Stellantis aims to improve EV aerodynamics with MGP technology

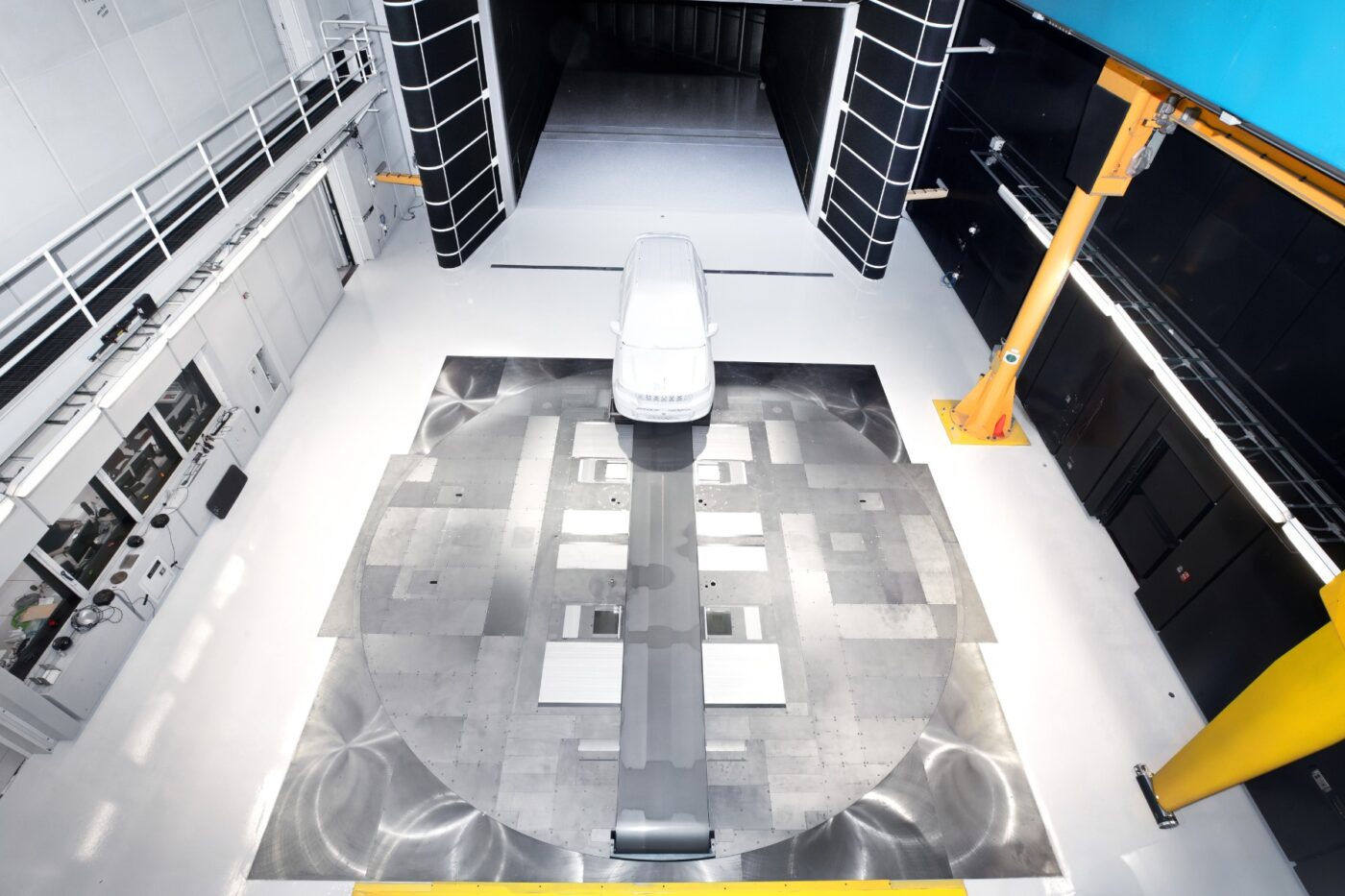

The MGP technology uses high-pressure compressed air to drive the wheel and centre belts at speeds of up to 140 mph (504 kph). Upgrading the aero-acoustic wind tunnel will allow Stellantis to measure and reduce airflow resistance from wheels and tyres. According to Stellantis, airflow resistance makes up ten per cent of total real-world aerodynamic drag. To reduce the latter, the manufacturer hopes to enhance its wind tunnel with the Moving Ground Plane (MGP) technology. It would allow it to design EVs more aerodynamically, so they can offer more range on a single charge.

“Range is a core consideration for customers transitioning to cleaner mobility through battery power,” said Mark Champine, senior vice president and head of North America engineering technical centres. “That’s what makes this investment so critical. By reducing drag, we improve electric-vehicle range and, ultimately, the overall customer driving experience.”

Champine added: “For EVs, a range increase enabled by improved aerodynamics can lead to potential battery-size reductions. This has positive implications from more efficient packaging-to-weight savings that, in the end, will enhance the customer experience.”

The upgrade allows the company to simulate real-world travel with test vehicles. During the simulation, four belts suspended by air cushions achieve wheel movement at all four corners. The simulation employs an additional belt that runs longitudinally beneath the vehicle to replicate on-road travel conditions. Moreover, the wind tunnel also provides a valuable complement to virtual development tools. “This apparatus is a great addition to virtual tools, which may not account for factors such as tyre deformation that can compromise aerodynamics,” said Champine. “With this technology, we can replicate such conditions and capture real-time data to explore solutions.”

The research and technical centre also features vital automation capability, which helps to accelerate the time required to make changes to the wheelbase and track testing.

This investment also aligns with the company’s Dare Forward 2030 strategic plan. Furthermore, the upgraded facility is part of an estimated $85 million investment outlined in the 2019 UAW contract. The investment aims to yield a new annexe for staging test vehicles and an outbuilding to support the MGP system.

1 Comment