OCSiAl to supply ProLogium with carbon nanotubes for solid-state batteries

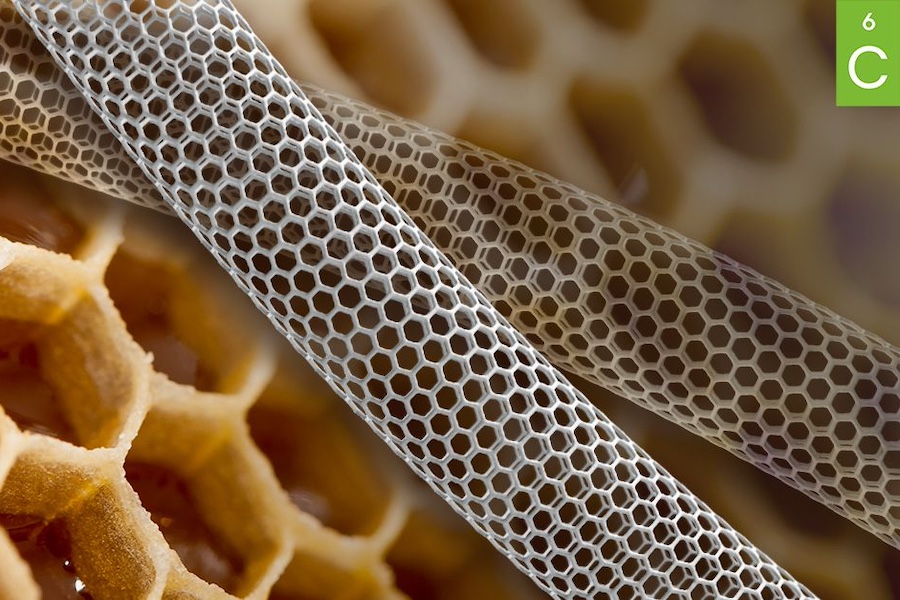

The new production plant for the nanotubes, which resemble a honeycomb structure due to their hexagonal pattern (see image), expands the European supply chain of the Taiwanese company ProLogium. By incorporating OCSiAl’s single-walled carbon nanotubes, ProLogium aims to produce the “world’s most advanced lithium ceramic batteries”.

With an annual capacity of 3,000 tons of nanotube dispersion, the OCSiAl plant will support ProLogium’s Gigafactory project in Dunkirk (Dunkerque), France. The project is due to be completed at the end of 2026 and start mass production of solid state battery cells for electric vehicles in early 2027.

ProLogium specialises in the research, development and production of lithium-ceramic batteries for electric vehicles. The incorporation of OCSiAl’s single-walled carbon nanotubes into the electrode strengthens ProLogium’s technology to deliver advanced batteries, says OSiCAl, which claims to be the world’s largest producer of graphene nanotubes. Nanotubes, explains the company, are “nature’s longest and most flexible material for conductivity and reinforcement of electrodes.”

“ProLogium continues to make breakthroughs in next-generation battery technology. OCSiAl’s cost-effective high-purity single-wall carbon nanotubes further enhance ProLogium’s lithium ceramic batteries, allowing them to achieve even greater energy density and rate capability,” said Vincent Yang, founder and chairman of ProLogium Technology.

OCSiAl says its new facility meets the “highest product quality standards in the industry” and accelerates ProLogium’s ambitions for product excellence and sustainable development in Europe.

“The collaboration between OCSiAl and ProLogium—two leaders in their fields—makes it possible to form a robust supply chain to reduce manufacturers’ carbon footprints and continue driving global innovation toward a fully electric and sustainable future,” said Andrej Seniut, Head of OCSiAl Energy. The next OCSiAl plant is scheduled to go into operation in Luxembourg between 2027 and 2028.

At the beginning of 2024, ProLogium opened its first large factory for the production of lithium batteries with ceramic solid electrolytes in Taoyuan (Taiwan) with an initial annual capacity of 0.5 GWh, which is to be quadrupled to 2 GWh. ProLogium made its plan for a factory in France official in May this year. The Taiwanese manufacturer’s first European factory will be built in the northern French port city of Dunkerque – which is fast becoming a hub for European battery production and recycling. ProLogium will invest 5.2 billion euros to build the 48-GWh factory, which will include a research and development centre. Construction is scheduled to begin in the second half of 2024, and production is expected to start at the end of 2026.

So far, ProLogium produces its solid-state batteries in Taiwan, where the production is only designed for a capacity of 3 GWh. Last year, the Vietnamese automaker VinFast took a stake in the company. In return, ProLogium is to supply solid-state battery cells to VinFast from 2024 onwards. Mercedes-Benz also invested a high double-digit million euro amount in ProLogium in January 2022 and agreed to jointly develop next-generation battery cells with the Taiwanese company.

In the summer of 2023, the French government received the go-ahead from the EU Commission to subsidise research and development of solid-state batteries for electric vehicles with ProLogium. The European Commission approved funding of €1.5 billion under EU state aid rules for the R&D project called “Prometheus”, which will run until the end of 2029.

0 Comments