Cellcentric starts FC system pilot production

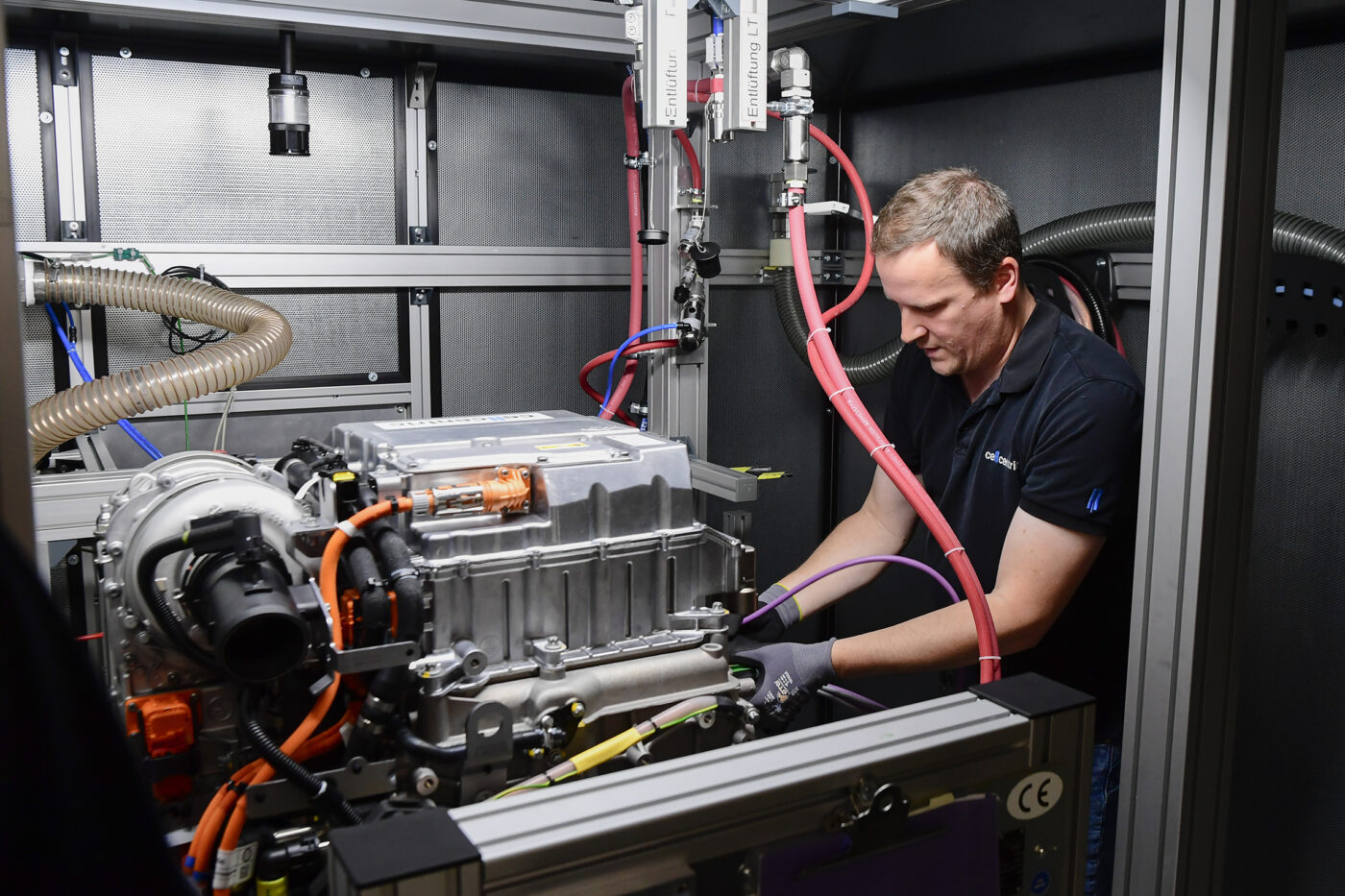

Earlier this year, the company announced its ‘Next-gen’ fuel cell system with a maximum peak output of 375 kW and a low weight thanks to a highly integrated single-system package solution. That is precisely the fuel cell system now rolling off the production line in southern Germany.

The large-scale production will not take place in Esslingen. In fact, Cellcentric says it wants to set up “Europe’s largest fuel cell production in a new factory in Weilheim towards the end of the decade.” However, construction work there has been delayed and will commence in autumn of this year.

The joint venture was founded in March 2021 and aims to produce fuel cells for electric commercial vehicles. The company took over the building in Esslingen, and many of the current 350 employees, from Daimler AG, including from the passenger car division. The fuel cell expertise, initially spread across the various divisions of Daimler AG, was later concentrated in commercial vehicles and then transferred to the Cellcentric joint venture. Since the split of Daimler AG into the Mercedes-Benz Group (passenger cars and vans) and Daimler Truck with its trucks and buses, the passenger car division has virtually lost access to its former fuel cell developments.

Incidentally, the two joint venture partners are pursuing different approaches: The Volvo Group favours conventional hydrogen, i.e. hydrogen stored in gaseous form under 350 bar pressure. On the other hand, Daimler Truck favours liquid hydrogen cooled to -253 degrees Celsius, as this has a higher energy density and enables longer ranges. However, this technology is not widely used, especially in terms of infrastructure.

0 Comments