LGES plans dry electrode pilot line before the end of 2024

According to the Korea Herald, LG Energy Solution’s approach is characterized by its flexibility. The LGES method can be used to produce both the cathode and the anode, while other methods use either the anode or the cathode. The LGES method is “independent of the particle size of the materials used”.

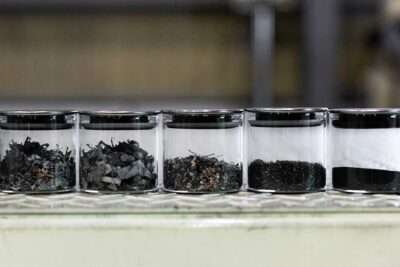

Up to now, battery electrodes have mainly been produced using the wet process: The active materials – in the case of the cathode, for example, lithium, nickel, manganese and cobalt; in the case of the anode, graphite and/or, more rarely, silicon) are mixed in powder form and mixed with organic solvents to form a paste. This paste, known as ‘slurry’ in technical jargon, is then applied as thinly as possible to the carrier foil – the cathode is usually an aluminium foil, while copper foils are often used for the anode. The coated foil is then dried again in large ovens at up to 200 degrees Celsius in order to remove the solvent and obtain the actual electrode material.

These ovens, some of which are up to 100 meters long, not only require an enormous amount of energy to reach the necessary temperatures. As the coated films are extremely sensitive in this work step and must not be contaminated under any circumstances, all these work steps take place in clean rooms – which in turn require energy to clean the air and ensure constant temperature and humidity conditions. If the large ovens are no longer required for dry electrodes, which are coated directly in powder form, the cleanrooms can also be significantly smaller.

Up to 30 per cent lower manufacturing costs

Although the raw materials required account for a large proportion of the battery costs, the energy costs are not negligible. LGES estimates that the dry electrode process could reduce battery manufacturing costs by 17 to 30 per cent. Added to this is the lower energy consumption, which is responsible for part of the CO2 footprint of battery production.

It is not yet known how many dry electrodes LGES intends to produce on the pilot line. However, according to the report, the company is on schedule to complete the plant in Ochang by the end of the year. Ochang is the plant for the production of cylindrical cells, and the series production of the 4680 cylindrical cells is due to start here in August.

LGES has also announced that it is entering the battery diagnostic software business. The software should detect battery defects with an accuracy of over 90 per cent. “Until now, most battery diagnostic software solutions were based on technologies developed by predicting virtual conditions, which resulted in low accuracy when used in real environments,” the South Korean company wrote.

Since the company owns over 8,000 patents related to battery management and has dismantled and analyzed more than 130,000 battery cells and 1,000 modules over the years, the accuracy of its own solution is said to be significantly higher. Among the battery defects to be detected, LG Energy Solution includes voltage drop during charging, battery tab faults, internal micro-shorts, abnormal degradation, abnormal discharge, deviation of specific cell capacity and excessive lithium precipitation.

In addition to a safety diagnostic function, LG Energy Solution has developed a technology that precisely diagnoses and predicts battery degradation. Here too, the company’s know-how should help to reduce the failure rate – LGES speaks of a failure rate of one per cent in battery degradation diagnostics. “We will continue to provide irreplaceable and differentiated customer value, not only in battery manufacturing but also in the field of BMS solutions to ensure the highest levels of safety and performance,” says David Kim, CEO of LG Energy Solution.

0 Comments