Vibracoustic presents decoupling system for thermal management applications

The decoupling system optimises the grouping of thermal components such as heating, ventilation and air conditioning (HVAC) to save space, increase efficiency and streamline assembly. The thermal management system has proven its performance and reliability through extensive testing and benchmarking and is ready for series production.

Dr Jörg Böcking, CTO at Vibracoustic, explained: “This project was an important opportunity for us to elevate NVH management in next generation battery electric vehicles. Co-locating thermal systems offers a number of benefits to OEMs, but it also creates substantial new challenges. As a global leader in NVH solutions, our team developed a bracket and mounting system that effectively cradles and isolates the consolidated systems, improving vehicle refinement. This project demonstrated our ability to apply comprehensive NVH expertise at every point in the supply chain, helping our partners overcome complex challenges at the forefront of sustainable mobility.”

As car manufacturers continue to expand and improve their range of battery electric vehicles, the focus has shifted from introduction to optimisation; the technical emphasis has shifted from implementing new technologies to seeking continuous improvements in performance, comfort and fine-tuning. These efforts are centred on the powertrain and battery systems, but also include key thermal management systems – and this is where Vibracoustic has come in.

Accommodating these thermal systems in electric cars from manufacturers looking to maximise space in the high-market SUV segment has so far proved challenging. By co-locating or ‘bundling’ the thermal systems rather than separating them in the vehicle, car manufacturers can save space while simplifying the complexity of integration and the length of hoses and cables. This reduces pressure losses between the thermal components and improves system performance and efficiency. It also makes installation and access for servicing much easier.

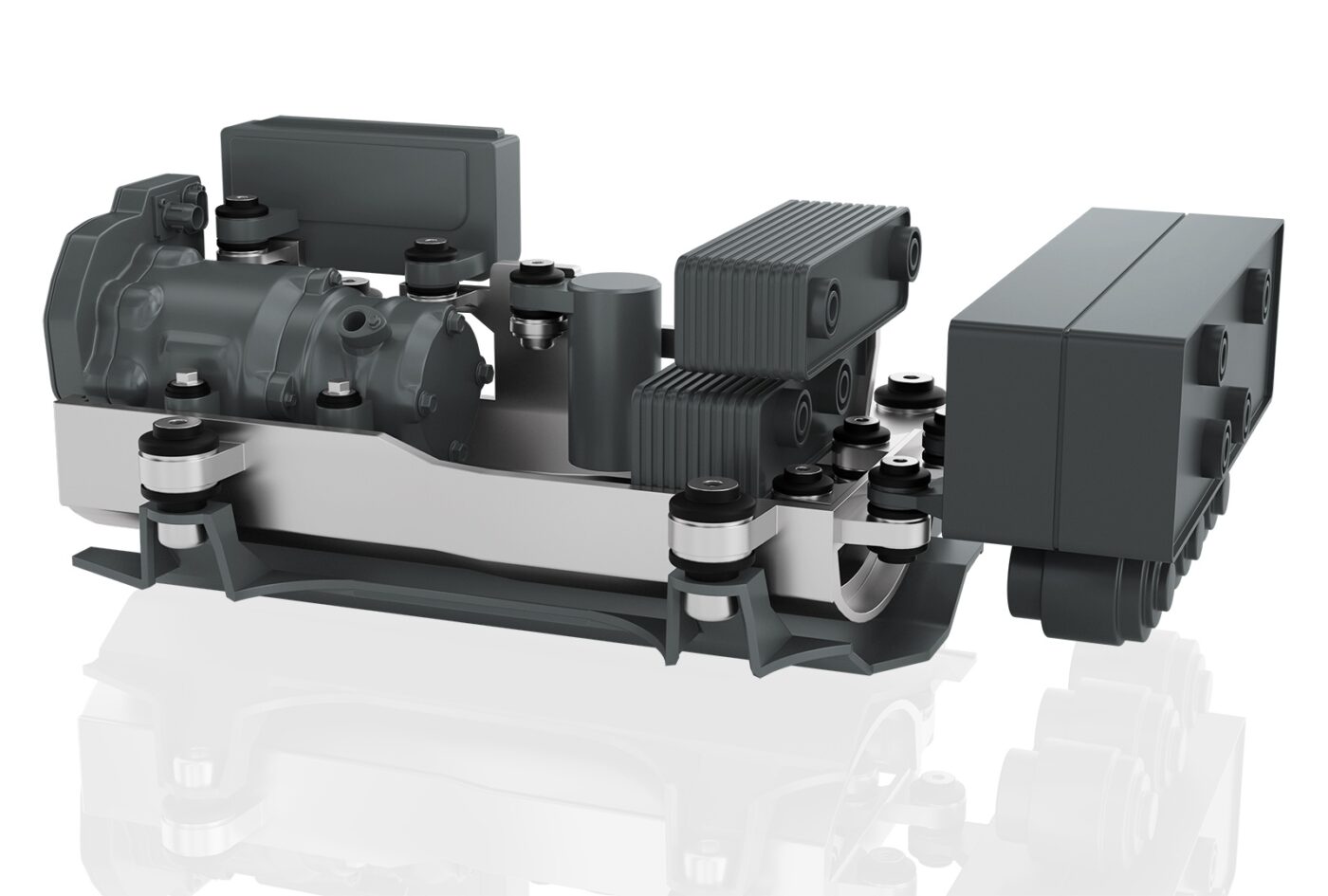

Vibracoustic’s decoupling system for thermal management systems has been adopted by leading international car manufacturers for the next generation of large electric vehicles such as SUVs, pick-ups and vans. In these programmes, the bundled thermal module consists of an air conditioning compressor, an accumulator, pumps and a heat exchanger, among other things. This module is mounted directly on the vehicle chassis and connected by hoses and cables.

Given the myriad of different excitations, noises and vibrations that result, decoupling the combined systems required a holistic approach to NVH design and reduction. Prior to Vibracoustic’s involvement, early design approaches proved to be too stiff and heavy, resulting in weight, cost and packaging penalties. Vibracoustic engineers were able to rethink the design and come up with an innovative solution that took a number of aspects into account. These included the effects of mounting points, cables and hoses on the stiffness and damping of the overall system, as well as all the excitations and interactions of the bundled systems.

Vibracoustic has worked with car manufacturers and suppliers to develop optimised solutions that isolate this complex system from the vehicle chassis. The special bracket design allows the combined systems to be mounted in different vehicle platforms. These strong and lightweight die-cast aluminium brackets have been fitted with custom rubber bushings to ensure optimum overall isolation.

0 Comments