Argonne National Laboratory researchers announce new cathode material

The new material is an improved version of a previously developed NMC material. The main difference is that the surface is now enriched with cobalt and the interior is virtually cobalt-free, making better use of the advantageous properties of the active materials. The use of cobalt has also been significantly reduced and the cathode material is now only comprised of about two per cent instead of ten to 20 per cent nickel.

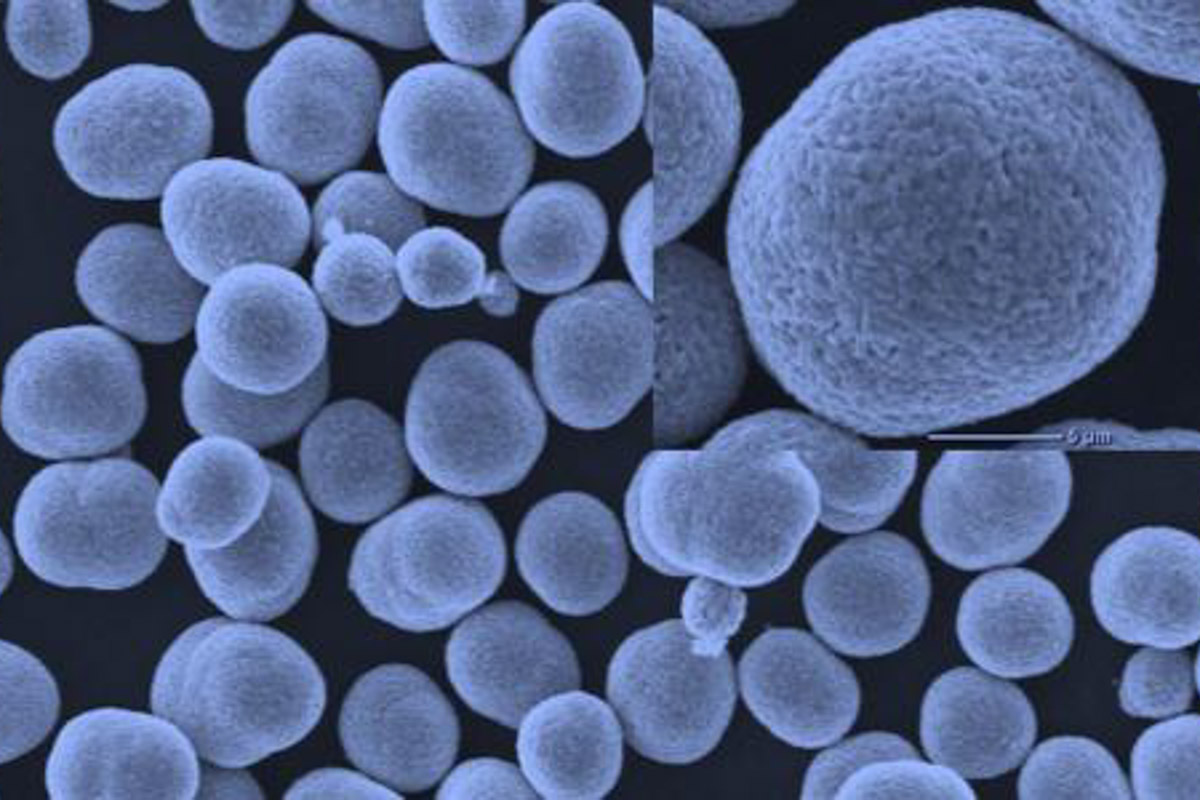

The Argonne researchers had previously optimised the composition of nickel, manganese and cobalt for the original NMC material. In the ‘composition gradient design’, the nickel concentration gradually decreases from the core of the cathode material particles to the surface. “The idea was to maximize energy density at high-voltage battery operation and minimize reactivity,” writes the institute. These cathode particles have a layered structure. These ordered layers of metal atoms create pathways for the transport of lithium ions between the electrodes of a battery.

This material has been licensed to battery and material manufacturers and is therefore used commercially. “For EVs to replace gasoline-powered vehicles on a global scale, batteries must be able to operate at higher voltages to deliver even more energy and longer driving ranges,” said Khalil Amine, head of the Advanced Battery Technology team at Argonne, adding: “At the same time, they must remain safe and cost less to manufacture.”

However, when operating at high voltages, cathode particles with layered, ordered structures tend to break and react more strongly with the battery’s electrolyte. This not only reduces the service life of the battery but can also lead to safety concerns in extreme cases.

The ANE teams have therefore added another special feature to the ‘composition-gradient cathode design’ for further development, namely the cobalt convolution process mentioned at the beginning. This is why the researchers are now also talking about a ‘dual gradient design.’ This also breaks up the ordered, layered material structure: In the core, the particles continue to consist of layered material, but on the surface, the material becomes increasingly disordered.

The idea is that the disordered particle surface should suppress crack formation and reactivity, while the ordered core should maximise ion transport. “In this way, the cathode can potentially achieve high capacity and stability while operating at high voltages,” the institute explained. The tests are said to have confirmed that the production of cathode material with these special properties was successful – and that the particles also remain stable when operated at high voltages. After 500 charging and discharging cycles, the material is said to have lost only two per cent of its capacity.

“We proved that the disordered particle surface is indestructible, with virtually no reactivity or structural strain,” said Tongchao Liu, a chemist at Argonne. Liu is the lead author of the recently published article in Nature Energy on Argonne’s dual-gradient cathode. Collaborating partners include the Department of Energy’s Brookhaven Institute and the Lawrence Berkeley National Laboratory.

0 Comments