Vitesco implements Kyburz’ battery recycling process

Kyburz and Vitesco are joining forces and expertise to bring the next generation of recycling systems for LFP batteries to market maturity, as Vitesco writes in a press release. Kyburz will contribute its “expertise and practical experience in battery recycling”, while Vitesco has “extensive expertise in (process) automation and production technology.”

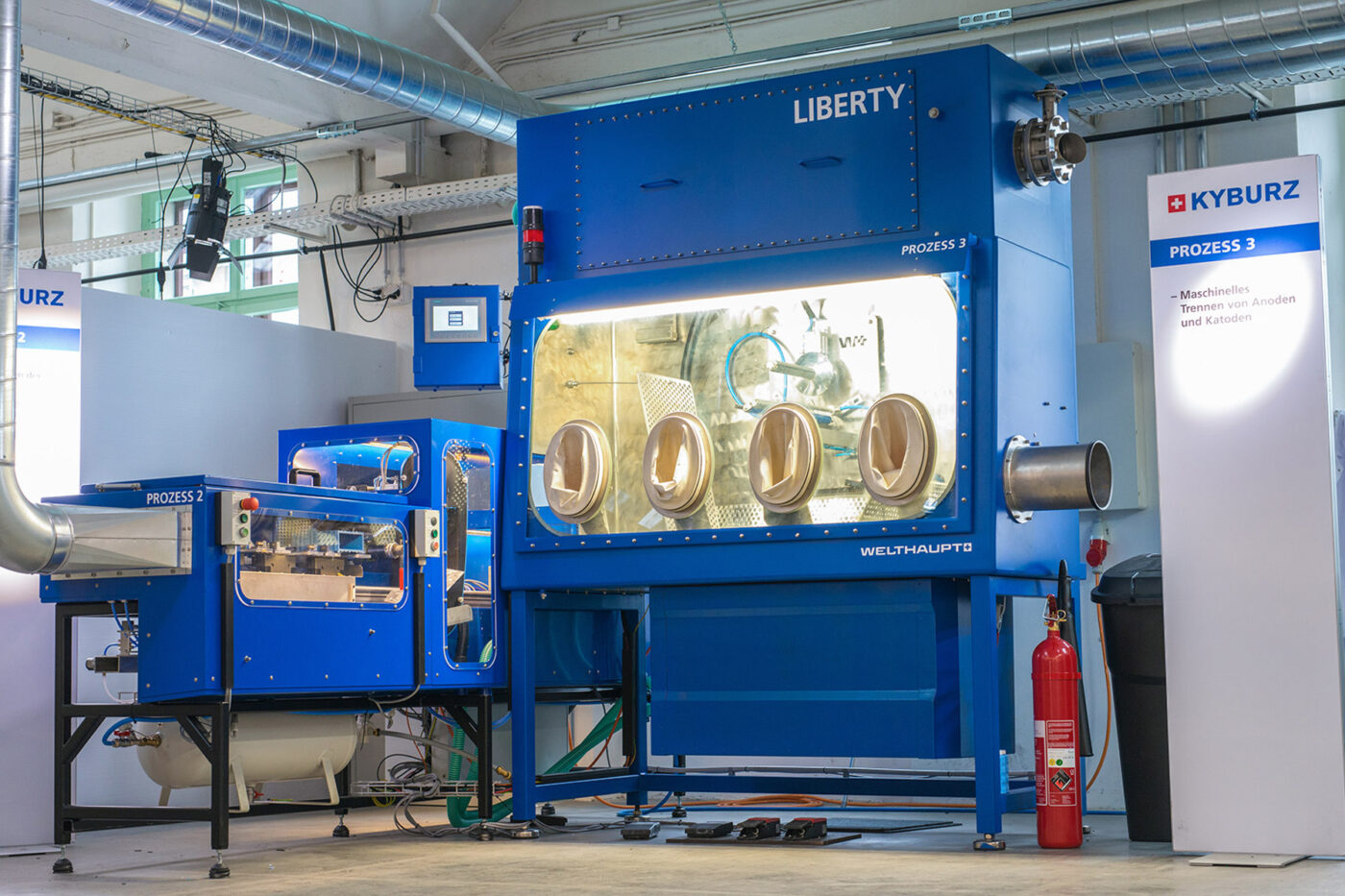

Kyburz has already been operating a first recycling plant at its headquarters in Freienstein, Switzerland, since 2020, and a further developed version of the plant called ‘Liberty’ is to be built in Limbach-Oberfrohna, Germany. The process developed by Kyburz is a direct battery recycling process. The active materials of the battery are extracted in such a way that they can be reused directly for the production of new cathodes and anodes.

In classic battery recycling, the active materials are broken down into the individual raw materials from which new primary products can then be manufactured. The advantage of this is that the exact composition can be adapted each time – for example, a more modern NMC811 cell chemistry can be produced from an older, recycled NMC532 battery. The disadvantage, however, is that splitting and re-forming the materials requires a lot of energy – and therefore drives up costs.

This is precisely one of the points that Kyburz wants to address with its recycling process – in order to tackle one of the major challenges for battery recyclers. The trend towards more cost-effective battery chemistries such as lithium iron phosphate or sodium ion technology is driving down the cost of new batteries. Therefore, the process costs for recycling must also fall in order to recycle such low-cost batteries in a way that covers costs.

“There is no doubt in our minds that electromobility is coming. The key to this is low-cost batteries, which however make recycling these batteries unattractive for many recyclers. With our processes, we are helping to resolve this conflict of interest,” commented Martin Kyburz, CEO of Kyburz.

At the Vitesco site in Limbach-Oberfrohna, which has decades of experience in the field of process automation and production technology, this process is now to be made suitable for series production. For Vitesco, this not only means a potential business area in battery recycling, but also “another attractive future prospect for the Limbach-Oberfrohna site”, as plant and site manager Carsten Czenkusch puts it. This is because series production of diesel injectors will be phased out there by 2028. “With sustainable battery recycling, we are bringing a promising future technology to the site – naturally also with the aim of securing jobs in the long term,” said Czenkusch.

0 Comments