US researchers increase energy density of sodium-ion batteries

In a modification of the familiar NMC cathodes for lithium-ion batteries, the Argonne laboratory’s development is a sodium-nickel-manganese-iron oxide (NMF). Compared to other sodium-ion technologies, the cathode offers a much higher energy density, which is sufficient to give electric cars a range of around 180 to 200 miles (290 to 320 kilometres) per charge.

In NMC cathodes, the atoms are arranged in layers. This structure makes it easy to insert and extract lithium ions between the layers. Based on the findings from a total of ten years of research work with sodium-ion batteries, the team led by senior chemist Christopher Johnson has developed a layered oxide cathode specifically for sodium-ion batteries.

NMF cathode should also increase service life

The layered structure of the NMF cathode should enable the efficient insertion and extraction of sodium ions, according to the Argonne National Laboratory in the press release. And because the cathode material does not contain cobalt, the “cost, scarcity and toxicity concerns associated with this element” should also be mitigated.

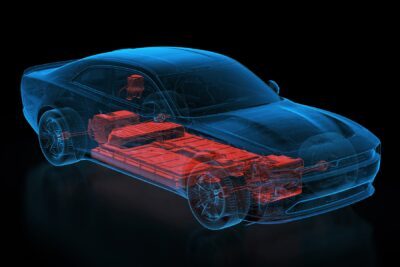

The researchers also want to have eliminated another disadvantage of earlier sodium-ion batteries: their short service life. With the new cathode material, sodium-ion cells achieve a similar number of charge/discharge cycles as their lithium-ion counterparts. “We have now transitioned from the laboratory phase and are poised to subject our cathode to testing within battery cells similar to those in an actual electric vehicle battery,” says Johnson. These tests will be conducted at Argonne’s cell analysis, modelling and prototyping facility.

The advantages of sodium as a battery material are well known: Sodium is far more abundant in nature and is easier to mine than lithium. As a result, it costs only a fraction of the cost per kilogramme and is significantly less susceptible to price fluctuations or disruptions in the supply chain. “Our estimates suggest that a sodium-ion battery would cost one-third less than a lithium-ion one,” says Johnson. In addition, the cathode material contains predominantly iron and manganese alongside sodium.

This is an issue that the research team cannot physically resolve: Sodium metal is around three times heavier than lithium. This increases the weight of the battery and thus reduces the range. Johnson emphasises that while the sodium-ion battery may not appeal to those looking for long ranges, it could attract price-conscious consumers, particularly city dwellers whose daily commute rarely exceeds 300 kilometres.

With the higher energy density of the cathode, the US researchers have already taken an important step towards making sodium-ion batteries attractive to more vehicle segments. According to the press release, Johnson’s team is already developing new materials for the other two main components of a battery – the electrolyte and the anode – to increase the energy density even further.

Update 30 September 2024

Researchers at Argonne National Laboratory have reported progress in developing their new cathode material for sodium-ion batteries. They claim to have overcome a fundamental problem: the energy storage capacity of the sodium-containing cathode decreases rapidly with repeated discharging and charging. According to the scientists, this is due to cracks in the cathode particles during the synthesis process. They did this by finding “heat treatment conditions.”

“The prospects seem very good for future sodium-ion batteries with not only low cost and long life, but also energy density comparable to that of the lithium iron phosphate cathode now in many lithium-ion batteries,” said Khalil Amine, an Argonne Distinguished Fellow. “This would result in more sustainable electric vehicles with good driving range.”

The team is now working on removing the nickel from the cathode, which would reduce costs even further and be more sustainable.

2 Comments