REWIND consortium researches the direct recycling of batteries

Fraunhofer Institute for Silicate Research ISC, BMW, IBU-tec and Leclanché are among the partners in the research project, scheduled to run until the end of 2027. According to the Fraunhofer Institute, the core of REWIND is “to develop a LIB cell with specially designed recyclable electrodes and cell designs.” It would allow cathode and anode active material, as well as conductive carbon black and cell housings, to be regenerated using partially automated water-based and energy-efficient processes and used directly in new batteries.

The project hopes to create a lithium-ion battery whose prototype is not only recycling-friendly, but whose components can also be recovered while preserving their structure. After just one regeneration step, the recyclates can then be reused directly in cell production, at least in theory.

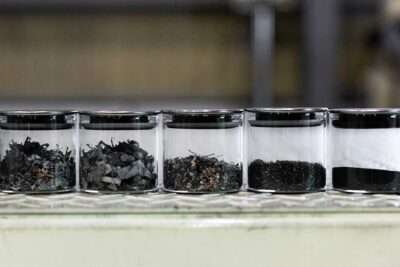

The background: direct recycling promises to conserve resources and potentially reduce production costs (by eliminating the high-temperature step during the synthesis of the active materials), but no such process has yet been established in the industry. “At present, the cells are usually mechanically shredded and then further processed by hydrometallurgical methods – with the extraction of many elements, but with the loss of the functional materials,” the Fraunhofer ISC explains.

In contrast to conventional recycling methods, REWIND’s direct recycling will be characterised by the recovery of functional but less “valuable” cathode active materials such as lithium iron phosphate (LFP) and anode materials such as graphite. “Due to the growing demand for LFP and its importance in battery technology, REWIND is focusing on this material,” the press release states. In addition, the concept will be transferred to sodium-ion batteries to expand the application possibilities of the developed technologies.

The Fraunhofer Institute cites sufficient labelling of the ingredients in the battery cells as a prerequisite for the approach. This is why this topic is also part of the project scope: the REWIND team wants to advance labelling, for example, in cooperation with Prof. Dr Karl Mandel from the Friedrich-Alexander University of Erlangen-Nuremberg, through the use of marker particles that enable simple and reliable identification of the ingredients.

Public projects such as AutoKlass, IDcycLIB, AdRecBat, NaKlar and ReUse laid the foundations for REWIND. “These projects have not only created valuable knowledge and a robust infrastructure but have also paved the way for efficient work in the REWIND project,” says Dr Andreas Flegler, head of the Fraunhofer R&D Center for Electromobility and initiator of REWIND. In his view, the project offers the opportunity to “close the cycle of direct recycling, to develop a profound understanding of the overall process and to develop innovative process steps.”

The project will also establish a centre of excellence for direct recycling. According to the Fraunhofer Institute, it will be a platform for interested industrial companies such as plant manufacturers, OEMs and material manufacturers.

REWIND will run until 2027 as part of the Federal Ministry of Education and Research’s BattFutur programme. In addition to Fraunhofer ISC, BMW, Ibu-tec and Leclanché, the complete list of participants also includes Carl Padberg Zentrifugenbau, EurA AG, Friedrich-Alexander-Universität Erlangen-Nürnberg, Himmelwerk Hoch- und Mittelfrequenzanlagen, Netzsch-Gerätebau, Porsche eBike Performance and WeSort.AI GmbH.

0 Comments