ProLogium presents silicon composite anode

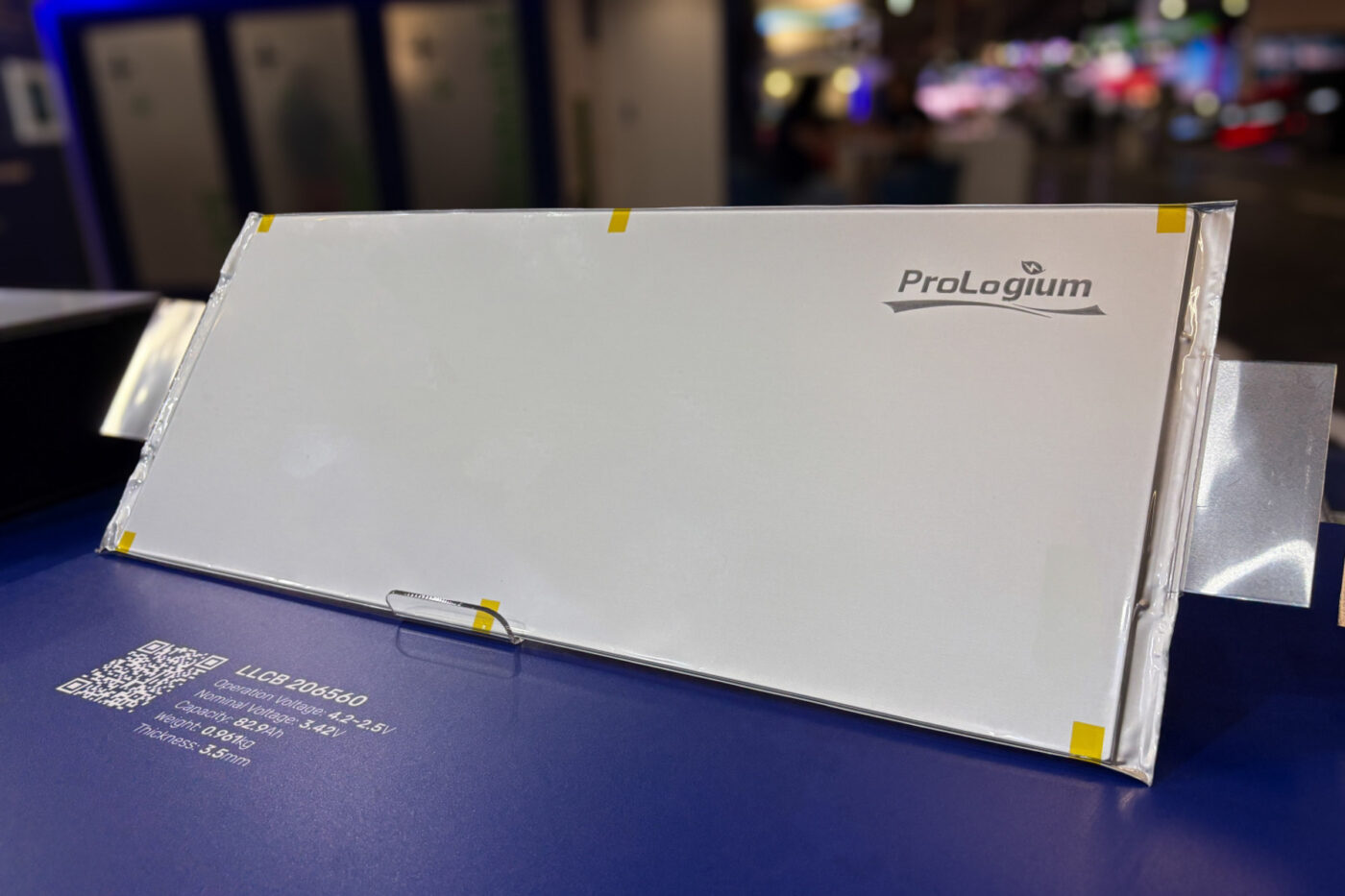

The Taiwanese company specialises in solid-state batteries with ceramic electrolytes and refers to its developments as a ‘lithium-ceramic battery,’ or LCB. ProLogium says that with the new silicon anode, the system has already achieved a volumetric energy density of 749 Wh/l and a gravimetric energy density of 321 Wh/kg. It is expected to reach 823 Wh/l and 355 Wh/kg this year. These figures are at the system level, not the cell level.

To make the development results more credible, ProLogium had the new batteries tested by TÜV Rheinland. “According to TÜV Rheinland test data, the battery charges from 5% to 60% in just 5 minutes and reach 80% in 8.5 minutes, an unmatched achievement in the competitive EV market. This advancement greatly reduces charging time and extends vehicle range, significantly enhancing overall performance,” says ProLogium.

However, the company does not provide any details about the silicon composite anode. Silicon-containing anodes increase the energy density of battery cells and improve their fast-charging capability. However, the material expands and contracts considerably during charging and discharging. This mechanical stress has so far led to a shorter service life. For this reason, anodes with a low silicon content are only used in a few series-produced electric cars; the majority of the active anode material is still graphite. How ProLogium has solved this problem with its pure silicon anode is not explained.

Instead, the Taiwanese company explains its goal: higher energy density is not necessarily intended to enable longer ranges, but smaller and lighter batteries with a similar range. And it gives an example: an electric car with this battery technology should be able to travel the same distance with 55 kWh as with a conventional 83 kWh battery. As the car with the smaller battery is 300 kilograms lighter, fuel consumption is reduced and the range increases. In addition, the smaller battery minimises the CO2 footprint, and the costs are also said to be lower – although this is not quantified. As the battery is capable of fast-charging, ProLogium claims that it can be recharged for a further 300 kilometres in five minutes.

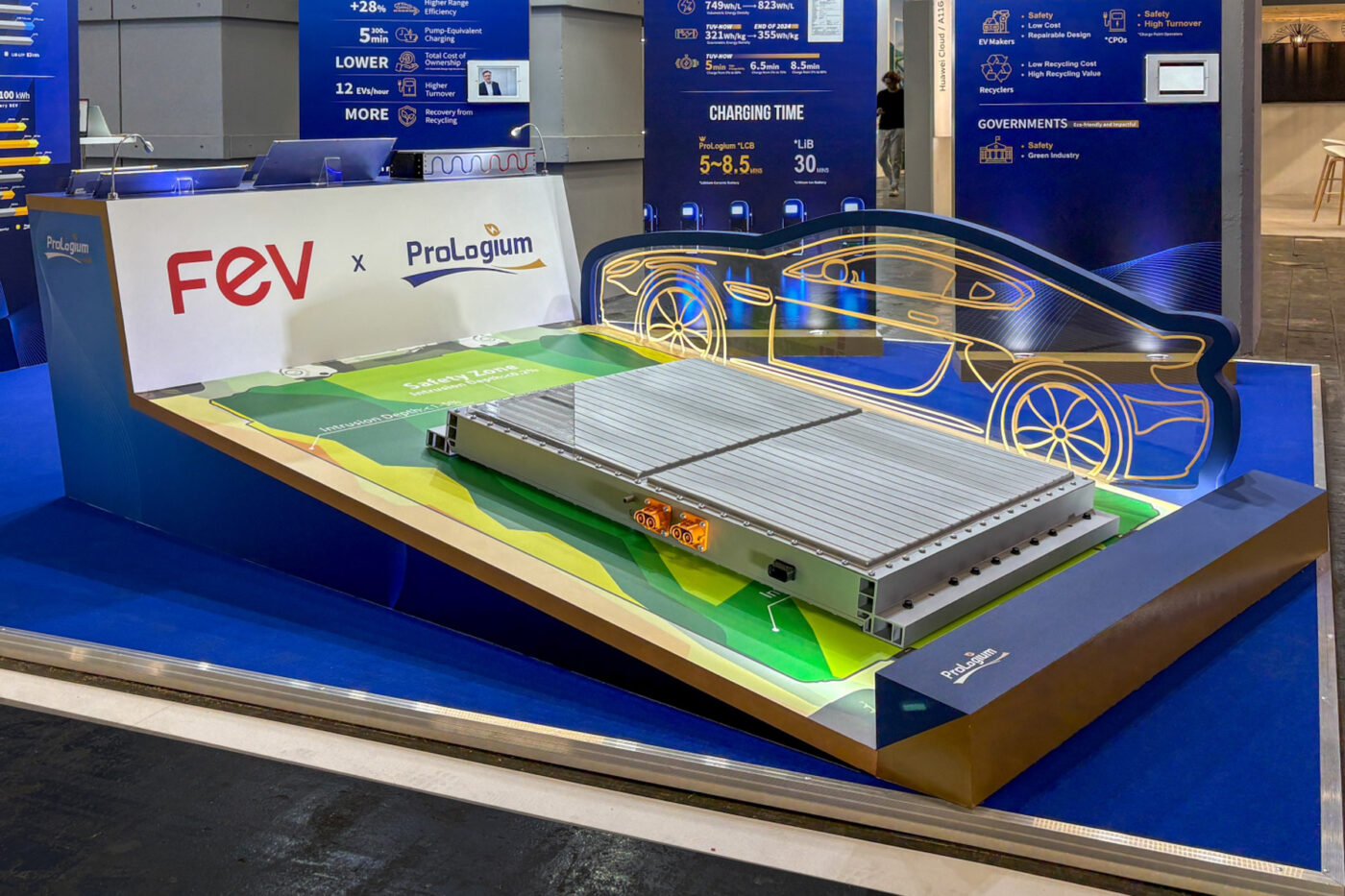

ProLogium has yet to specify when it will launch this technology. According to earlier reports, it should be 2024. However, ProLogium did show in Paris how battery packs can be integrated into electric vehicles. To develop these modules and packs, ProLogium benefited from its partnership with the German FEV Group, which has been in place since 2022. “This collaboration marks ProLogium’s progression from producing EV components to developing battery modules and packs, underscoring the company’s substantial strides in commercialisation,” says ProLogium.

“Due to the significantly increased energy density of the LLCB cell of 321Wh/kg, the energy storage system can be designed to be smaller and lighter for a vehicle with a targeted driving range, thus reducing power and space requirements,” explains Thomas Hülshorst, Global Vice President Electric Powertrain at FEV. “By combining ProLogium’s visionary technology with FEV’s engineering strengths, we are paving the way for the future of sustainable mobility.”

0 Comments