BorgWarner does business with Xpeng and Polestar

Firstly, the follow-up order from Xpeng: BorgWarner only announced in February that it would be building HVH220 hairpin electric motors for the Chinese manufacturer. These are to be used in the X9 MPV and the next electric B-segment saloon from XPeng. Production is scheduled to start in the third quarter of 2024. Just three months later, BorgWarner announced that it would also be supplying engines of the same type for two SUV models from the Chinese manufacturer. The Americans have not disclosed the order value. However, production is scheduled to start in 2025.

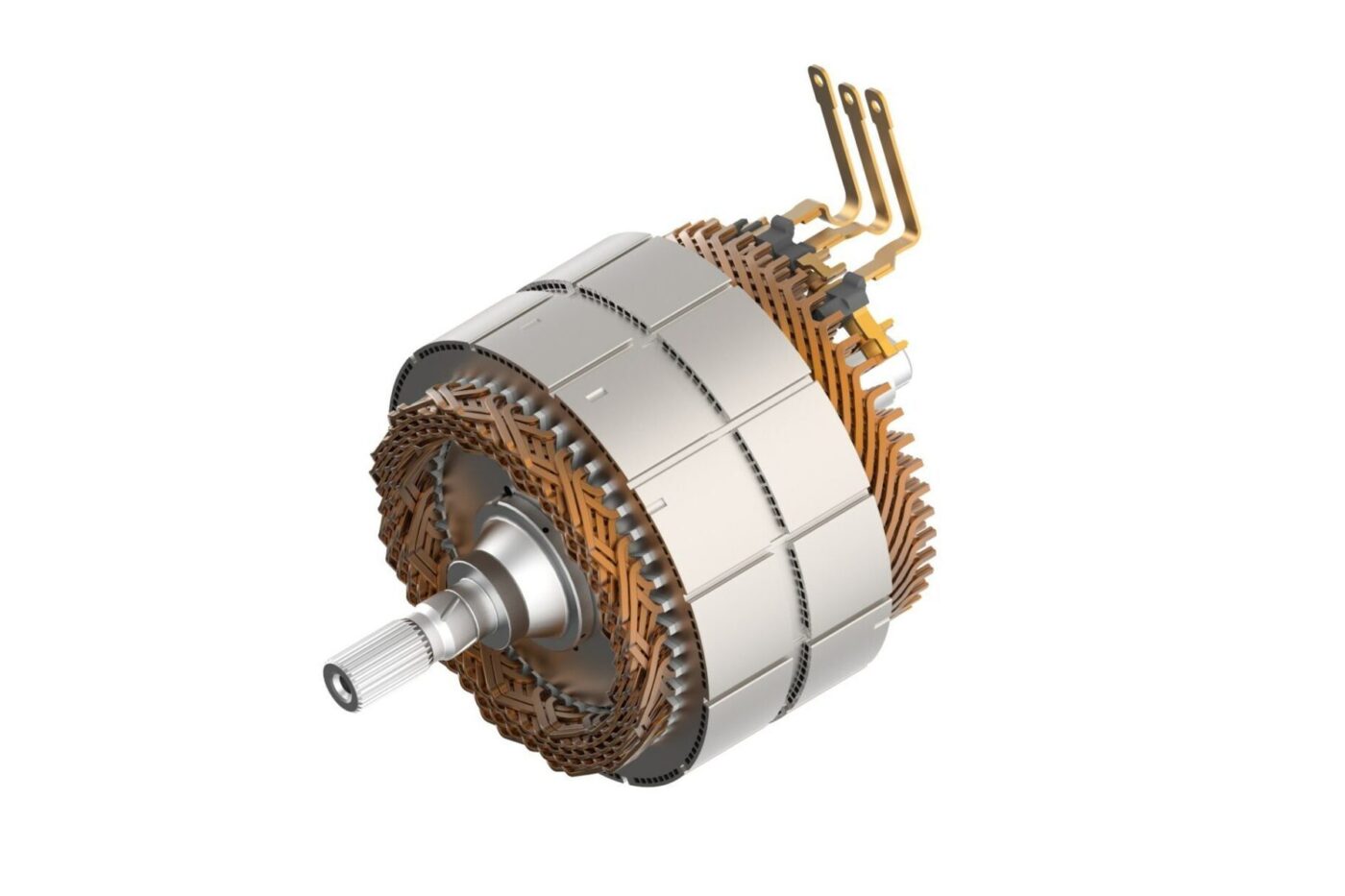

The HVH220 motor from BorgWarner can be operated with a voltage of up to 800 volts and generate up to 300 kW of power. It is based on so-called hairpin winding technology, uses oil cooling and accommodates a stator with the eponymous 220 mm outer diameter. Dr Stefan Demmerle, President and General Manager of BorgWarner PowerDrive Systems, emphasises: “We are very pleased to expand our electric motor business with XPeng, building on our long-standing partnership. We are continuously developing our HVH technology and want to offer our customer maximum efficiency for the two future SUV models.”

At the same time, BorgWarner has announced that Polestar will be the first user of its new torque vectoring with integrated axle disconnection. The system, called ‘eTVD’, is currently in production in the Polestar 3 SUV. Production for another unnamed major European OEM will start later this year. Torque vectoring is the term used to describe the core of torque management systems. This allows the torques on the individual wheels to be intelligently controlled, which is intended to improve stability, increase dynamics and optimise traction when moving off and accelerating.

BorgWarner describes the eTVD as a 3-in-1 system that replaces a differential and has both torque vectoring and a demand-controlled axle disengagement function. “In contrast to brake-based systems, torque vectoring prevents unnecessary brake interventions, therefore reducing harshness and vibration,” it says. This leads to less wear on the brakes and tyres, thus also reducing particulate emissions.

According to Volker Weng, President and General Manager of BorgWarner Drivetrain and Battery Systems, the market trend is towards more software-defined modules and vehicles. “With the market transitioning to more software-defined modules and vehicles, it is critical to have sophisticated systems in place, like our eTVD, that can precisely and quickly calculate, predict and control vehicle behavior across a wide range of situations. We have received exceptionally positive feedback from customers regarding their test drive experiences and look forward to addressing further market needs with our software, controls, and calibration expertise.”

borgwarner.com (Xpeng), borgwarner.com (Polestar)

0 Comments