Porsche Engineering fine-tunes digital battery twin

Porsche Engineering is a wholly-owned subsidiary of Porsche AG with its headquarters in Weissach, Germany and, like Porsche Consulting, offers services for third parties. Like its consulting sister, Porsche Engineering has its roots within the company but has specialized in technical development services for a wide range of customers for many years.

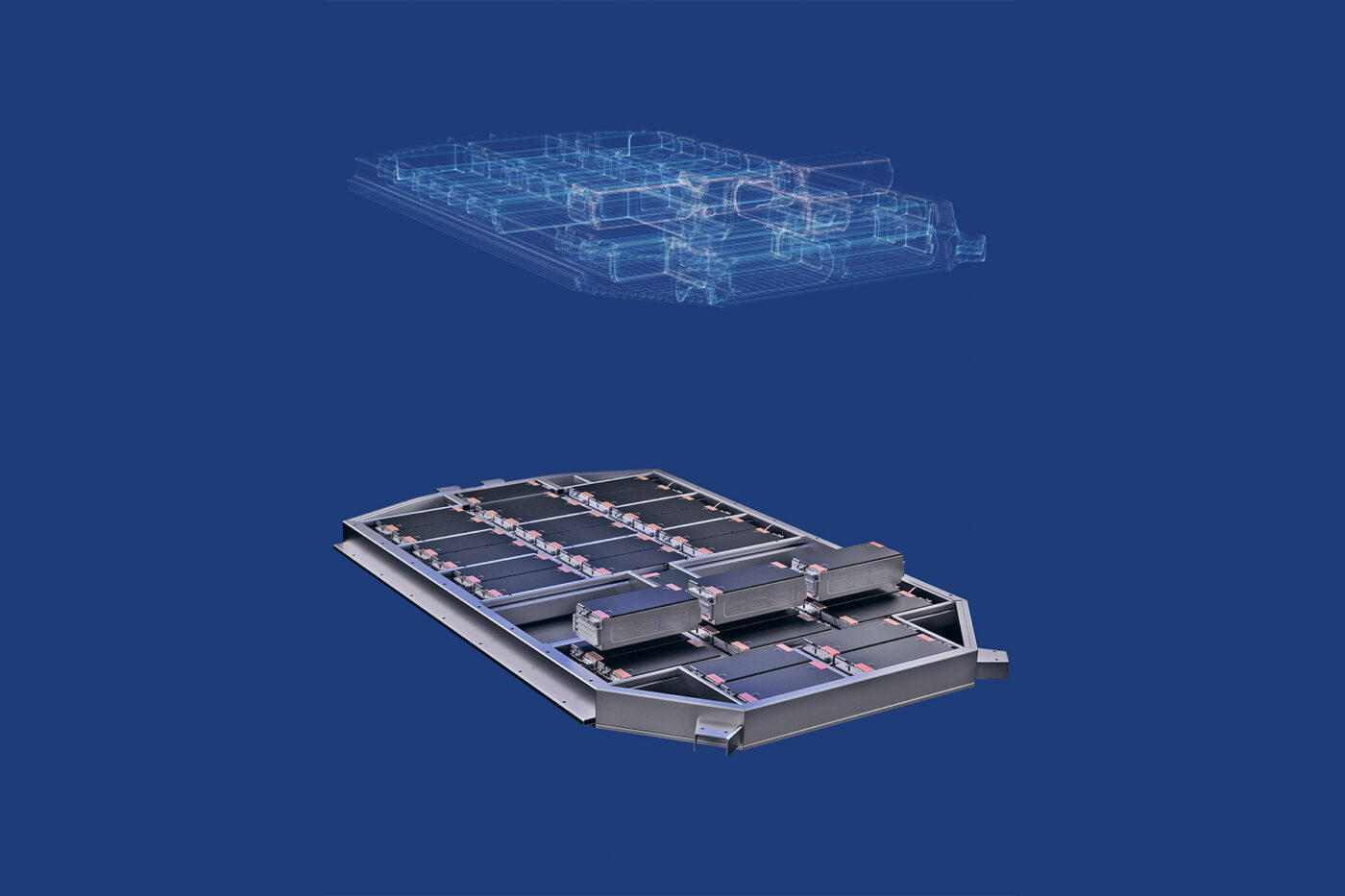

With a view to the emerging electric era, Porsche Engineering describes batteries as the decisive component of electric vehicles – among other things because they have a significant influence on residual value. To understand in detail how battery cells and systems age and what influence usage behaviour has on their service life, the company has been developing a so-called digital twin since 2023 – and is now announcing the first interim results.

“We need to understand how the cells will behave in the field over the long term—without being able to draw on many years of experience, as is the case for the combustion engine,” explains Joachim Schaper, Head of AI and Big Data at Porsche Engineering. The twin is therefore intended to provide a glimpse into the future, with the digital representation of the battery behaving exactly like the original and thus providing information about the expected ageing process. The engineering subsidiary says the digital twin can also be used to improve the service life and performance of the battery.

AI experts at Porsche Engineering in Germany and the Czech Republic report that they have now created prototypes of the electrochemical and thermal models that are now being combined with AI analyses. Work on the Digital Battery Twin has already resulted in an initial function with repair prediction, based on a machine-learning algorithm that monitors the battery data and warns of signs of wear or anomalies.

To create a digital twin of the battery, several data sources are required. A so-called performance module serves as the basis to describe the electrical behaviour of the battery in a simplified manner and can build on established approaches (such as the resistor-capacitor model). In addition, there is a more complex electrochemical model that simulates the processes in the battery cell. Another pillar is the thermal model, which can be used to predict how the battery reacts to cold or heat.

In the case of Porsche Engineering, these models are mainly based on laboratory tests with individual cells or cell modules and can only predict to a limited extent how the battery will behave in the vehicle. This is why real field data is used from test vehicles or from test benches on which cells are measured. This is supplemented with data from the fleet if the customers participate in a data exchange program. The field data is used to train AI algorithms to recognize patterns in customer usage behaviour. Temperature or voltage deviations in individual cells, for example, can indicate premature wear and anomalies.

However, Porsche Engineering states that an AI can only recognize aspects for which there is a database in the field. It cannot make statements about long-term ageing effects, as hardly any electric vehicle on the road is older than four years. This is why the engineers at Porsche Engineering are bringing both worlds together: “Success lies in combining existing model-based components with AI methods,” explains Adrian Eisenmann, development engineer at Porsche Engineering.

Some start-ups are already focusing exclusively on analyzing battery data. But just looking at cells and modules is not enough from Porsche Engineering’s point of view: “You also need comprehensive knowledge of the processes in the vehicle,” emphasizes Head Joachim Schaper, who sees his company at home in both worlds: “For example, the engineers have developed large parts of the battery management system for Porsche e-vehicles as well as pulse inverters for the drive. At the same time, Porsche Engineering employs highly specialized battery data scientists.”

The company’s long-term goal is not only to create a general Digital Battery Twin but also a digital representation of individual vehicle batteries in the future. “It could run in the cloud and, on request, provide customers with information on how their behaviour can extend the service life of the battery without compromising driving performance,” says Porsche Engineering. Some factors that have a positive effect on durability are widely known: The state of charge (SoC) should be kept constant between 30 and 70 per cent and extreme outside temperatures should be avoided. But these are just a few of many factors, Porsche Engineering points out that battery ageing is a complex interplay of many factors that are difficult to separate, especially in the field.

From the Porsche engineers’ point of view, it is even conceivable that the digital doppelganger could be used to personalize the vehicle in the future. “We could analyze the customer’s driving style on request and change the parameters in the battery management system to minimize wear and tear,” they report. Digital twins could also provide important insights for the development of new batteries in the future – possibly even outside the automotive industry. Comprehensive data collection on the wear and tear of batteries also enables better use in second-life applications such as stationary storage, such as undertaken by the company Voltfang, or The Mobility House. Scharper also notes, “Knowledge about the cells could also be transferred to trucks, e-bikes and boats.”

With reporting by Cora Werwitzke, Germany

0 Comments