Group14 and SK Materials produce silicon-based anode material

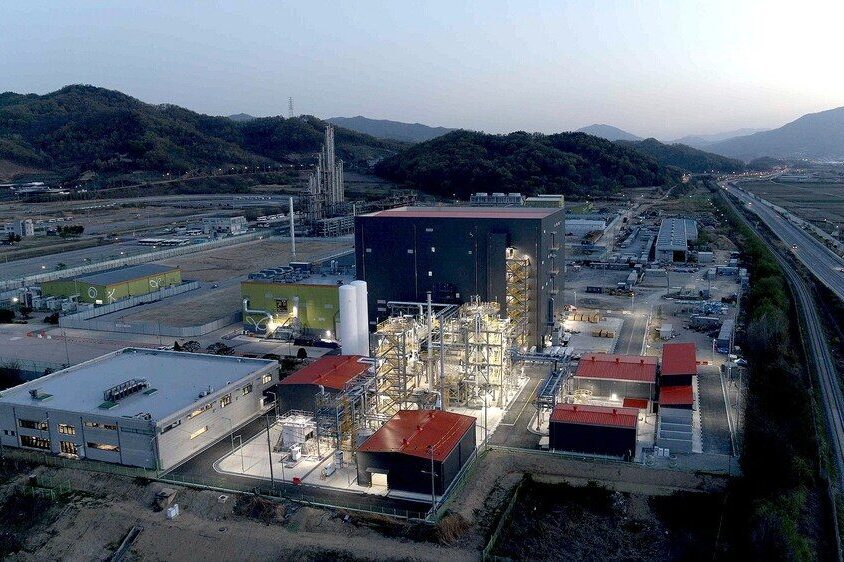

The factory in Sangju in North Gyeongsang Province was built by SK Materials Group14, a joint venture between the US specialist Group14 Technologies and the South Korean company SK Materials. It will initially be able to produce 2,000 tonnes of Group14’s SCC55 silicon-carbon anode material per year – enough for batteries with a total capacity of 10 GWh.

Silicon is used in the anode instead of graphite. As a rule, these are not pure silicon anodes, but an admixture. The rule of thumb here is: the more silicon is used, the higher the energy density of the battery, but also the higher the possible charging capacity.

Compared to graphite, the silicon-carbon composite SCC55 can increase the energy density of a battery by up to 50 per cent, which significantly reduces the cost of a battery pack, explains Rick Luebbe, CEO of Group 14 Technologies. SCC55 batteries can also be charged “extremely quickly” – probably in five to 10 minutes.

“This material is less expensive on a dollar per kilowatt-hour basis at the pack level (than graphite lithium-ion batteries),” Luebbe told The Korea Herald. “Due to its high energy density, we can take a third of the battery cells out of the path and still have the same (driving) range. This results in significant cost savings — lower cost of EVs.”

Commercial operation will officially start at the beginning of next year. “As we finalise commissioning with SK at the joint venture factory, we are seeing tremendous uptake from our customers who have begun reserving supplies of SCC55™ for their equipment and vehicles,” says Group14 CTO Rick Costantino.

Group14, which is supported by Porsche and others, is also building a factory for its SCC55 anode material in Washington State. According to Group14, the campus in Moses Lake will house the world’s largest factory for silicon battery materials for use in electric vehicles.

0 Comments