Ferroglobe to produce battery materials with Coreshell

The goal of the collaboration is to make it possible to replace silane-based silicon and graphite in the anodes of electric vehicle batteries. This will then make the manufactured batteries more powerful by a factor of up to ten times the energy storage compared to graphite, potentially resulting in a 40 per cent increase in driving range.

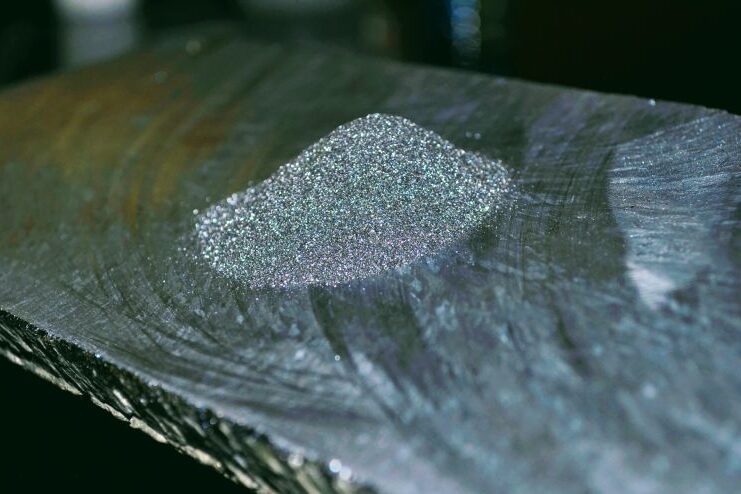

Under the collaboration, Coreshell’s proprietary battery technology will be used, which features a unique nanomaterial electrode coating. This is apparently the only proven solution to mitigate the degradation of micrometric silicon, preventing its rapid loss of life while still allowing lithium ions to pass through.

“We believe battery-grade, micrometric silicon is the fastest path to decarbonizing the mobility industry,” said Benoist Ollivier, Chief Technology & Innovation Officer of Ferroglobe. “When the right battery technology partner and the leading supplier of silicon to the US come together, breakthroughs can happen.”

Jonathan Tan, CEO of Coreshell, explained more about the technical aspects behind the project: “Silicon stores 10 times the energy of graphite and it is available in sufficient quantity and quality. It is the only viable pathway to low-cost, long-range electric vehicle batteries that can be scaled rapidly using a 100% domestic supply chain. The issue to date is that no one has been able to unlock the power of metallurgical silicon, and the high cost and scaling challenges of highly engineered or silane-based synthetic Silicon anodes have prevented the industry from benefiting from its true potential.”

0 Comments