Protean’s newest generation completes drive system validation

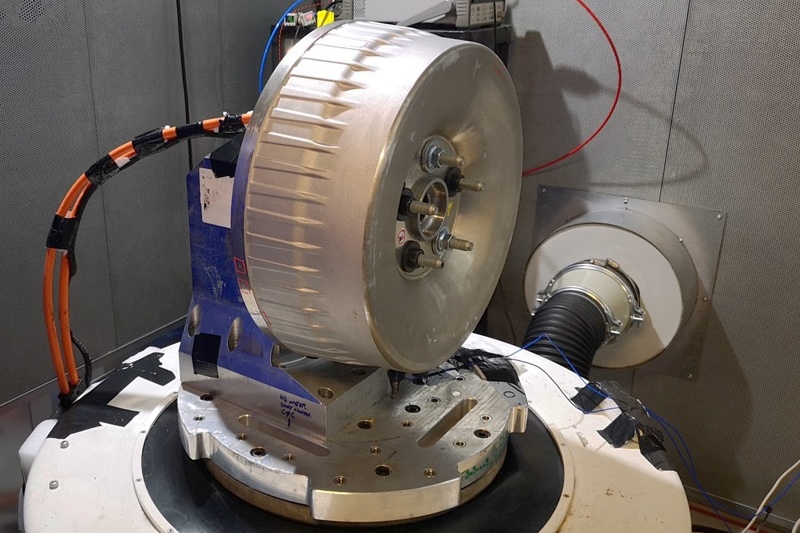

The 5th generation ProteanDrive (Pd18 Gen5) delivers a peak torque of 1500 Nm, which Protean Electric says sets a new industry standard for the performance of a wheel motor system that fits into an 18-inch wheel with an integrated inverter.

Protean Electric writes that it designed the in-wheel motor (IWM) in a modular configuration, allowing for faster development of new product variations at lower risk. According to the manufacturer, this includes offering integrated and detached inverters, with 400Vdc lead products available now, with 800Vdc products by the end of 2024.

“In-wheel motors are proving to be a pivotal, enabling technology for the next generation of EVs. However, much like the first EVs, there needs to be a testing and validation rulebook set out,” said Stephen Lambert, Chief Technology Officer of Protean Electric on the topic of their industry achievement, adding: “As an industry, much has been discussed about the design and validation challenges of in-wheel motors, particularly the demands of reliability and durability due to the harshest installation environments. Looking to the future, our team has invested heavily in our test and validation procedures to ensure that the Gen 5 IWM, exposed to severe shock, vibration, thermal cycle, sand, dust, water, and chemical contamination, is designed to last and do the distance, securing a net-zero future across multiple vehicles and transport solutions.”

Protean last headlines last year when the UK’s Advanced Propulsion Centre allocated eleven million pounds to twelve automotive projects, including one for Protean to develop “lightweight and novel In-Wheel Motors” for OEMs. In 2021, the company was sold by its previous owner, the Swedish NEVS (National Electric Vehicle Sweden), and went to its current owner Bedeo.

0 Comments