US researchers develop thin solid electrolyte

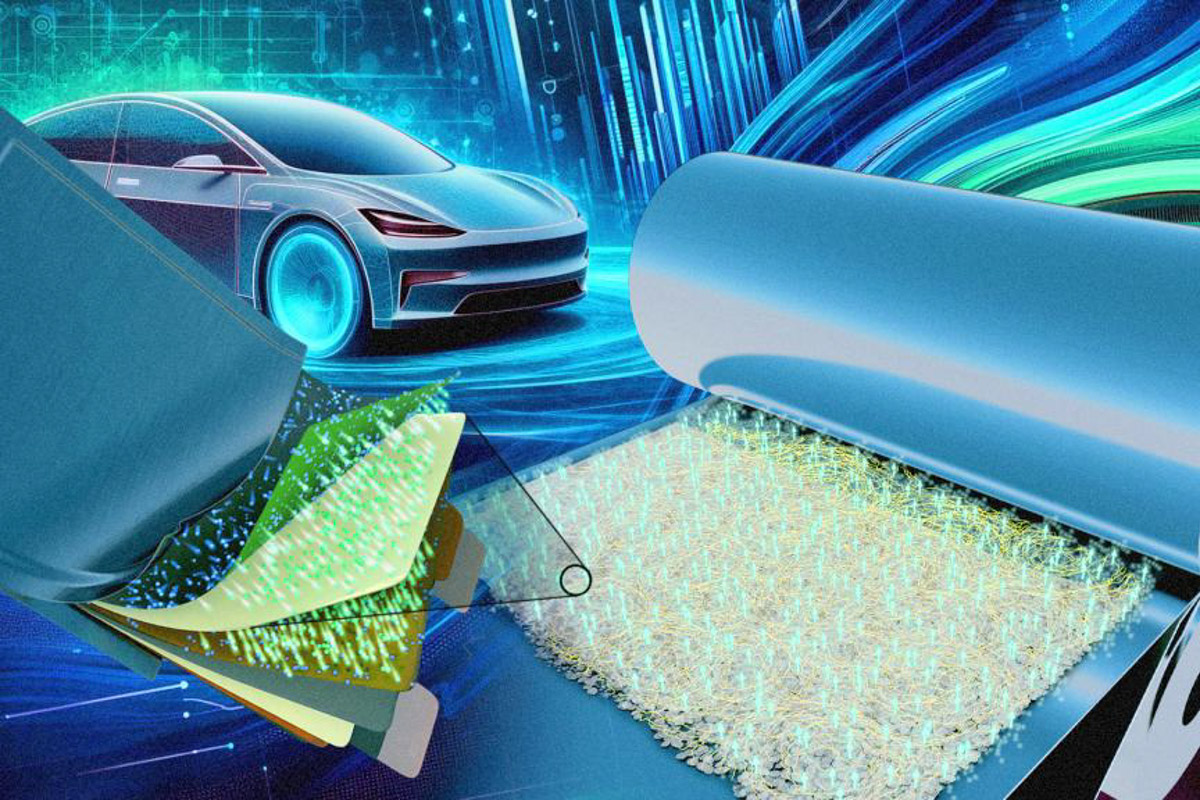

The team at Oak Ridge National Laboratory (ORNL) has built on their previous studies for this most recent research project, the results of which are now published ACS Energy Letters. The polymer binder used previously has now been optimized for use with sulfide solid-state electrolytes. The study aimed to determine the best possible film thickness – to optimise both ionic conduction and structural strength.

Current solid-state electrolytes use a plastic polymer that conducts ions but their conductivity is much lower than that of liquid electrolytes. For this reason, liquid electrolytes are sometimes added to polymer electrolytes to improve conductivity, referred to as semi-solid electrolytes or semi-solid-state cells. ORNL is focusing on all-solid-state technology to exploit the full potential of solid-state cells, for example in terms of safety, if the flammable liquid electrolyte is omitted.

The sulphide solid electrolyte used by ORNL has an ionic conductivity comparable to that of the liquid electrolyte. “It’s very appealing,” says Guang Yang from ORNL. “The sulfide compounds create a conducting path that allows lithium to move back and forth during the charge/discharge process.”

The researchers discovered that the molecular weight of the polymer binder is critical to making durable solid-state electrolyte films. Films made from lightweight binders with shorter polymer chains do not have the strength needed to stay in contact with the electrolyte material. Films made from heavier binders with longer polymer chains, on the other hand, have a higher structural integrity. In addition, less long-chain binder is required to produce a good ion-conducting film. The goal of the study, reveals ORNL, was to find the “Goldilocks” spot i.e.: not too thick, not too thin but just right for supporting both ion conduction and structural strength.

“We want to minimize the polymer binder because it does not conduct ions,” Yang said. “The binder’s only function is to lock the electrolyte particles into the film. Using more binder improves the film’s quality but reduces ion conduction. Conversely, using less binder enhances ion conduction but compromises film quality.“

Various investigations, from electrochemical impedance spectroscopy to scanning electron microscopy and X-ray spectroscopy, were used to improve the polymer film and conductivity. “By understanding these details, we were able to enhance the electrolyte’s ability to conduct ions effectively and maintain its stability,” Yang said. “This detailed analysis is vital for developing more reliable and efficient solid-state batteries.”

Now, the energy density should be doubled to “at least 500 watt-hours per kilogram”, according to the researcher. The cells should be able to increase the energy density in electric vehicles, but also in laptops or smartphones (and therefore the duration of use between two charging processes).

1 Comment