VW certifies CATL battery test centre in Erfurt

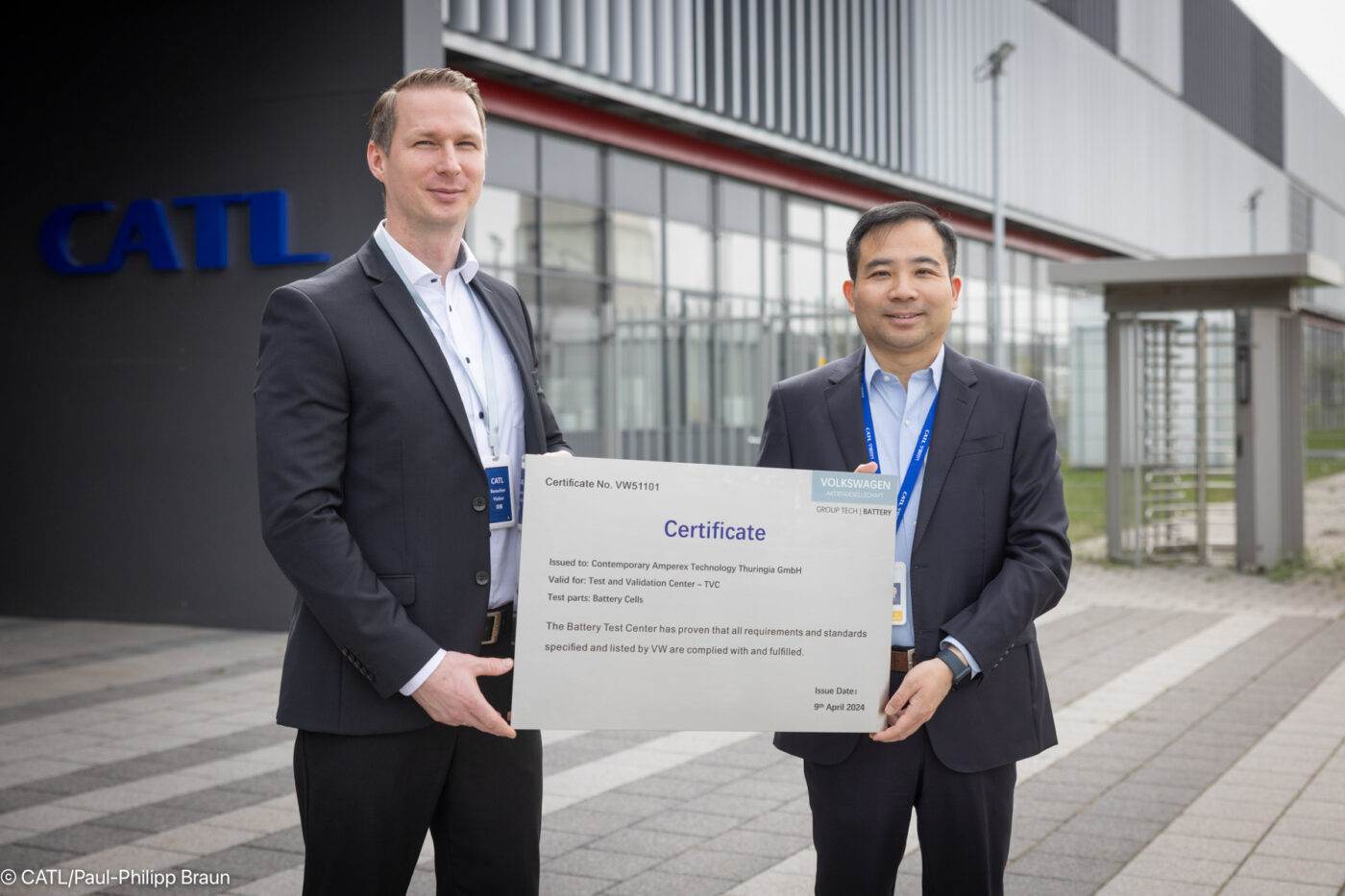

According to the Chinese battery manufacturer, the VW audit was carried out “in accordance with a series of very high and comprehensive industry and VW Group standards in the field of battery testing”, such as electrical characterisation, sequencing, ageing, environmental, mechanical and safety tests. According to CATL, the facility is the first European battery test centre of a battery manufacturer to receive this certification.

The VW Group is also one of the major customers of the CATL production facility at Erfurter Kreuz: the Porsche Macan built in Leipzig, for example, is equipped with battery cells from this plant – and as the Audi Q6 e-tron has the same technical data for the battery, battery cells from Thuringia will presumably also be supplied to Ingolstadt.

The facility at the CATL plant there is “several thousand square metres in size” (CATL is not more specific at this point) and houses “several hundred digitally networked cell and module test channels.” It is operated by a team of specially trained engineers who have been trained to the highest standards in electrical engineering and data science.

The testing facility, which was built with funding from the Thuringian state, is equipped with specialised machinery and infrastructure that enables all types of batteries with different compositions and production formats to be tested for their performance characteristics, longevity and compatibility with modern EV motor platforms. “This includes, for example, simulating different charging points to determine charging efficiency and the impact of high-current charging on vehicle mileage, checking the effects of temperature fluctuations on battery performance down to -30 degrees and testing the battery’s charging and discharging performance by simulating common driving patterns, such as commuters travelling to work,” explains CATL.

From the second quarter of 2024, CATL will expand its offering and provide similar testing services to customers from all sectors of the battery industry “to support them in testing their electrical equipment”, according to the press release. To ensure the high quality and safety of its products, CATL has developed extensive test environments “covering large parts of the company’s global production facilities”. In this way, the company guarantees product reliability with defect rates in the parts per billion range.

CATL has been manufacturing battery cells at the plant in Arnstadt since the end of 2022. The associated test centre has also been active for some time in collaboration with the Fraunhofer Institute for Ceramic Technologies and Systems IKTS, but has only now officially started full operation.

Source: Info via email

0 Comments