Georgia Tech reveals iron-chloride cathode for solid-state batteries

The chemistry used in the newly developed cathode – called FeCl3 – uses abundant materials iron (Fe) and chlorine (Cl), avoiding the use of nickel and cobalt. The team’s initial tests showed FeCl3 performed as well or better than other more expensive cathodes, with a higher operational voltage as LFP batteries now flooding the market.

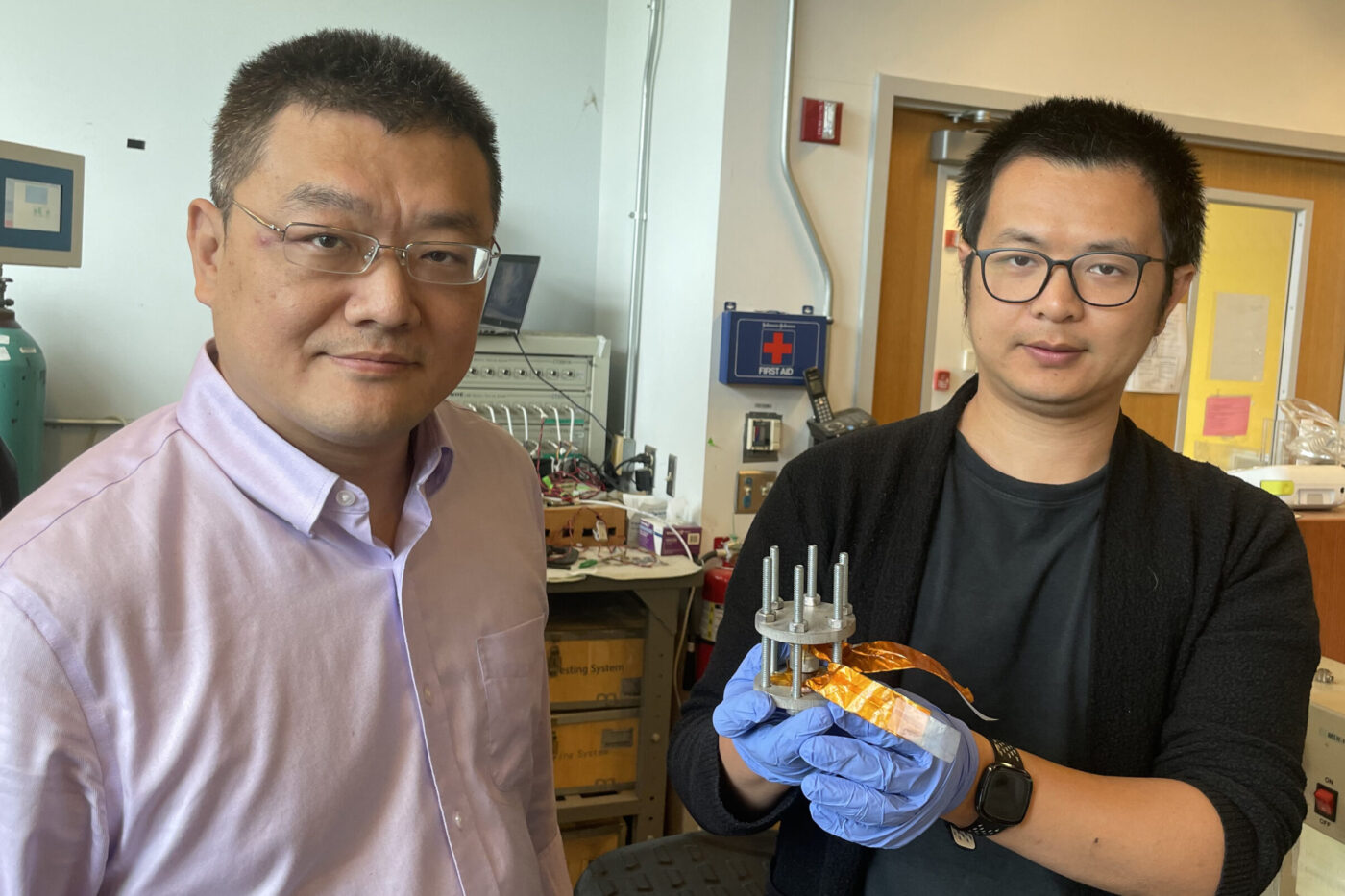

“This could not only make EVs much cheaper than internal combustion cars, but it provides a new and promising form of large-scale energy storage, enhancing the resilience of the electrical grid,” says lead researcher and associate professor Chen. “In addition, our cathode would greatly improve the sustainability and supply chain stability of the EV market.”

The researchers estimate that this technology may need less than five years before it reaches commercial viability in electric vehicles. To get there, Chen says, “We want to make the materials as perfect as possible in the lab and understand the underlying functioning mechanisms.” He adds, “But we are open to opportunities to scale up the technology and push it toward commercial applications.”

Potentially significant for both electric vehicles and large-scale energy storage systems, the research group’s findings were published in the paper “Low-cost iron trichloride cathode for all-solid-state lithium-ion batteries” in the publication Nature Sustainability.

3 Comments