EMR opens EV battery recycling facility in Birmingham

The new battery recycling facility in Birmingham, West Midlands, England, is EMR’s second of this kind, after the company’s site in Hamburg, Germany, which is operated jointly with Northvolt, with its Nordic battery industrial ecosystem.

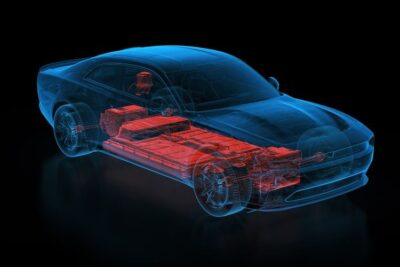

The recycling specialist EMR has said that the new electric vehicle battery recycling facility will have the capacity to test batteries to establish whether they should be repaired, reused – in second-life applications such as other vehicles or stationary storage systems – or recycled.

When batteries enter the system at the EMR facility, they will initially be sourced via product recalls, warranty failures, and end-of-life e-bikes and e-scooters. The first step in any repair or reuse is to first assess the state of the battery and whether it can be repaired, to go on to its best first life, and whether it can be reused for applications such as stationary storage systems, for example, to stabilize electricity grids, or, whether the battery needs to be recycled to extract valuable raw materials to go back into making new batteries.

For the latter process, EMR has not said where the batteries for recycling go after they have been tested, discharged and dismantled. In their German facility, the British company is cooperating with Northvolt – here, after battery modules have been recovered from the packs, they will go to Northvolt’s recycling facilities and be crushed to recover plastics, aluminium and copper. The remaining material, known as ‘black mass’, is processed at Revolt Ett using Northvolt’s Hydromet technology to recover actual battery materials such as lithium, nickel, manganese and cobalt.

While it is early days in the EV battery recycling business, regular traction batteries from cars can be dismantled and the contents recycled, and batteries that have never been used or already superseded are currently filling second-life applications for stationary storage, for example, to stabilize grids.

Helen Waters, head of electric battery recycling at EMR, explained that the recycling centre comes after more than four years of research alongside EMR’s partners in their RECOVAS initiative, and two years of development at the site.

EMR Recycling led the RECOVAS project to create a new circular end-of-life supply chain for EV batteries. Along with EMR, RECOVAS included Bentley Motors, BMW, Jaguar Land Rover, the University of Warwick, the Health and Safety Executive, the UK Battery Industrialisation Centre, Autocraft Solutions Group, Connected Energy — which repurposes electric car batteries — and uRecycle.

Waters revealed that EMR uses “market-leading systems” and software to re-risk the process of discharging the cells prior to recycling. “Our high-voltage testing team is led by former Jaguar Land Rover EV battery technician Sanjay Kundu.”

Since high-performance electric vehicle batteries (such as in cars, vans, trucks and buses) have a first life of between 8-10 years, it will be some time before there is a significant quantity of batteries ready for reuse (in slower electric vehicles or stationary storage) recycling. In the meantime, according to similar companies in Europe, there will still be plenty of work to do on faulty, defunct or superseded batteries, from, for example, unsold EVs, all of which can be either repaired, reused or recycled.

Waters explained, “While the transition to EVs is now speeding up, it will be 10 to 15 years before they arrive at EMR facilities in anything like the same quantities that petrol-powered vehicles do today. The opening of this new facility at EMR Birmingham is further proof that EMR is solving tomorrow’s challenges today.”

Source: information via email, see also emrgroup.com

0 Comments