NEFTON project: Plug in, charge megawatts

The NEFTON project has been looking into various charging scenarios for heavy-duty electric trucks based on the Megawatt Charging System (MCS) for the past three years. The consortium led by the Technical University of Munich concentrates on charging capacities of up to three megawatts. The abbreviation NEFTON stands for the German acronym ‘Nutzfahrzeugelektrifizierung für Transportsektor-optimierte Netzanbindung,’ which means ‘Commercial vehicle electrification for transport sector-optimised grid connection.” ‘In simpler terms, the initiators are looking for solutions to recharge the truck battery at the charging station as quickly as possible.

In addition to the TU Munich, the partners involved in NEFTON are MAN Truck & Bus, AVL Software and Functions, Prettl Electronics, the Forschungsstelle für Energiewirtschaft e.V. and the Deggendorf Institute of Technology. The project is funded by the German Federal Ministry of Economics.

We spoke to Max Zähringer from the Technical University of Munich about how his team designed the charging solution from scratch, whether he sometimes feels caught up in the rapid market dynamics and what role research plays in the drive revolution. He said the demonstration is an exciting event: “1,000 kW is simply not routine.”

***

Mr Zähringer, on 19 July, you and your NEFTON project partners will demonstrate a charging process with over 1,000 kW on the MAN eTruck. How often did you rehearse this in advance?

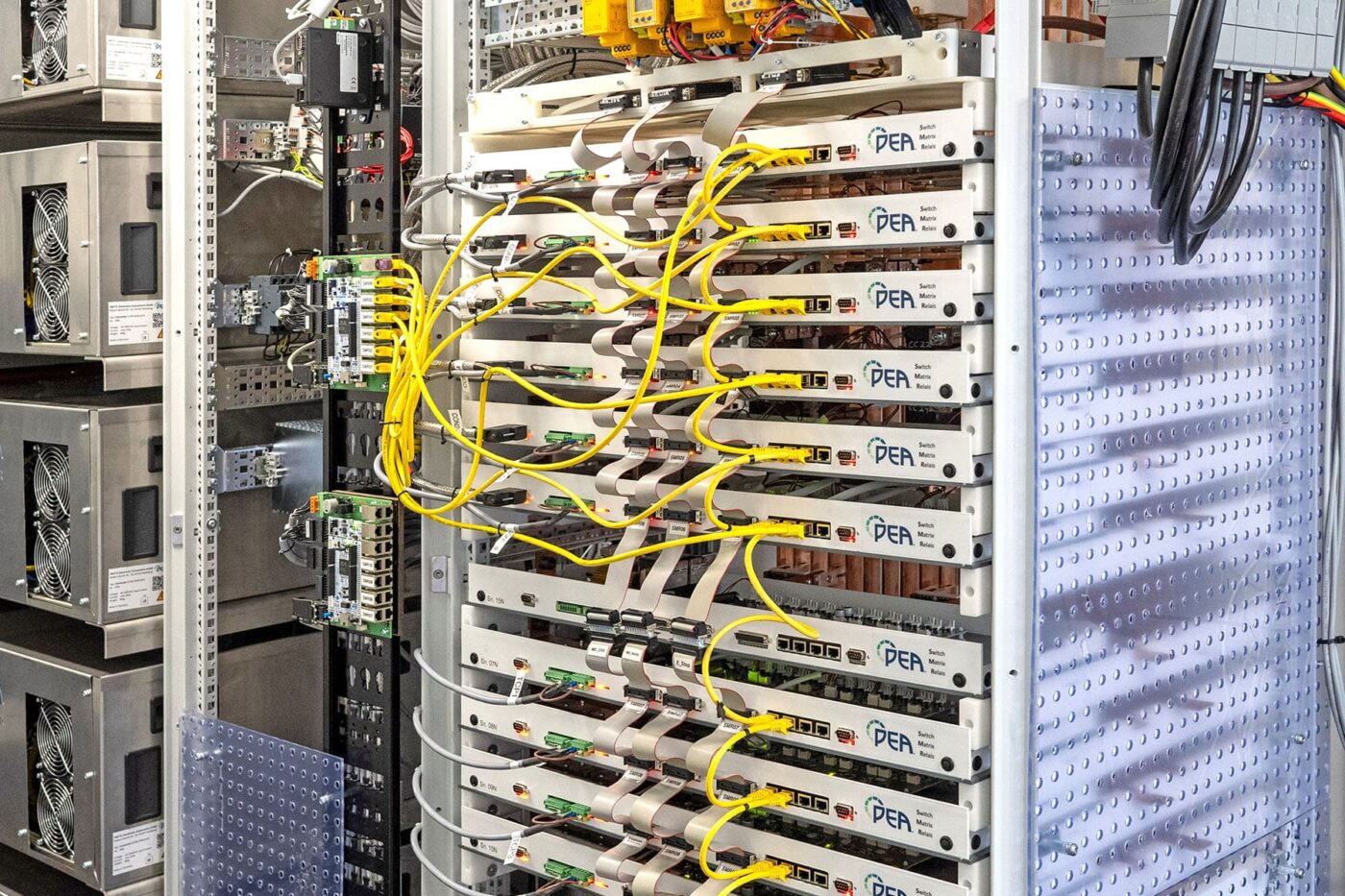

We made the most of the time and really worked until just before the event. Our research charging station brings together a large number of stakeholders and specialist departments. The power electronics have to work, as does the communication with them and the vehicle. The vehicle must be ready for a charging current of 1,500 A. There are many challenges here, so we are all the more proud to have already tested two or three successful charging processes.

So, are you nervous ahead of the demonstration tomorrow?

Jitters are normal; 1,000 kW is simply not routine. We have prepared well for tomorrow and are ready to show the public what we have developed and achieved as a consortium. Demonstrating 1,000 kW in front of high-ranking representatives from business, science, and politics is quite different from repeating it under laboratory conditions until it works.

Speaking of consortiums, other megawatt charger co-operations in Germany sometimes only take place in tandem between truck and charger manufacturers. Why did you and your partners at NEFTON decide to form a consortium?

We started the project three years ago, which means that we started thinking about it almost four years ago. Back then, megawatt charging was completely new territory, and no charging station manufacturer was ready for it. However, we were lucky enough to find partners who were able to develop one of the first megawatt charging points together. It also makes us proud to have developed solutions from a drawing board that we can demonstrate today because that is research.

You just mentioned that the project started three years ago – in other words, in 2021 – and since then, electric truck development has been tremendous. Do you sometimes feel caught up in the market dynamics?

It’s great to see how quickly this market is developing. And I also think we played a part in creating this momentum, particularly in the megawatt charging sector. With our application-oriented research, we are always very close to what is happening on the market, so we inevitably feel driven forward from time to time. As a rule, however, we still drive the market ahead of us. For example, our charging station is already equipped with bidirectional charging and the corresponding communication via ISO 15118-20. The market has yet to catch up.

Do you see great potential in V2G charging (Vehicle to Grid)? How does that fit with strictly timed freight transport, where trucks are less likely to stay connected to the charging station but should be back on the road as quickly as possible, especially at megawatt chargers?

It is true that heavy-duty vehicles drive significantly more than passenger cars, but apart from multi-shift operation, trucks are also parked for at least 14 hours a day. Of course, not all of them are always connected to a charging station, but there is great potential here. How much can be saved through smart depot electrification depends on individual circumstances. Do you have space on the roof for solar panels, or are the vehicles parked at the depot overnight and not at the driver’s home? We were able to reduce energy costs by up to 90 per cent for the depot we assessed, and that’s something you should definitely look into. Whether you do this via MCS or CCS depends on which chargers you have. The output can also be significantly lower.

What other findings from the project on the feasibility and economic viability of electric road freight transport have surprised you so far?

At the beginning of the research project, the race between battery-electric and hydrogen-based drives was quite open from a purely technological point of view. With NEFTON, we took a holistic approach right from the start. That means that we also closely examined the topic of energy systems and bidirectional charging. Taking this into account in the profitability analysis can significantly reduce life cycle costs. It also includes the integration of photovoltaic systems at depots. If you get this right, you can, to exaggerate a little, charge almost for free. Personally, I think that there is still an incredible amount of potential in linking logistics with the energy sector. We need to link these sectors intelligently.

You mention hydrogen drives. What do your project results mean in concrete terms for the future role of other technologies, such as hydrogen or even overhead-line electric trucks?

We definitely see the potential for hydrogen-based drives to represent an economical alternative in niche applications. However, technological and price developments in battery systems will make these niches even smaller. From a technical perspective, overhead-line trucks initially make sense, as the battery system can be significantly smaller and, therefore, lighter and cheaper. The greater challenges lie on the infrastructure side. From a cost perspective, it is difficult to assess because we don’t know who would operate the system, and it is difficult to establish a free market. However, I would categorise the procedural hurdles as greater. If a charging station doesn’t work, you can usually drive to the next one. What do you do if part of the overhead line is out of order for a day? Reliability is a big issue in logistics.

That is why the call for a reliable charging infrastructure is getting louder and louder. The German government just presented the key points for the initial truck charging network in Germany. In your opinion, can the ramp-up work on this basis?

The question is not so easy to answer. The initial charging network is an essential first step with a certain symbolic power for the entire industry. The initial charging network should be seen as part of the public charging infrastructure. Some car charge point operators are already opening their charge points to electric trucks. Many logistics companies are considering opening up their private charging infrastructure if it is not used by their own vehicles. However, it is also clear that the transformation will take place quickly if the emissions targets are to be met. Accordingly, appropriate network connections should also be considered at the 350 tendered locations to enable rapid scaling.

In your opinion, how is Germany doing internationally in terms of the electrification of road freight transport?

Compared to the rest of Europe, we are currently taking very valuable steps, even if the discontinuation of subsidies has left many hauliers uncertain. The vehicle manufacturers’ offers are ready, charging infrastructure operators such as Milence and Citywatt are opening charging parks for electric trucks, and if you look closely, you can see the first vehicles on the motorways. As a nation, we have the opportunity to actively shape this transformation. The approaches are there. Now it’s time to implement them. We can also see that other countries, especially in Eastern Europe, are looking to us for inspiration. That also means that it is up to us to rapidly decarbonise European freight transport.

If we look a little further afield, we see a very similar dynamic on the American market; the National Zero-Emission Freight Corridor Strategy also enables the use of battery-electric trucks there, even if the challenges are greater due to different vehicle deployments.

Let’s return to your charging demonstration. What significance does this day have within the NEFTON project, and what else do you have planned until the project ends in mid-2025?

The demonstration is the central goal of the research project. We need megawatt charging to ensure reliable and time-efficient use in long-distance transport. However, we also realised early on that we are close to series development with a megawatt. The MCS charging standard is specified for up to 3000 A. In the vehicle, that means full charging in less than 15 minutes. It is precisely where we want to be. When the current is tripled, most of the challenges relating to thermals and losses are multiplied by nine. We won’t demonstrate that in the vehicle, but we will present a test bench covering everything from the charging cable to the vehicle battery systems.

Remarkable. When can we expect to see 3 MW chargers in public use?

The first question is: when will we need 3 MW chargers for road freight transport? That is either the case when you have very short idle times, for example, in multi-shift operations, or when autonomous transport is introduced when you are no longer bound by driving and rest periods. In both cases, 3 MW opens up a certain kind of flexibility and optimisation potential. The exciting question will be: What does the kWh cost at a 3 MW charger, and are you prepared to pay that? We are currently developing the technologies and considering how we can integrate them into the vehicle. Whether we see 3 MW perhaps in 2030 depends, in my view, on many factors, not just technical ones.

And what will your employer – the Technical University of Munich – do with the project results? What role do you want to play in the ramp-up of electric mobility in the commercial vehicle sector in the future?

First and foremost, we are responsible for the transfer of knowledge from research to industry and society. We support everything from logistics companies to the German Council of Economic Experts to contribute to rapid implementation. Furthermore, new research projects are constantly emerging from current projects. In SPIRIT-E, for example, we are working on scalable solutions for depot electrification. The core aspects are the sharing of charging infrastructure and the integration of reservation systems for charging points.

A second important area for us as TUM is entrepreneurship. Logistics has great potential in terms of electrification and digitalisation. There is potential for innovative startups in this sector. Here, too, we are active. One of our startups is working is working intensively on interconnecting logistics and the energy industry and is currently in the founding phase.

How can research contribute to accelerating the electrification of road freight transport?

Research is the essential initial step in a transformation. Let’s stay with the specific example of the decarbonisation of road freight transport, which results from the findings of climate research. A targeted transformation is impossible without analysing various drive technologies and piloting different solutions. It is the task of research to point out paths and identify the most sensible ones. And this must be done free of economic interests or personal feelings. That applies to the entire value chain, from battery cell research to recycling approaches. The symbiosis of research and science with industry is our strength in Germany, and we should maintain this.

Mr Zähringer, thank you very much!

0 Comments