Hyundai reportedly plans battery cell pilot production

According to a recent report by The Korea Economic Daily, the Hyundai Motor Group is preparing to build its first production lines for battery cells. Informants familiar with the matter told the newspaper that this is the first step in advancing battery technology internally to improve both the performance and cost of its electric models.

The company could initially set up production lines with a 1-2 GWh capacity for prototypes at its research and development centre in Anseong, Gyeonggi Province. Hyundai will likely focus on ‘ternary’ batteries such as nickel-cobalt-manganese (NCM). Rumours about Hyundai’s own battery cells were already reported in November 2023, but there was talk of LFP cells at that time.

However, things are getting more concrete this time: negotiations with suppliers to provide the battery materials have been underway since the second quarter. Hyundai is allegedly talking to South Korean suppliers such as LG Chem, as well as Chinese companies. According to The Korea Economic Daily, negotiations concern the quantity and price of the cathodes, which will be delivered from around 2027.

However, Hyundai’s battery production plans are not set in stone. The manufacturer could stick with pilot production to validate the self-developed cells on a certain production scale. The report states that Hyundai is looking to outsource “the production of batteries it designs to SK On and other battery cell makers under original equipment manufacturing contracts, instead of manufacturing them at its production lines.”

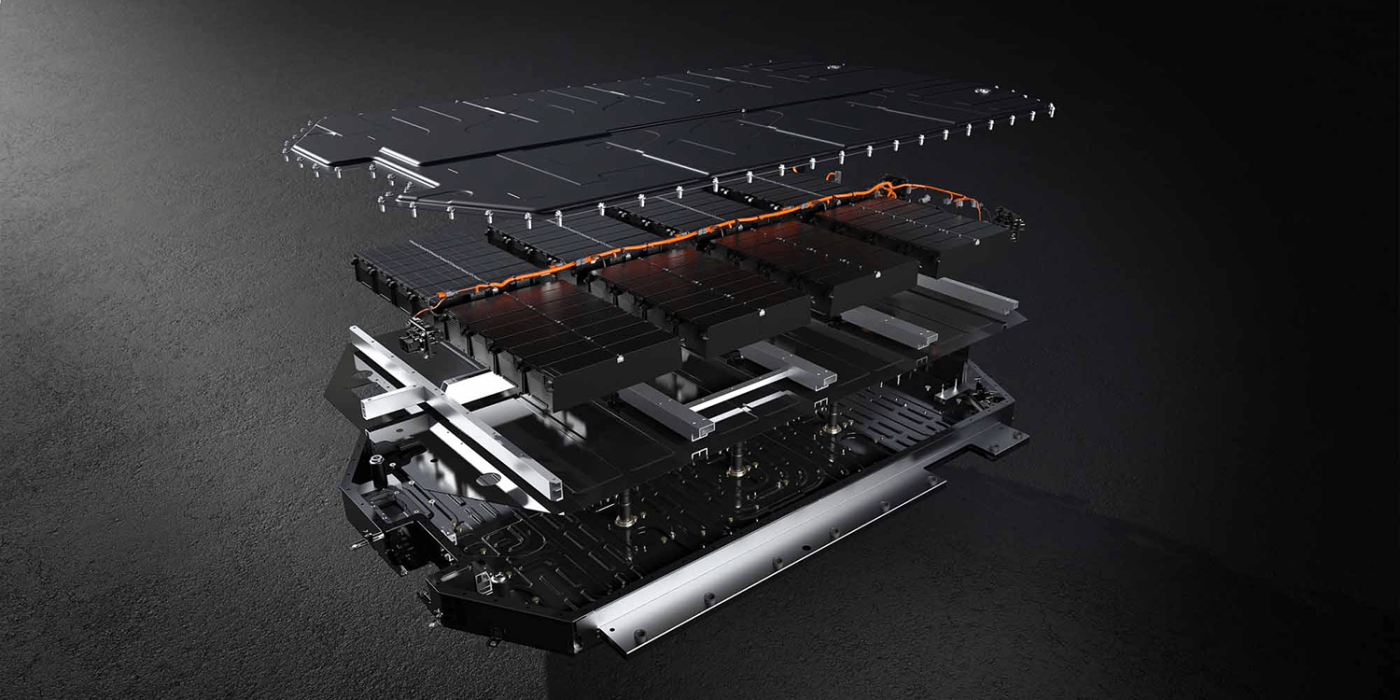

The Group’s Hyundai, Kia, and Genesis brands currently purchase their battery cells from SK On and LG Energy Solution in South Korea and, in some models, from Chinese market leader CATL. In October 2023, Hyundai also ordered cells from Samsung SDI for the first time—the prismatic cells with NCA chemistry will be used in Europe from 2026. Exide will provide LFP cells for EVs manufactured in India.

1 Comment