Mercedes eEconic on the road for road safety in Stockholm

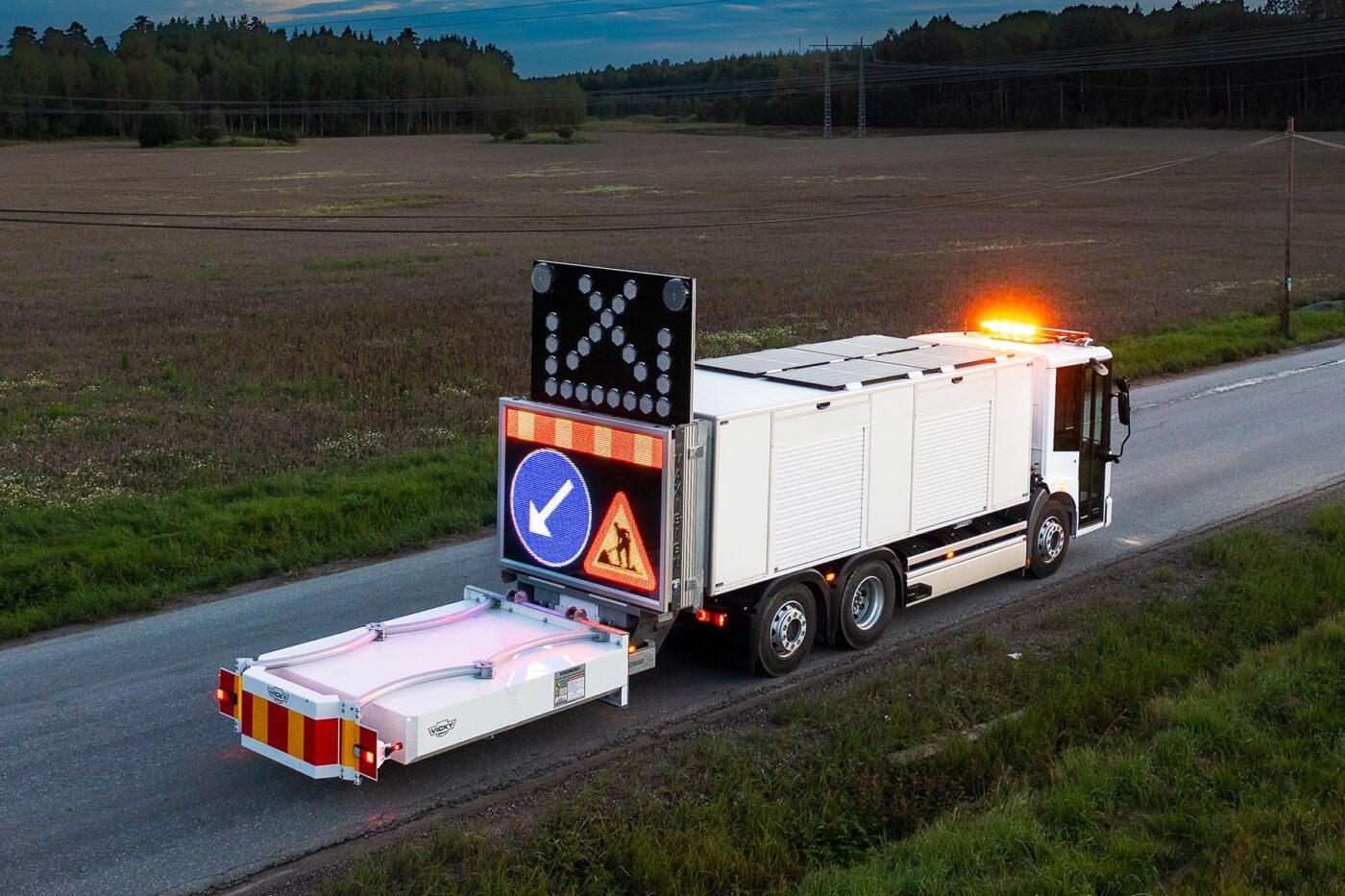

The two eEconic vehicles were equipped by the Swedish company Vicky Teknik, which, according to Daimler Truck, has “many years of experience with TMA bodies.”

The two so-called TMA carrier vehicles from Vicky Teknik were fitted with mobile impact attenuators, also known as TMA or Truck Mounted Attenuators, to secure construction sites of shorter duration, for example. “The special-purpose vehicles are so-called TMA-vehicles, which are equipped with mobile impact absorbers – also known as TMA or truck-mounted attenuator – to secure construction sites of short duration, for example. The truck-mounted attenuator can protect all parties involved in the event of a collision,” the press release states.

In addition, the vehicles are equipped with a separate battery system with approx. 20 hours of operating capacity and solar cells. There are no further details on either the battery system or the solar cells.

The 27-tonne truck is based on the eActros and uses its drive: the two electric motors integrated into the e-axle deliver 330 kW continuous and 400 kW peak power. Three battery packs are installed in the vehicle, each offering an installed capacity of 112 kWh and a usable capacity of around 97 kWh. The maximum charging power is specified as 160 kW. The charging process from 20 to 80 per cent should take 75 minutes. According to Daimler Truck, the range is just under 300 kilometres, whereby, as with other electric vehicles, the application profile influences this.

Daimler Truck has already started series production of the Mercedes-Benz eEconic in summer of 2022. Since then, the electric special truck for inner-city municipal use has been produced at the Wörth site in southern Rhineland-Palatinate. The start of production also marked the announcement of the first customer, the waste disposal company Urbaser A/S from Denmark.

0 Comments