Fraunhofer ISI analyses European battery recycling

The Fraunhofer ISIS expects that the recycling of lithium-ion batteries will play a central role in Europe in the future. Currently, both expansion projects and announcements of new recycling plants can be observed across the continent.

In a recent press release, the Fraunhofer ISI has provided an update on the latest developments including, for example, an interactive map showing the battery recycling plants with corresponding capacities in Europe that are expected to be installed by the end of 2024. Battery projects announced for the coming years are also included, as well as their operators. The Fraunhofer notes: “The particularly high number of recycling sites in Central Europe is striking. However, more capacities are also being announced in Eastern Europe.”

The study found that one of the main drivers for the locations of recycling facilities is, logically, “proximity to battery material producers, battery cell producers or car manufacturers.” For this reason, there is a concentration in central and eastern Germany, Hungary, northern France or on the Scandinavian coast. These projects range from small pilot projects to scaling plants with planned expansion stages, such as from Northvolt or EcoBat, even if some of these projects are currently looking uncertain.

Under the analysis, recycling facilities were divided into “spokes” and “hubs,” depending on their recycling depth, referring to he input and output materials of the process. As the researchers explain, “The first steps of battery recycling, known as pre-treatment, take place mainly in the spokes.” At this stage, batteries are collected, discharged, dismantled and turned into “black mass”, a mixture of cathode and anode active materials, which is then further refined to get at the raw materials. Some facilities are even capable of fulfilling both “spoke” and “hub” tasks.

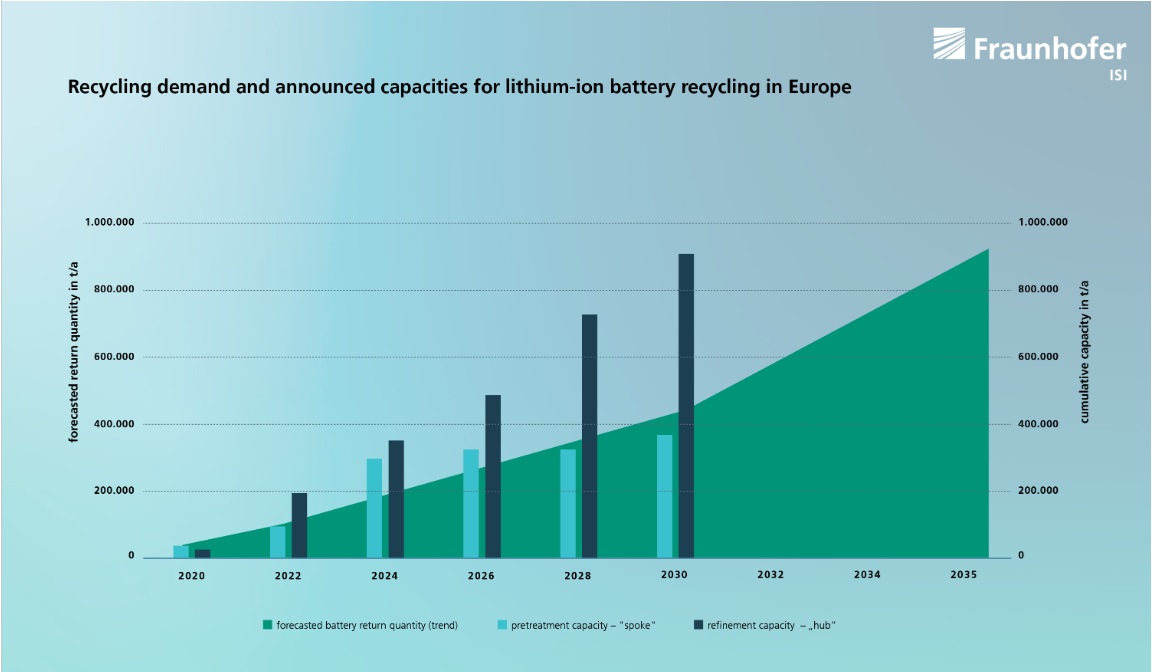

The cumulative capacities of the hubs in Europe currently is estimated at 350,000 tonnes per year, and exceeds the spoke capacities, which are currently estimated at 300,000 tonnes annually. The researchers also found that “Almost every player in European battery recycling is planning to set up several sites for its recycling activities.” By the end of this year, the LIB recycling capacities in the spoke facilities are expected to reach 300,000 tonnes, which is nearly double that of the previous year. Beyond that, “capacities in Europe are expected to reach 330,000 t/a in 2026. By 2030, almost 370.000 t/a in pretreatment capacity has been announced.”

The Fraunhofer study concludes that “the construction and expansion of recycling plants for LIB recycling is currently developing very dynamically and strong growth in both the required capacities and the number of plants can also be expected in the coming years.” This is reflected both by bigger players increasing their capacities, as well as smaller projects growing in number.

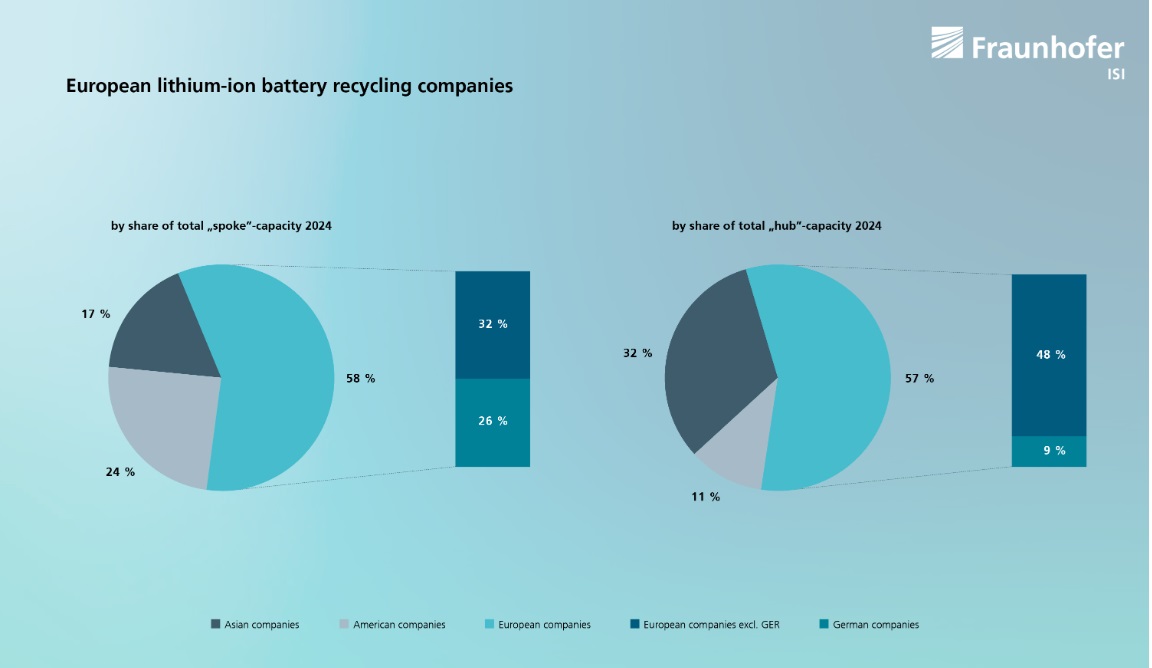

The report also mentions that while Europe is ramping up quickly, “Asian players are catching up.” This refers to companies activities in Europe, as currently “around 40 per cent of spoke capacities in Europe are provided by Asian and American companies.” These are led by SungEel from South Korea, and Ecobat from the USA. Interestingly, this is also spread unequally in the hub and spoke facilities, for which “around a quarter of European spoke capacities come from German companies,” while “Asian and American companies account for around 45 percent of total [hub] capacity.”

0 Comments