Renesas & Nidec introduce new e-axle system

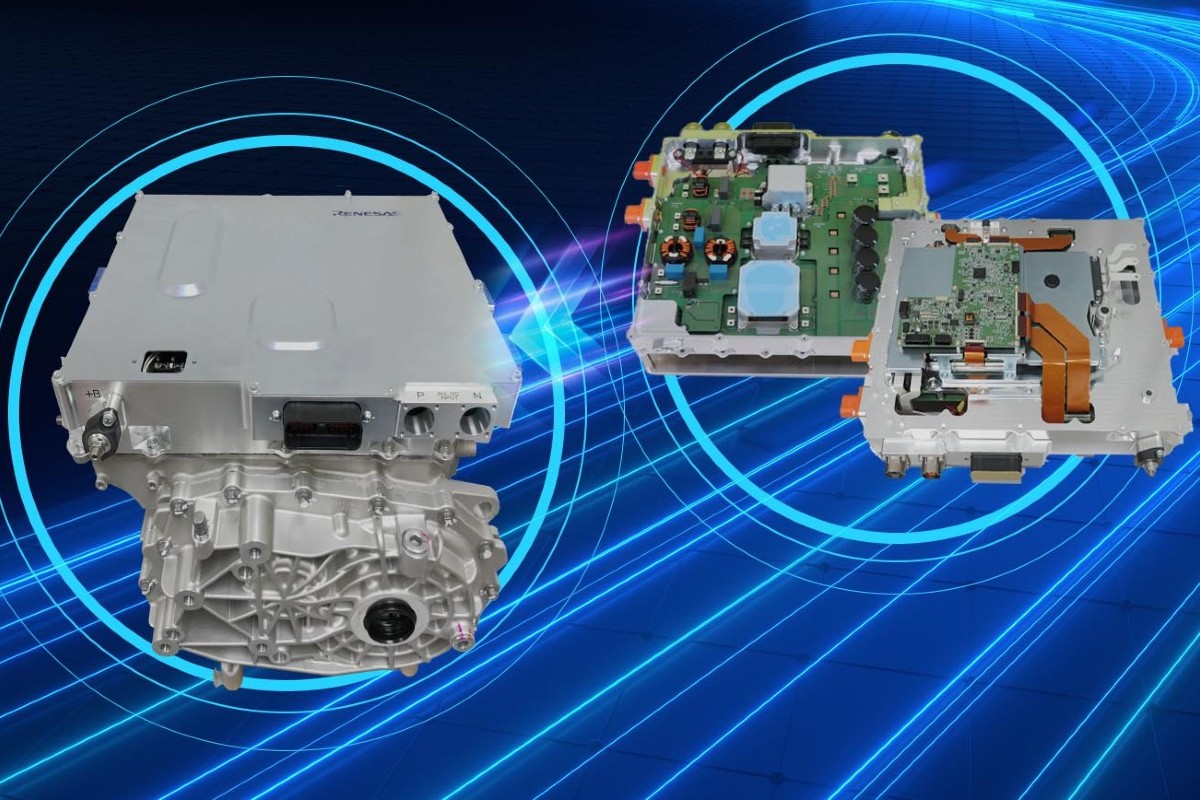

As early as mid-2023, Nidec and Renesas announced their intention to develop an ‘X-in-1’ system that combines the electric motor and power electronics and offers comparatively high performance and efficiency, while being small, lightweight and low cost. They are now presenting their solution as part of a live demonstration at electronica 2024 in Munich. This is a proof of concept and not yet a production-ready device.

Together with the motor and gearbox, the unit houses an inverter with an output power of 70 to 100 kW and a maximum efficiency of 99 per cent, a DC/DC converter with an output of 1.5 kW, a 6.6 kW onboard charger, a power distribution unit, a battery management system and a PTC heating control system. The special feature: The study controls the eight functions with a single microcontroller. “By systematically integrating these functions with a single MCU, the PoC has significantly reduced the number of components, cost and size,” notes Renesas.

“We are thrilled to deliver the world-class 8-in-1 E-Axle solution and have successfully verified its operational performance in collaboration with Nidec,” said Chris Allexandre, Senior Vice President and General Manager of Power at Renesas. “We are committed to delivering a broad range of power management products that work together with our digital products to provide complete, ready-to-use, system-level solutions. This approach enables Renesas to help customers accelerate their development and time to market.”

Based on the proof of concept, Nidec plans to commercialise this new generation of E-Axle systems rapidly. Renesas aims to “deliver turnkey semiconductor solutions for various X-in-1 systems based on the reference design verified through this PoC.” With these solutions, developers can ‘immediately implement and evaluate their X-in-1 systems, accelerating the development of electric vehicles’. Renesas emphasises that it will be able to offer its customers comprehensive system support and software as well as key building blocks for their X-in-1 solutions in the future.

Nidec initially began series production of its second-generation electric axle system in October 2022. The drive solution called Gen.2 has since been produced in Guangzhou, China. The most important features of this 100 kW electric axle (compared to its predecessor with 100 kW) are a 19% lower weight and a 20% higher torque and power density, according to Nidec.

The basic model of Nidec’s e-drive modular system, the 150 kW Ni150Ex, was presented in 2018 – with the Chinese manufacturer GAC as the first customer. In spring 2019, the Japanese company announced variants with 100 and 70 kW power, before the 50 and 200 kW power levels were presented in February 2020. With the range of 50 to 200 kW engine power (or more with two engines in the vehicle), Nidec can cover the vehicle segments A to E, including everything from small cars to the luxury class.

1 Comment