HaPiPro2: Research project on efficient drive production comes to an end

As part of the project launched in 2021, PEM and industrial partners such as Ford, Engiro, Thyssenkrupp Systems Engineering, AMS Anlagenbau and Berg & Co Spanntechnik developed and trialled a concept for the flexible and sustainable production of electric motors. To this end, a prototype demonstration line was set up in a research facility on the Ford factory premises in Cologne-Niehl.

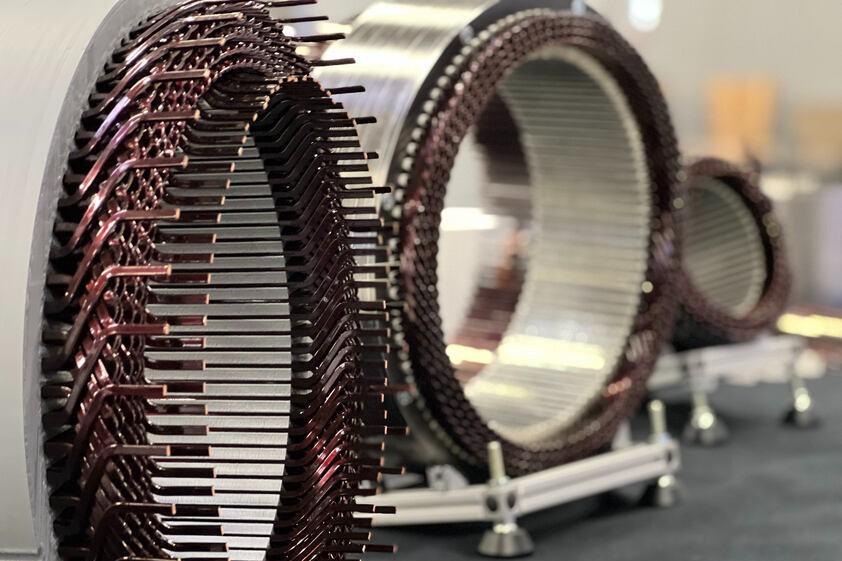

Different stator variants were manufactured on this production line using the same process technologies and production systems in order to increase the economic efficiency of stator production in the long term. According to the press release, the consortium has also succeeded in producing hairpin stators for both passenger cars and heavy commercial vehicles such as electric lorries on the same production line. “It is possible to design the production process chain in such a way that the manufacture of electric motor stators becomes flexible in terms of variants and therefore significantly more efficient,” said PEM Director Professor Achim Kampker at the conclusion of HaPiPro2.

The abbreviation refers to hairpin technology, a wire-winding method used in the production of electric motors. Compared to wound copper wire, the hairpin-shaped copper rods increase the amount of conductive material in the motor, which increases the power density.

PEM has announced that it will continue to work on the production of electric motors and their optimisation even after the project, which was funded by the state of North Rhine-Westphalia with 5.3 million euros, has been completed. “In addition to expanding the infrastructure also for the rotor component, the plan is now to implement digitalization systems along the production process chain. Digital tools such as predictive maintenance and predictive process parameter control are suitable for significantly improving the efficiency of numerous production steps,” PEM reports. In addition, the prototype stator production line set up as part of the project is to receive a ‘digital twin’ for downstream process and production simulation in future.

0 Comments