SES reports progress with lithium metal battery

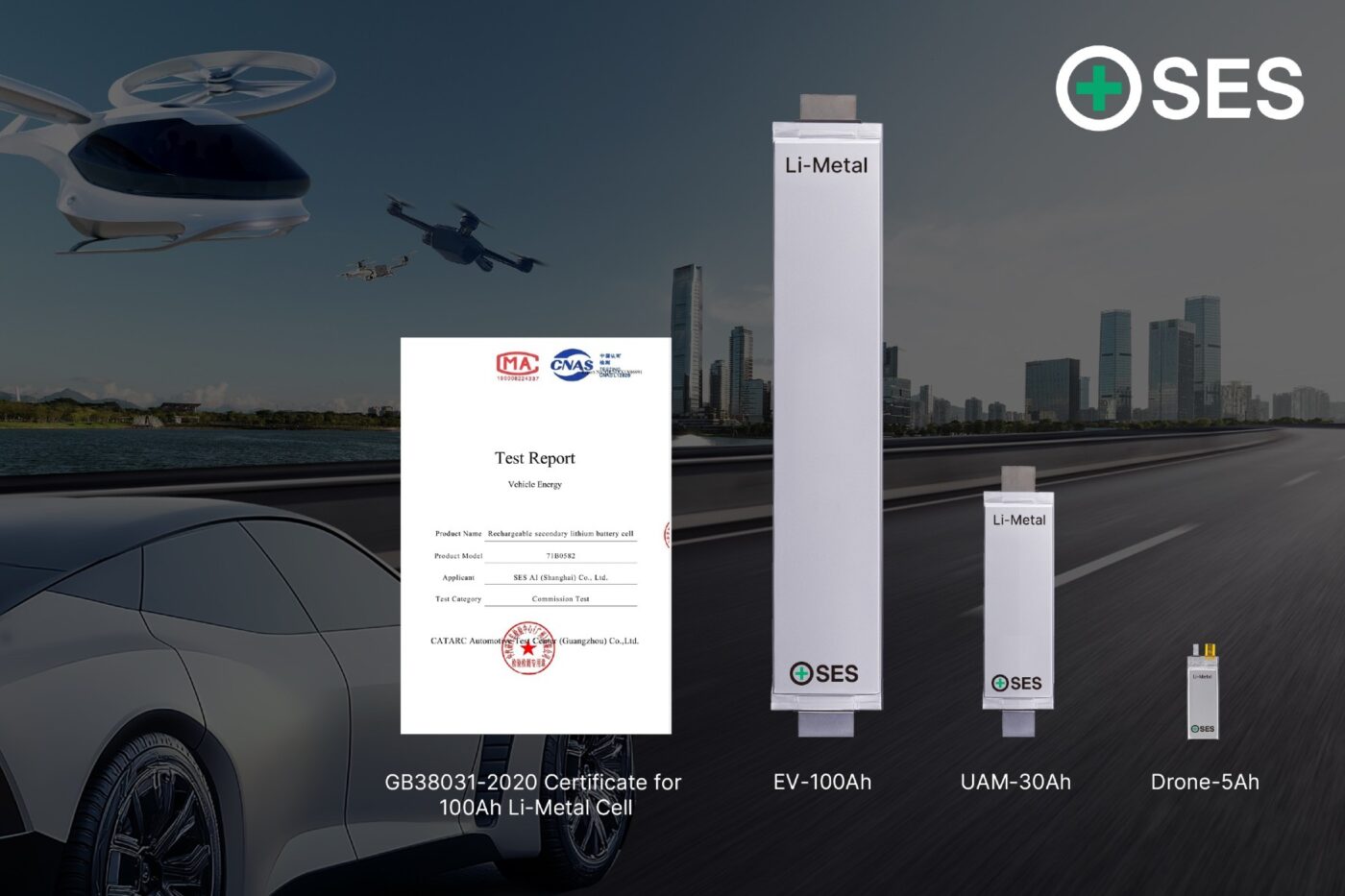

According to SES AI (formerly SolidEnergy Systems), the standard includes a series of strict tests – such as overcharge, over discharge, heating, temperature cycling, and crushing. “Compliance with GB38031-2020 demonstrates that SES AI’s 100 Ah Li-Metal cells can effectively manage safety risks under these stringent test conditions,” the company states, specifying that there are two types of safety tests that Li metal cells for electric car and electric aircraft applications in China must pass. Firstly, abuse is simulated and secondly, “in-use.”

“For abuse tests, passing GB38031-2020 is a key milestone, it’s also the first time in the industry that a high energy density cell such as Li-Metal passes the rigorous safety tests of GB38031-2020,” says Qichao Hu, founder and CEO of SES AI. Regarding operational safety, the deployed safety AI can predict and prevent almost 100% of all incidents in the field. “The results are highly encouraging, affirming our decade-long commitment to refining Li-Metal chemistry and enhancing the safety of Li-Metal batteries,” he adds.

Founded in 2012, SES AI is headquartered in Boston and has offices in Singapore, Shanghai and Seoul. The company’s battery cell is based on a lithium metal anode with high energy density, a protective anode coating and a “proprietary, highly concentrated solvent-in-salt liquid electrolyte.” In July 2021, Qichao Hu stated that the battery should have an energy density of 400 Wh/kg at the cell level. Well-known investors and development partners are General Motors, Hyundai-Kia and Honda.

The next phase of the development partnership (‘JDA’) was also launched with Hyundai at the beginning of this year. That makes SES the only company for Li-metal batteries with ongoing agreements for the development of B-models for the automotive industry. In addition to the electric car market, the company also wants to address electric aircraft manufacturers. Against this backdrop, SES has announced the first production plant for 30 Ah Li-metal cells for urban air mobility. It will be located in Chungju, South Korea.

businesswire.com, investors.ses.ai,investors.ses.ai (Production in South Korea)

0 Comments