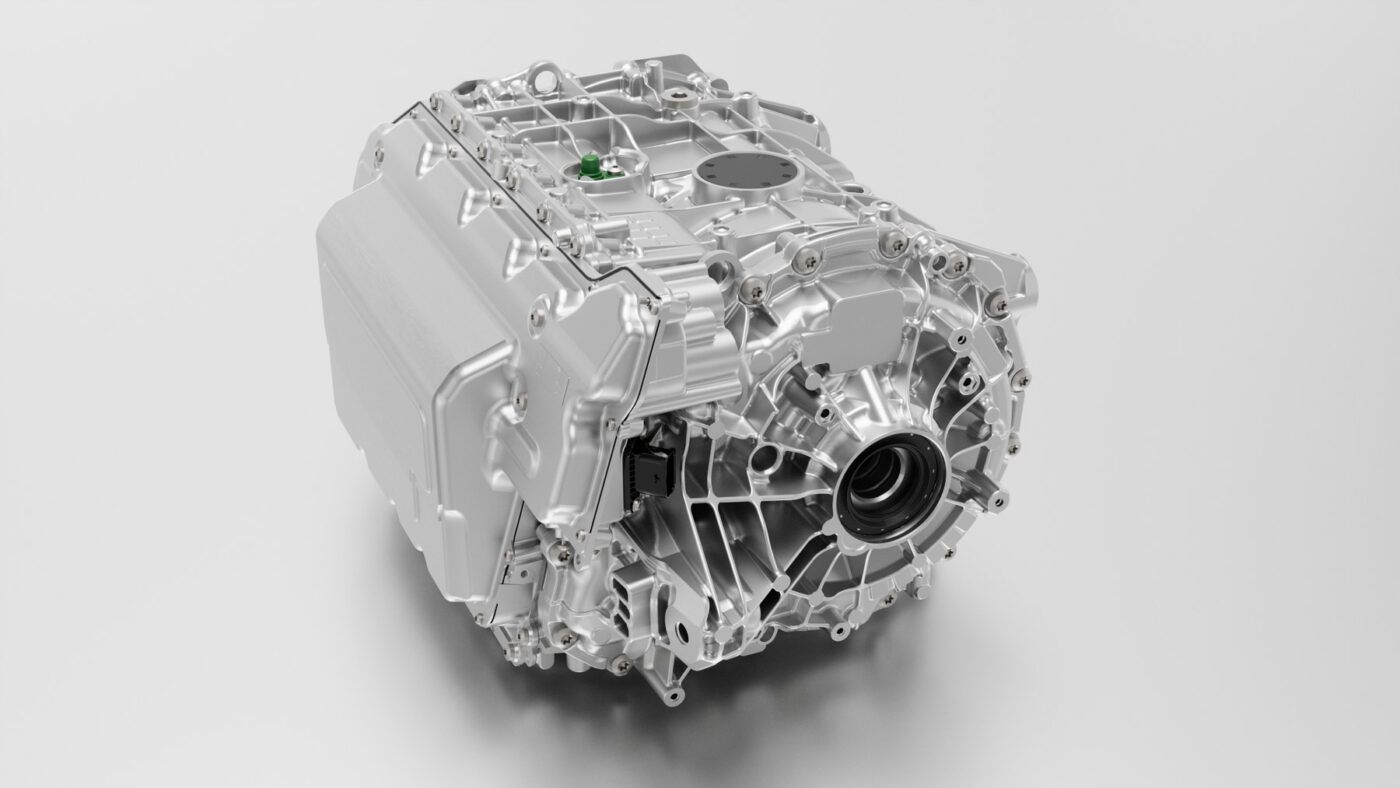

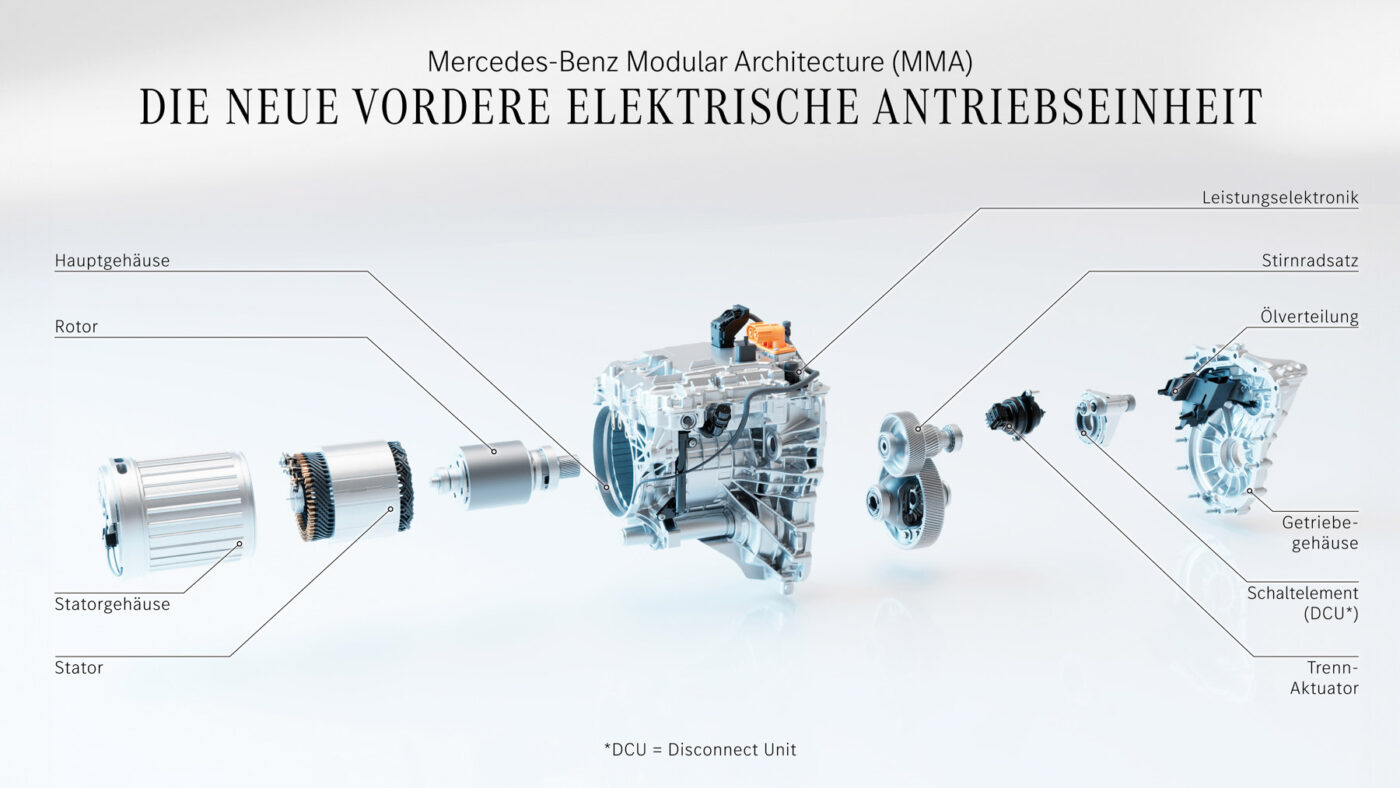

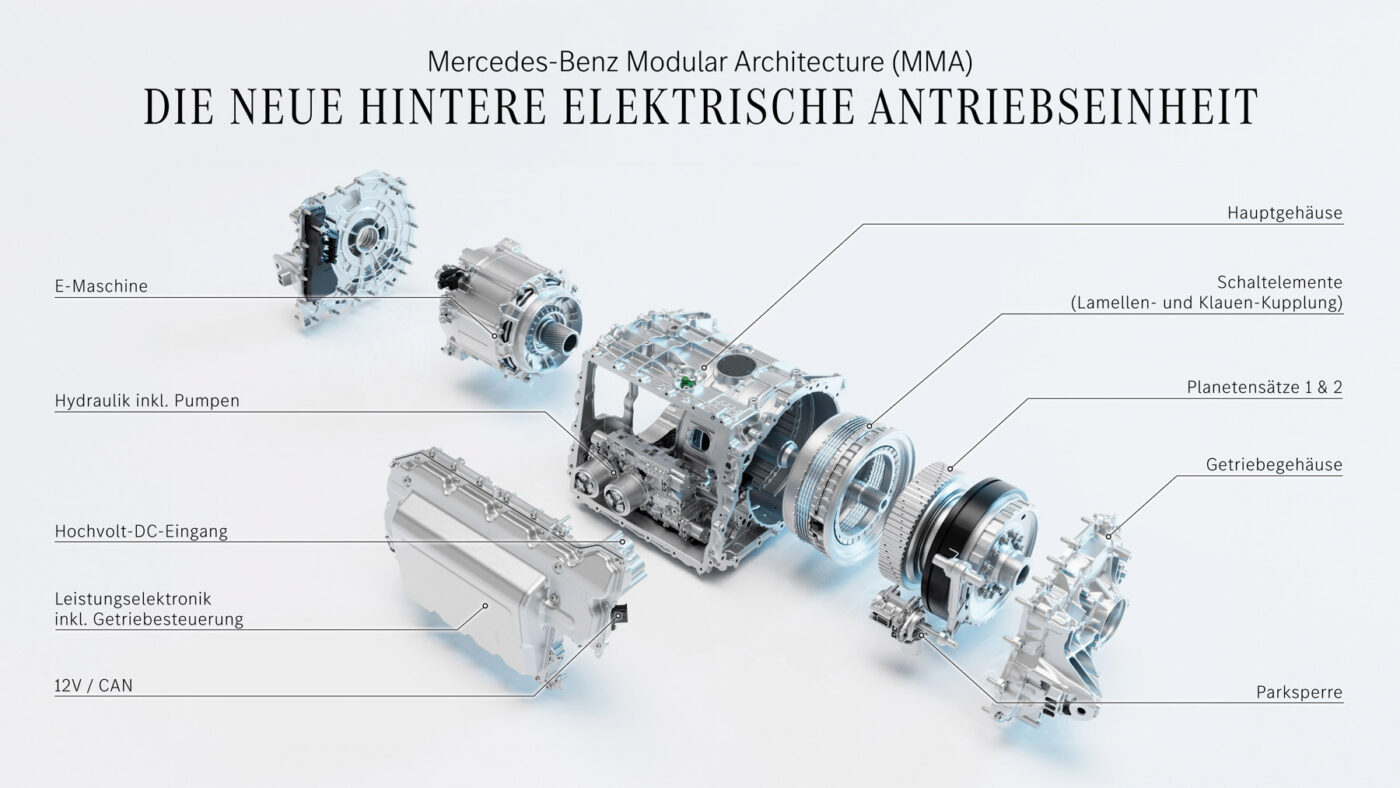

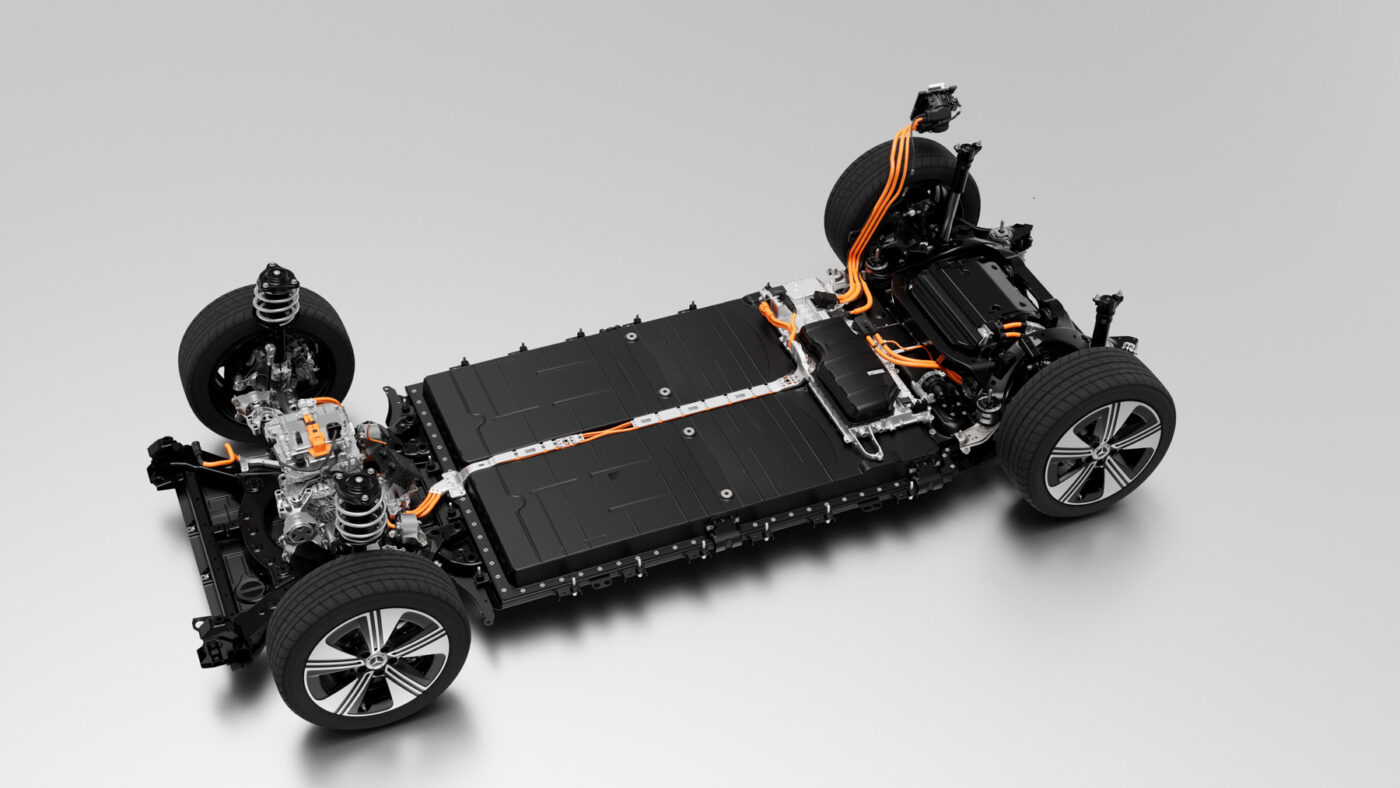

The CLA utilises the new eATS 2.0. As Eder explained, this “electric powertrain 2.0” (also known as MB.EDU 2.0) is a kind of electric motor family – the first of four “family members” is installed in the CLA. It is a highly integrated electric motor that Mercedes developed itself and manufactures at its main plant in Untertürkheim.

One small but: only the electric motor on the rear axle is such an eATS 2.0. The second electric motor, installed on the front axle in the all-wheel drive version, was also developed according to Mercedes specifications but comes from a supplier.

The eATS 2.0 is a permanently excited synchronous machine (PSM). The peak output is 200 kW. The drive unit is very compact and designed to allow a large, deep boot. The power electronics (SiC semiconductors are used at the front and rear) are positioned roughly at the front of the housing, no longer at the top. Despite the permanent magnets, the PSM manages “almost” without rare earths, as Christian Pfeffer, project manager for series development of the CLA drivetrain, explained. The carmaker achieved this by using hairpin windings in the stator and a double-V arrangement of the permanent magnets in the rotor.

Probably the most controversial part of the electric drive in the CLA is that the drive unit in the rear has a two-speed gearbox. Porsche once opted for a two-speed gearbox on the rear axle in the Taycan to harmonise the required acceleration and high top speed. This has not found many imitators since then, and even the Macan only has one gear at the rear. For Mercedes, however, the focus was not really on dynamics but, above all, on efficiency.

“With two gears, we can achieve high efficiency in an extremely wide range,” explained Pfeffer. There is no specific speed at which the multi-plate clutch and jaws change gear. “We constantly calculate which gear is more efficient,” the developer added. “It depends on the load, the selected driving mode, and factors such as the battery voltage.”

For the sake of completeness: the first gear ratio is 11:1, and for the second gear, the ratio is 5:1. Above 110 kph, the second gear is always engaged, while the first gear is engaged when pulling away – in between, the control unit decides.

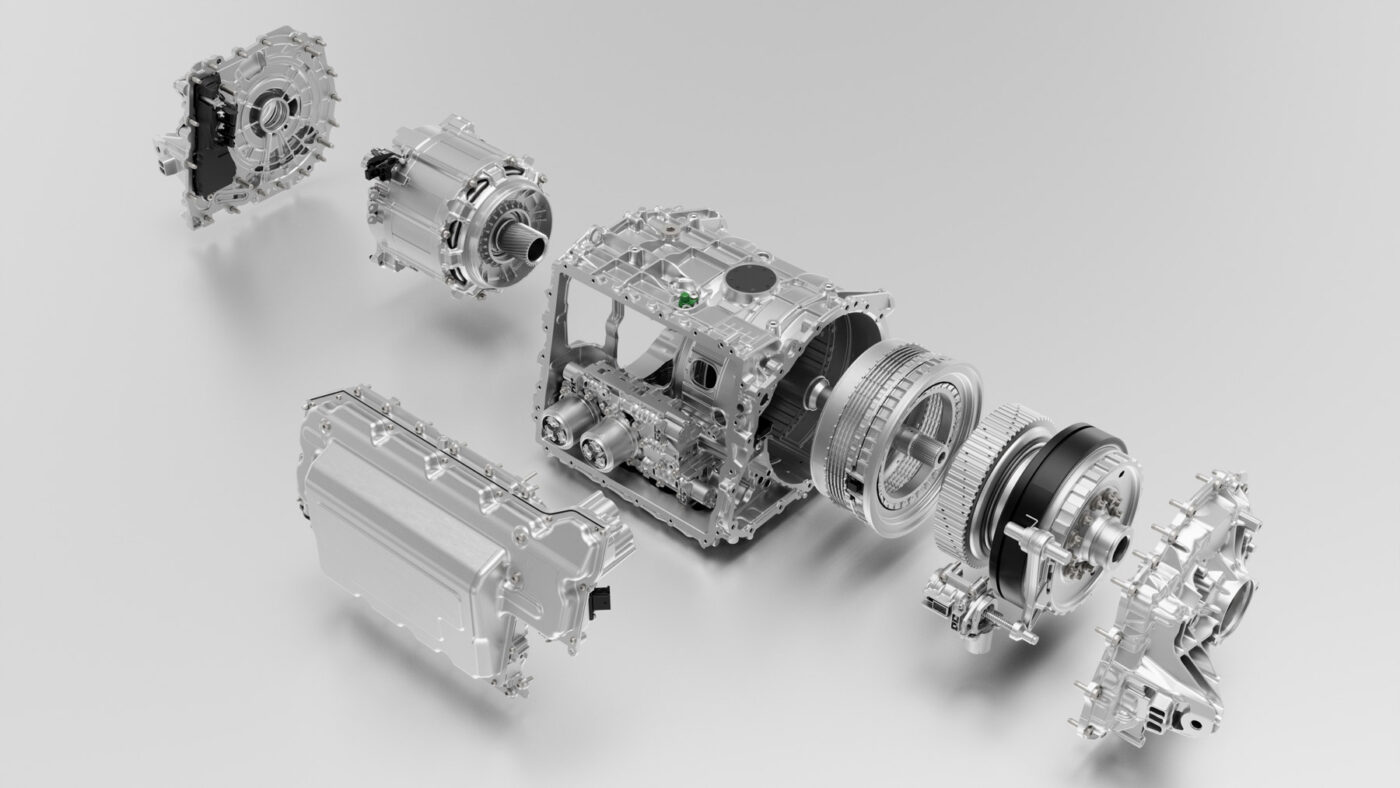

An additional PSM with 80 kW is used at the front in the all-wheel drive models. This is used as a boost unit for starting off and under high load. For most everyday driving at a constant speed, this engine is mechanically disconnected via a separate clutch in the so-called ‘disconnect unit.’ That happens within 0.2 seconds – so the front engine can also be quickly engaged for recuperation. The CLA will again have four recuperation levels – from One-Pedal-Drive to automatic D-Auto control. Despite its gearbox, the rear drive unit is not disengaged. Even when sailing, the electric motor remains mechanically connected to the wheels and is merely de-energised. Pfeffer stated that “as much as possible is switched off when stationary to save every watt.”

Even when asked directly, Mercedes will not yet comment on whether further power levels of the 200 kW drive unit are planned (for example, with the smaller battery option). What is clear, however, is that the same drive hardware will always be installed regardless of the battery – with whatever output. It is also clear that this basic concept will appear in other models, not just the four MMA electric vehicles. “The powertrain that we have developed for the MMA is scalable – even in other architectures,” said Torsten Eder. “We can also adopt several technologies in other vehicle classes and thus create synergies.”

The battery

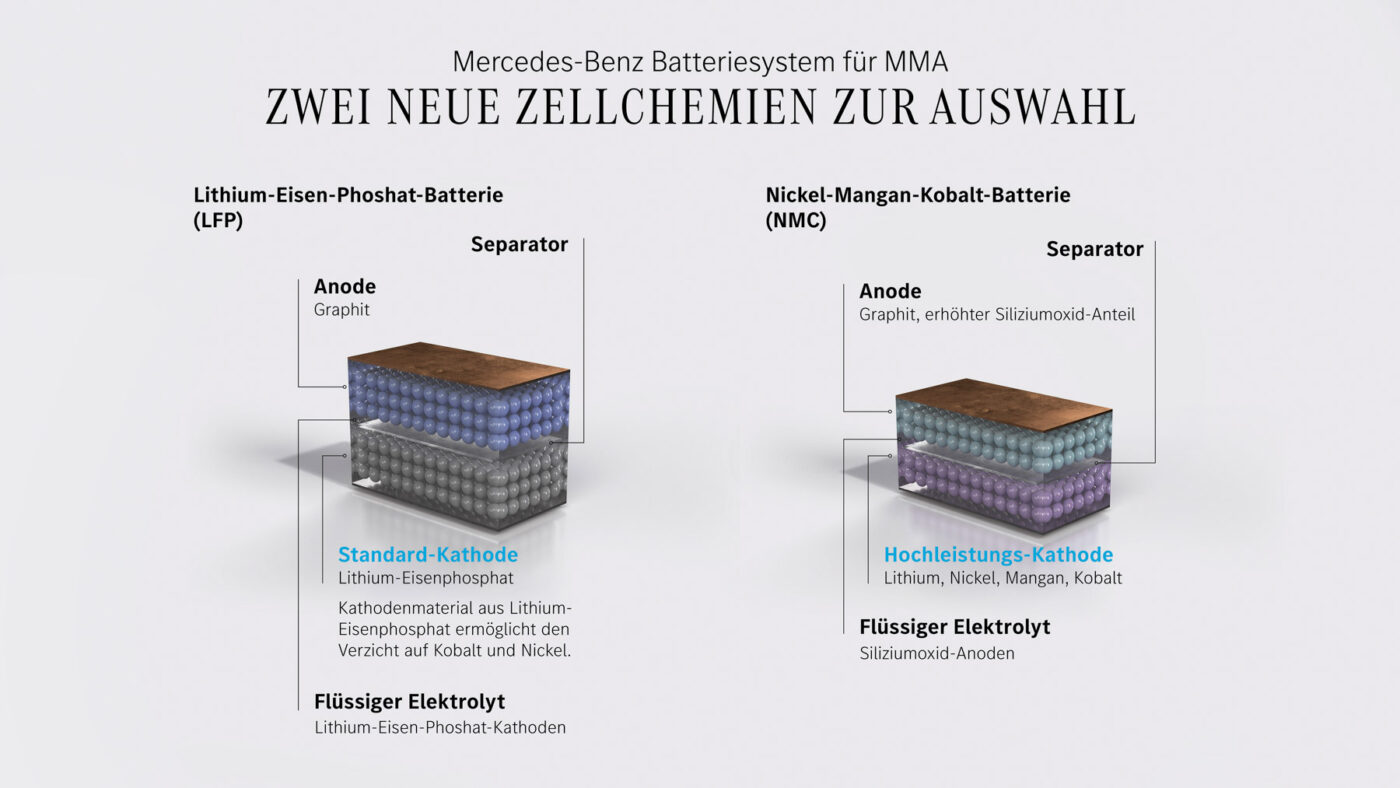

The same applies to the battery: the MMA does not feature any special developments for the platform. It is a modular system whose technologies will also be used in larger models at a later date. Although the Stuttgart-based company does not have a dedicated ‘unified cell’ like the competition from Wolfsburg, it does have a similar concept. Mercedes wants to control the scaling of the cells via two dimensions: the cell chemistry and the size of the cells – the height in particular.

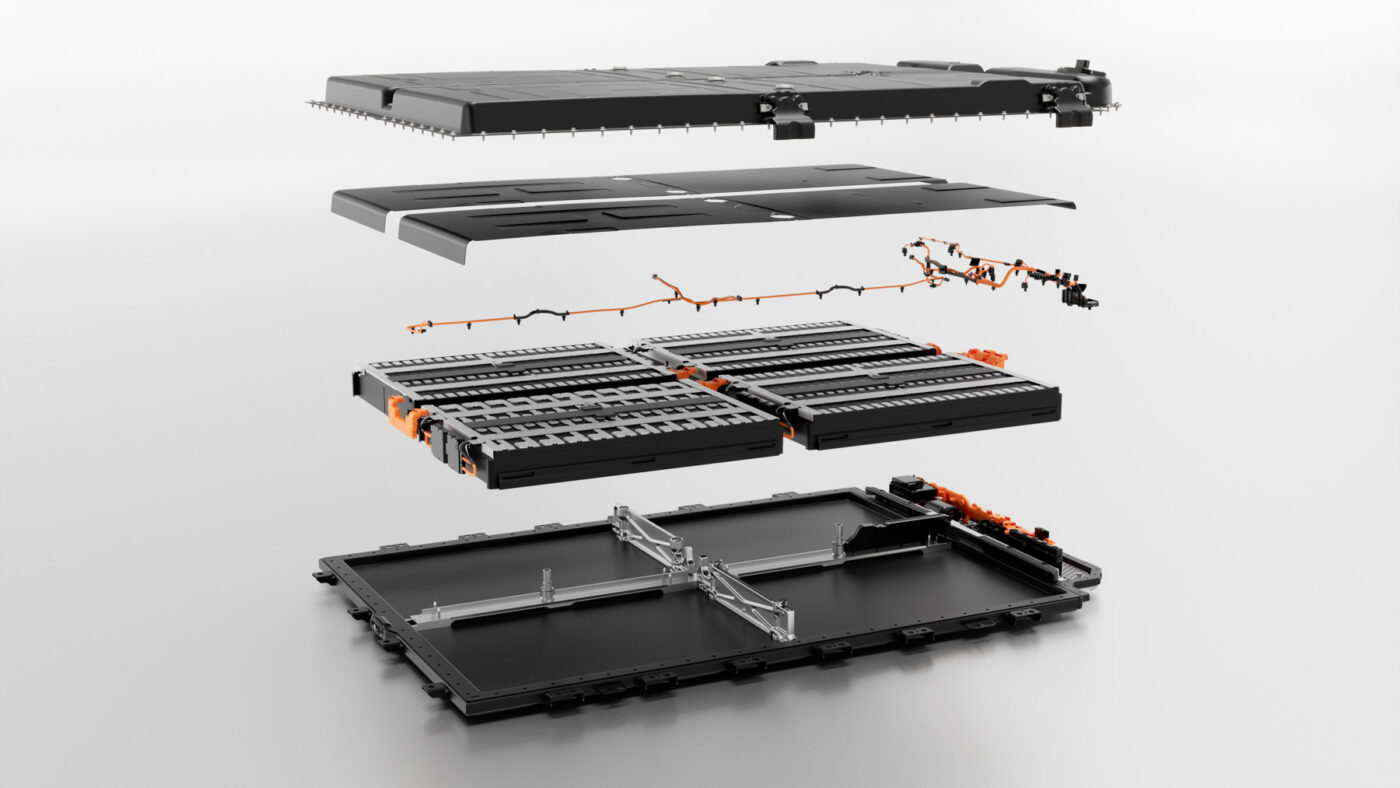

In the CLA, the battery pack with 192 prismatic cells is very flat – at the workshop in Sindelfingen, there was talk of a “remarkably” low overall volume of the pack. That is more than just the result of the work of the in-house battery developers. “We liaised with our vehicle colleagues early in the development process,” said Uwe Keller, Head of Battery Systems Development.

In order to achieve such a flat battery, Mercedes first had to do a lot of groundwork. New paths were taken to strengthen expertise and development internally. For example, Mercedes now controls all sensors and actuators (e.g. in the cooling circuit) in the battery itself with its software. “We have procured virtually empty control units from our suppliers,” said Eder. In the past, Mercedes purchased the corresponding software, sensors, and control units. And with the e-Campus in Untertürkheim, the company has also expanded battery development at cell level.

Keller describes battery development itself as “a decathlon.” A decathlete has to find the optimum compromise between his disciplines – an outstanding runner can score points in many areas but may fall short in the shot put, javelin throw or pole vault if he does not train in a balanced way. Applied to the battery, it means that when it comes to the weighting of factors such as charging power, discharging power for the drive, design/pack, weight, costs and range, it is possible to prioritise, but a compromise is always required. “Safety and sustainability, for example, were non-negotiable for us. We made no compromises here,” said Keller.

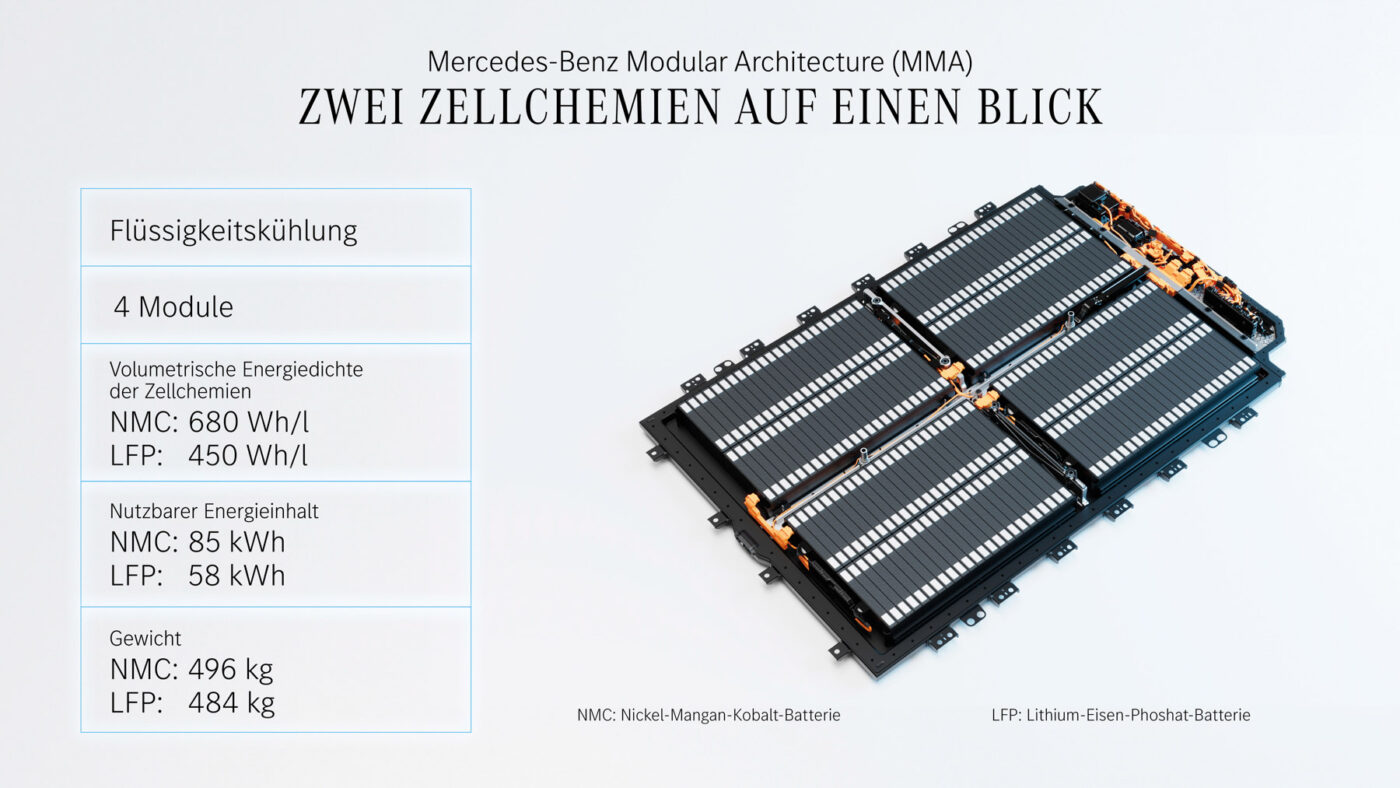

The result: there will be two battery options in the CLA (for the time being). Mercedes will use LFP cells in the entry-level version to offer a lower price. The larger version for the maximum range (750 kilometres is the target) will use NMC cells with a silicon-containing anode – a first at Mercedes. Both battery packs are the same size and weigh roughly the same. With the higher energy density, the NMC pack has 85 kWh and the LFP battery 58 kWh – both are net values, i.e. the actual usable energy content.

Mercedes states an energy density of 450 Wh/l for the lithium iron phosphate chemistry and 680 Wh/l for the NMC battery. That is 30 per cent more than before for the latter battery, and the gravimetric energy density has increased by 20 per cent compared to the current battery generations. And the whole thing is 30 per cent cheaper – Mercedes is not giving the absolute values here.

Battery developer Keller was also unwilling to comment on the exact proportion of silicon. When asked repeatedly, he only let slip with a wink that it is “less than 50 per cent” – but he would not comment whether it was five per cent, ten or 49.9 per cent. His colleague Franz Nietfeld from Cell Development added that they are already working on high-silicon anodes in the laboratory – but that these are not yet ready for series production.

So let’s stick to the known facts: The pack will be built in Kamenz, in the German state of Saxony – regardless of the cell chemistry – and delivered from there to the vehicle plants. Initially to Rastatt for the CLA, and later also to the Hungarian plant in Kecskemét.

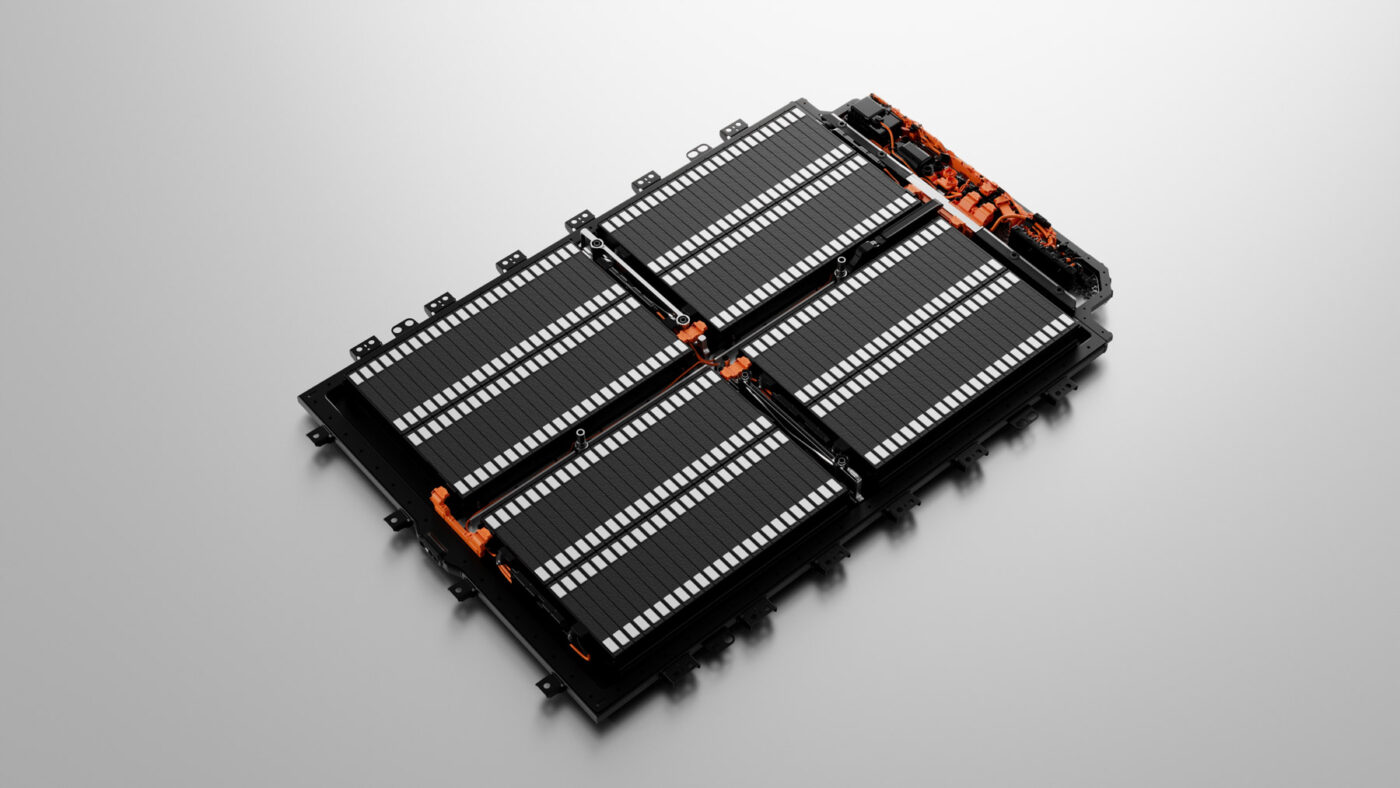

The 192 cells are combined into four groups of 48 cells each – 24 cells are arranged next to each other. The base of the battery pack consists of a steel frame with an aluminium tray, where the cooling system is also glued in – the cells are therefore only cooled or heated via the underside. The four cell groups are then glued into the pack. That has several advantages. Firstly, it simply increases rigidity and saves weight. Secondly, there are no chips during production, which helps with reliability and tightness.

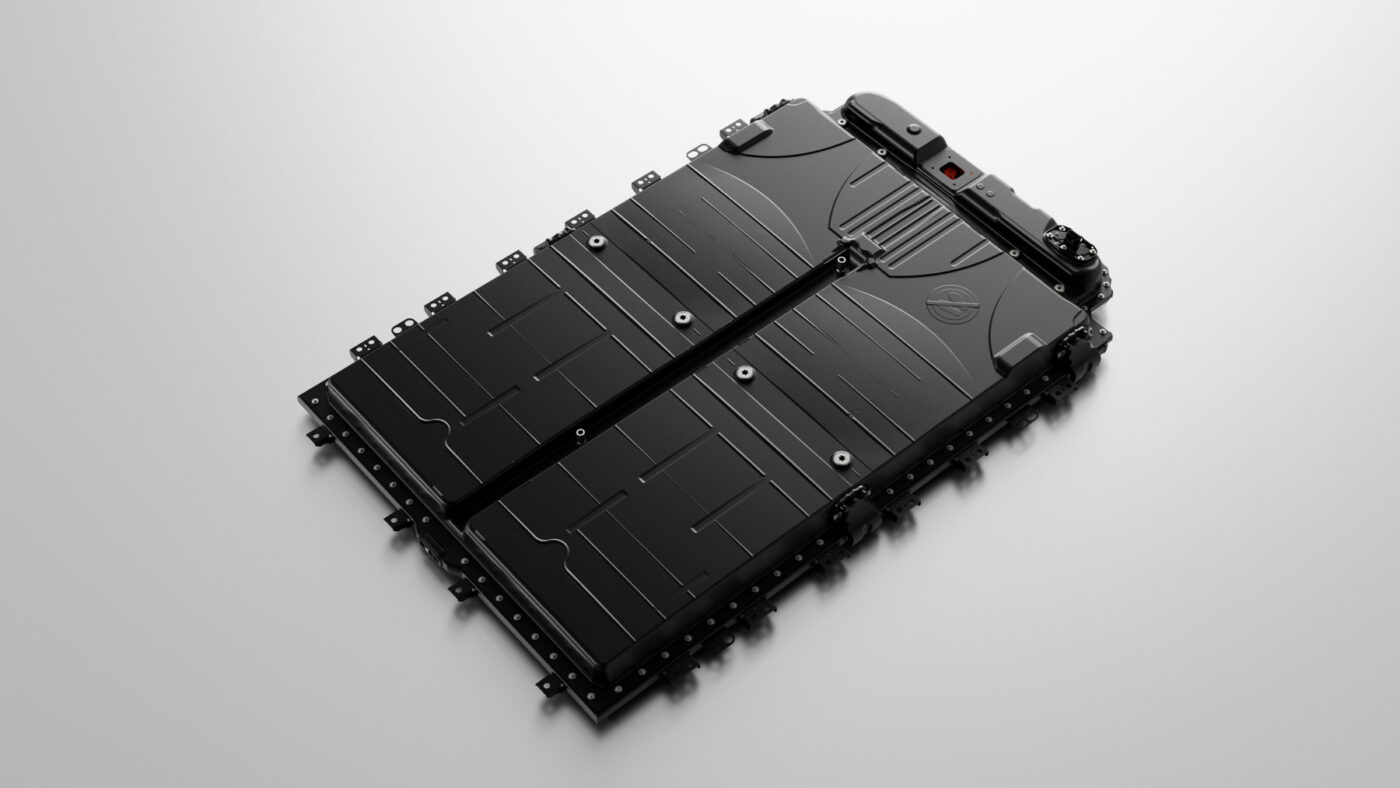

Keller also spoke of “a mixture of cell-to-module and cell-to-pack.” Yes, Mercedes also uses adhesives, but unlike a cell-to-pack concept, not everything is glued. With the MMA, for example, the battery cover can be unscrewed. As soon as the insulating layer underneath is removed, the modules, the wiring harness and all plug connections are accessible from above – and can be replaced individually in case of a defect.

Charging

That is where time efficiency comes into play. It is good for the range if the drive and body are efficient. However, if the customer then stands at the charging station for 40 minutes, they will not necessarily reach their destination any faster than with an electric car, which consumes a little more but charges much faster. At the event in Sindelfingen, Mercedes repeatedly emphasised the influence that the Vision EQXX concept car, also developed in the Electric Software Hub, had on the CLA and the MMA. The electric motor is “very similar” (albeit without a two-speed gearbox), as is the battery design. Mercedes did not mention that the CLA clearly stands out from the EQXX when it comes to charging. After all, the latter was built not to be charged for over 1,000 kilometres – the charging performance was correspondingly weak.

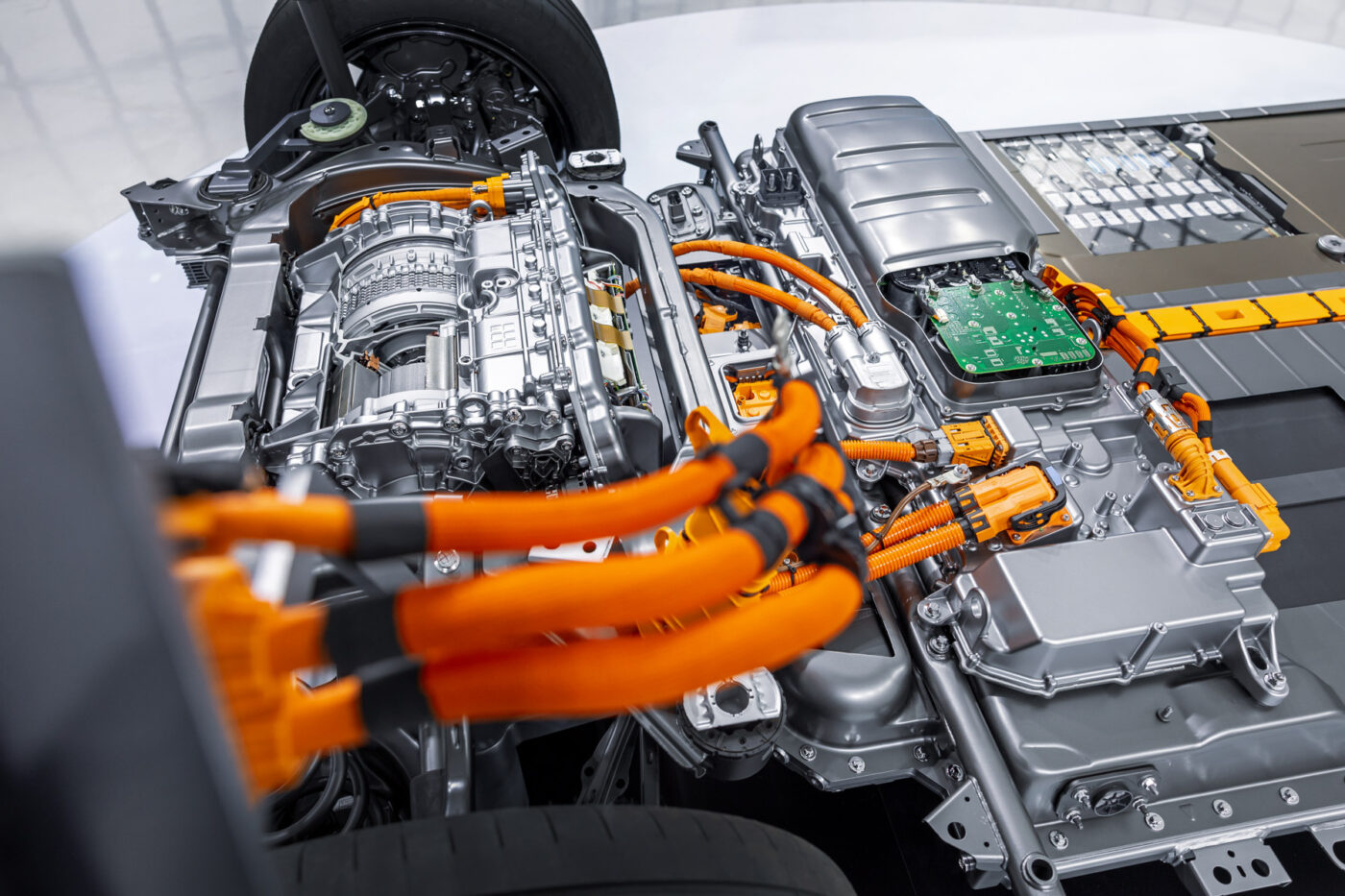

Of course, this must be different for a production car that will debut in 2025. Short charging times are important for customers. That’s why Mercedes opted for an 800-volt system for the CLA – unlike the large EQS. There are more factors in favour of 800 volts than just the charging power: the lower amperage for the same power means the cables can be thinner and lighter.

The charging power that the CLA achieves would not be easily possible with a 400-volt system and today’s charging infrastructure: the data sheet lists 320 kW at the peak. “What is much more important to us than the peak power: how much range can I recharge in ten minutes,” explained Torsten Eder. “We can achieve 300 kilometres here!” His developers later added that the charging time from ten to 80 per cent is less than 22 minutes. With two charging stops of ten minutes each, 1,200 kilometres should be possible.

All these figures refer to the 85 kWh NMC battery. No further details were given in Sindelfingen about the LFP variant with its 58 kWh. We will thus have to wait for the world premiere to find out more precise information about the charging behaviour.

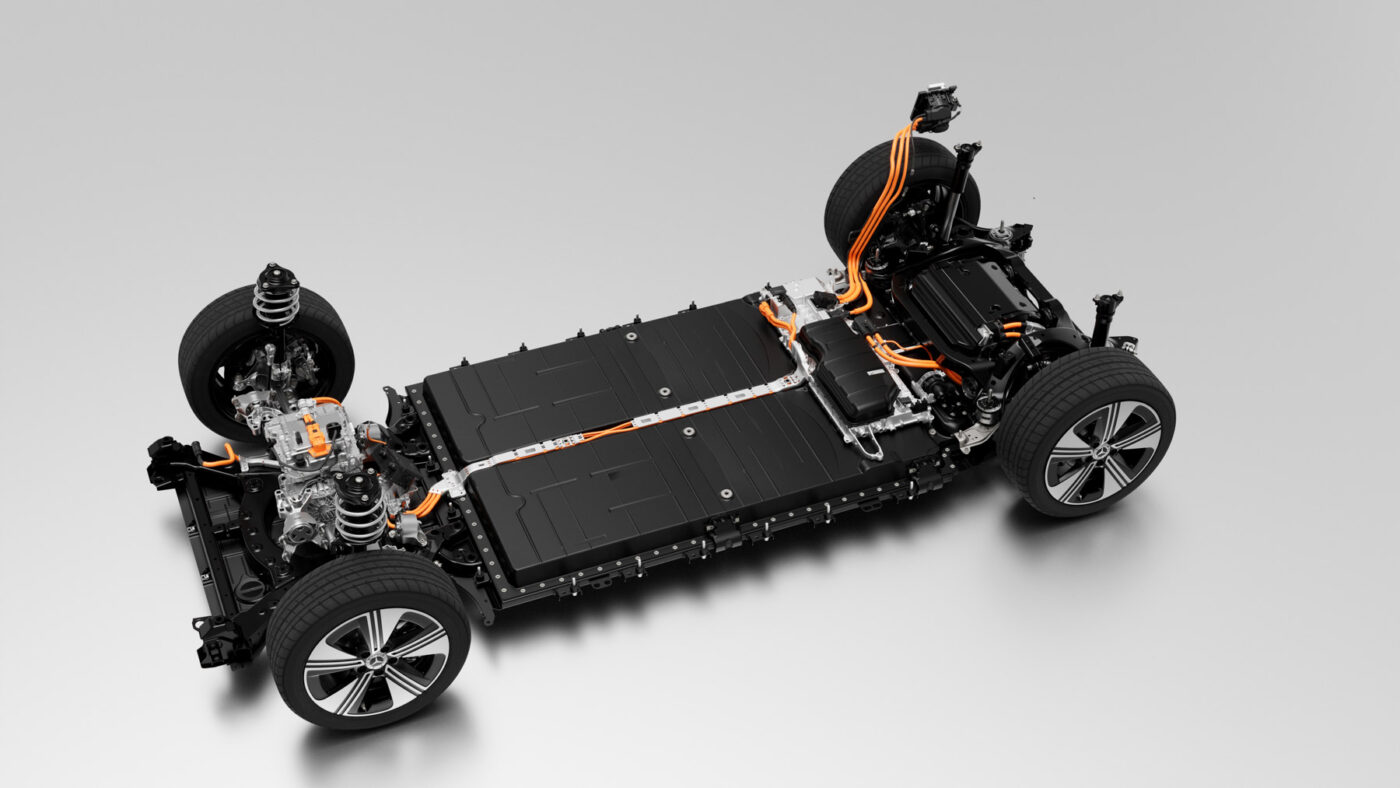

In terms of design, the charging system bears a certain resemblance to the VW Group’s PPE: The entire charging technology (for AC and DC) is installed at the rear on top of the battery pack – Mercedes calls the component ‘One Box.’ As the charging technology is located under the rear seats, at least the MMA electric vehicles will have the charging connection at the rear – a skateboard model on display in Sindelfingen had the CCS socket above the rear wheel on the passenger side. Efforts are being made to keep the high-voltage cables as short as possible for reasons of efficiency. However, it is conceivable that the charging port will be positioned elsewhere, for example, near the rear light – although the classic petrol cap position is more likely.

The hybrid

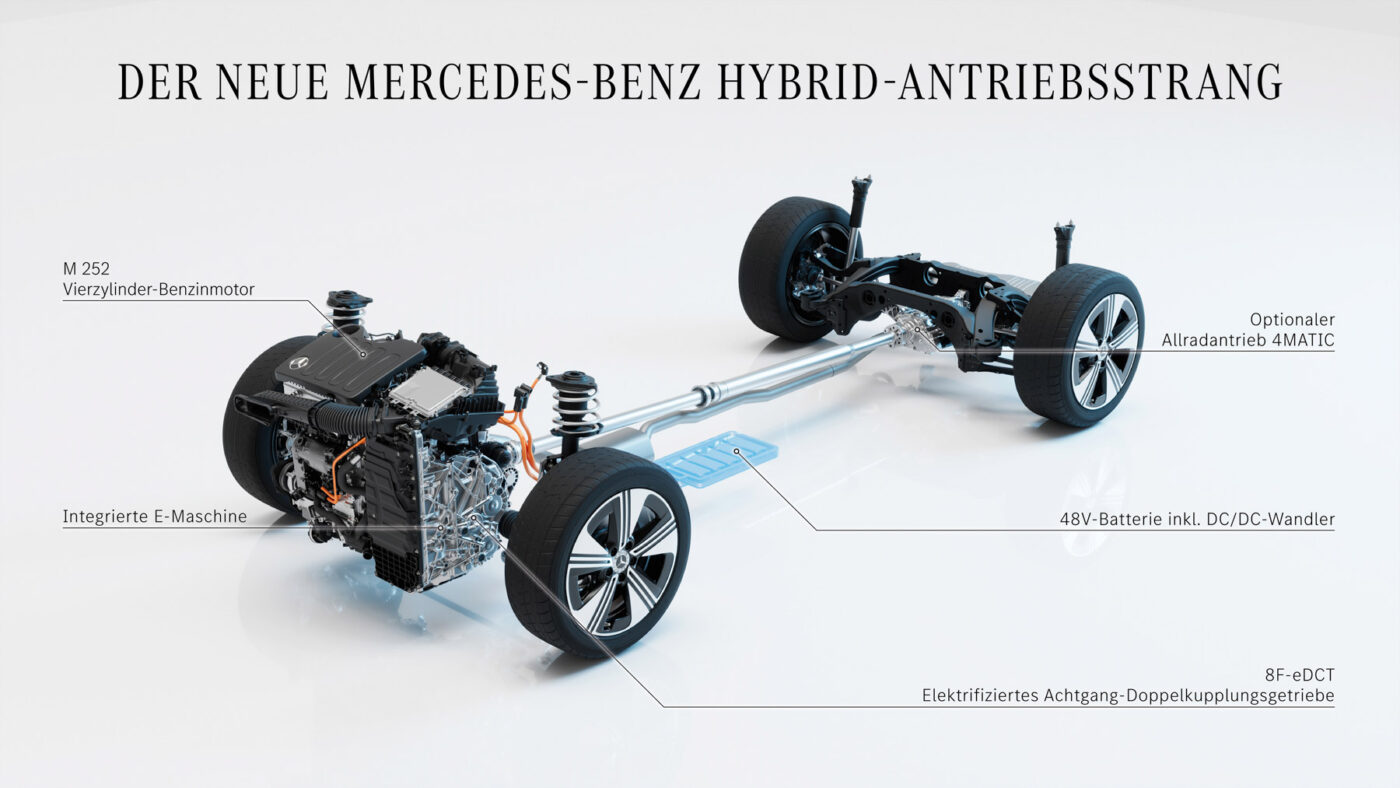

The upcoming hybrid version of the CLA should not be completely overlooked. Although the MMA was designed for battery-electric cars, it also enables a hybrid drive. It will launch after the BEV version and is worth mentioning for electrive for one reason: although it is only a 48-volt hybrid, the CLA can drive purely electrically.

Specifically, it is a P2 hybrid, with the electric motor (also a PSM here) acting on the input shaft of the eight-speed dual-clutch transmission with the unwieldy name 8F-eDCT. This means it is possible to drive in all eight gears with electric support and recuperate. As a third clutch is installed in the compact electric motor-transmission unit, the combustion engine can be completely disconnected. The 20 kW of the electric motor can then be used to drive purely electrically – not only slowly in the city, but also, according to the developers during the test drives, at speeds of up to just over 100 kph if the speed is to be maintained at a constant speed.

The battery has a capacity of 1.3 kWh, of which only 800 watt hours are intended for driving. Mercedes will not communicate a purely electric range and will not have it certified.

The combustion engine is a newly developed 1.5-litre four-cylinder engine. Due to the limited installation space designed for a small electric motor and a frunk in the electric car, the entire hybrid must be extremely compact. Three power levels with 100, 120 and 140 kW are available. Mercedes-Benz developed the M252 turbo petrol engine, but it is not built in a Mercedes plant. Instead, it is built by the Geely subsidiary Aurabay China.

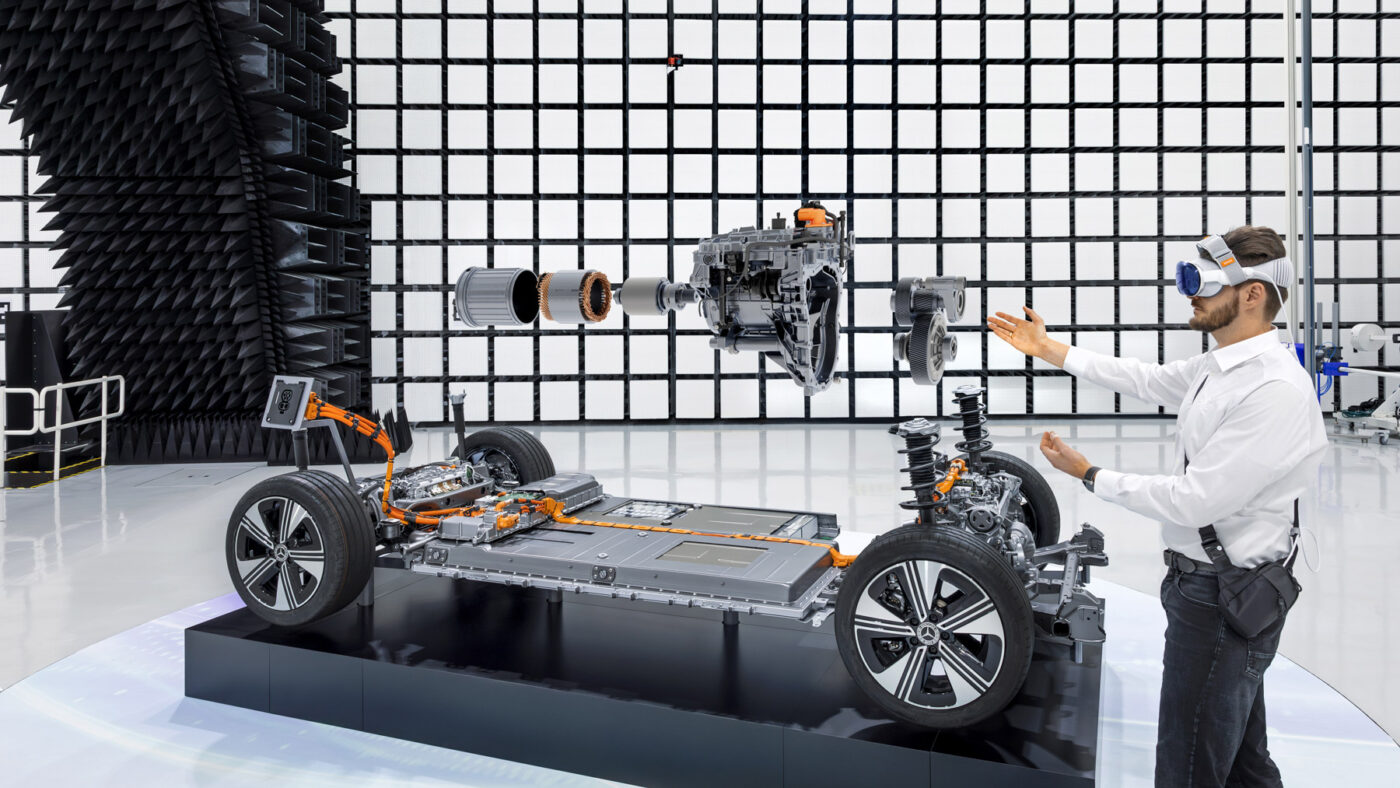

The Electric Software Hub

The new building, where large parts of the development took place, also contributed to the CLA and the MMA. The ESH, as it is known internally at Mercedes, is an interdisciplinary development centre. It is not only working on the name-giving software for electric cars but also merging it with hardware.

The ESH has several floors of office space as well as test benches. It can test individual drive components or the complete electric architecture with all current-carrying components from the small sensor to the electric window regulator to the 800-volt battery under various climatic conditions, and also complete vehicles.

“In the past, each department developed its own components, and in the end, everything was put together – engine, transmission, chassis, chassis and so on. Today, everything has grown together,” said test engineer Philipp Werner. “In the Electric Software Hub, the software is developed on the upper floors, and we have the drive and vehicle test benches on the ground floor. If we discover a problem on the test bench here, our colleagues can be here with a laptop in a matter of minutes.”

Finished prototypes can leave the ‘ESH’ while staying connected to the site via the measurement technology. “If our colleagues notice an anomaly on the road, whether on the Swabian Alb, in the Arctic Circle or in the desert, they can press a button in the vehicle and a flag is added to the data record at that location,” explains Werner. “We can then access this data in real-time and repeat this exact scenario on the test bench until we have solved the problem.”

The engineers also used the test benches at the ESH to prepare a record drive to demonstrate the targeted “time efficiency.” On the test track in Nardò in southern Italy, a pre-series vehicle of the CLA covered a whopping 3,717 kilometres in 24 hours. The journey was planned and monitored from the ESH, but simulations and test bench runs are only part of the job – the hardware and software must also be able to realise this in practice. With a top speed of 210 kph and 40 precisely calculated charging stops, the plan worked.

Indeed, no CLA customer will ever find themselves in the situation of driving over 3,000 kilometres at 210 kph at a stretch. Nevertheless, test engineer Werner sees a practical benefit for the customer: “For example, we went through the usual communication with the charging station at every charging stop, just like every customer does. We were able to save a few seconds in this process.” Or as Torsten Eder, Head of E-Drive Development, put it, looking at the big picture: “The endurance run in Nardò proves that our technologies are also reliable on the road.”

0 Comments