Farasis achieves technical breakthrough for ‘million-mile’ battery

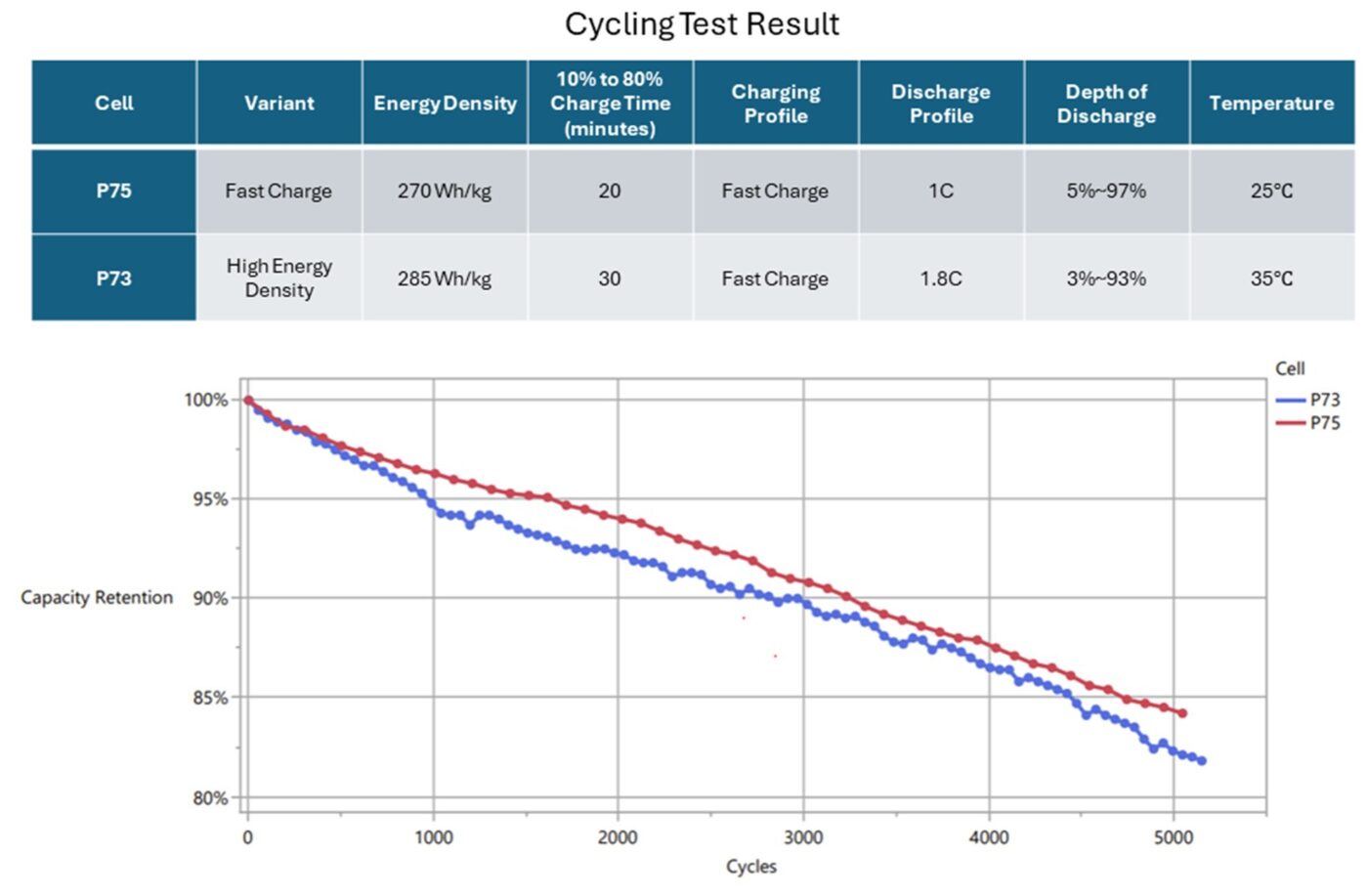

Farasis asserts that achieving the technical basis “for a million-mile battery requires cycling the cell over 5000 times”, a process which the manufacturer states takes somewhere between 24 and 36 months of accelerated testing. Farasis Energy has thus extensively tested its NCM chemistry cells P75 and P73 to evaluate their cyclic and calendar ageing characteristics. These battery cells have been under development since 2018.

The battery manufacturer is quite proud of its testing capabilities, which offer an improved degree of safety and reliability for the technology. As Farasis writes, “cells perform well under industry-standard test conditions (25℃ and C/3 rate), but real-life conditions are rarely ideal.”

Thus the testing process centres around fast charging, charging a battery “from 10% to 80% in around 20 minutes for P75 and around 30 minutes for P73, and a high depth of discharge of 90% and above.” Additionally, the tests were conducted at varying temperatures between 25° and 35°C, which Farasis deems representative of major automotive markets like the USA, Western Europe, and China.

Farasis’s battery cells have now achieved a high energy density, 20 to 30-minute fast charging, as well thermal propagation mitigation. Farasis is currently manufacturing the cells for high-end passenger cars such as Voyah and Mercedes-Benz.

Passenger vehicles is not the only area where Farasis is looking to employ its battery cells. As only about 1% of consumer vehicles reach 200,000 miles, this kind of reliability is not really necessary there, however commercial vehicles such as trucks and buses are more likely to see that kind of daily use. A strategic partnership to develop cells for such vehicles is already underway with FAW in China. Farasis has even worked with players in the electric vehicle takeoff and landing (eVToL) market, who “have independently evaluated these cells, finding them to last over 10,000 flight cycles.”

0 Comments