Kia & Hyundai presents new wheel drive system

The Uni Wheel, presented by South Korean automotive giants Kia and Hyundai, relocates the important drivetrain component of the reduction gear to the free space within the wheel hub. Where the Uni Wheel differs from other in-wheel systems, such as the in-wheel hub motor from Protean Electric, only the reduction gear is integrated into the wheel hub rather than the entire electric motor.

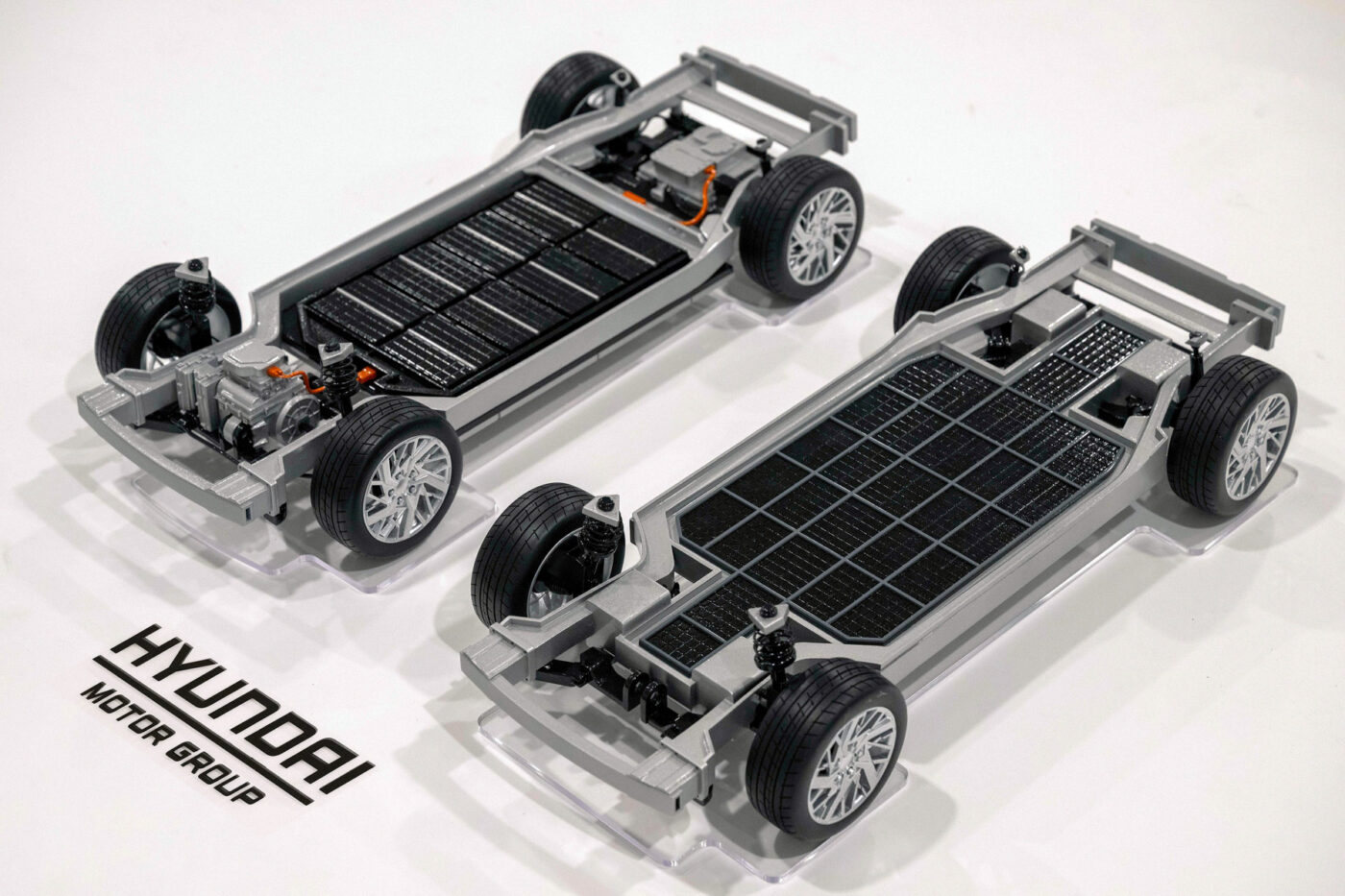

Moving the reduction gear to the wheel hub allows smaller electric motors to be mounted close to the wheels, reducing the length of the drive shafts. Small electric motors can be positioned further out instead of a central axle motor with long drive shafts, freeing up the space between the wheels required for the central motor. Hyundai states that this can be used as additional cargo space, such as a larger trunk or frunk, or different interior layouts in the vehicle. The extra space created can also be used for additional battery modules.

The Uni Wheel uses a special planetary gear configuration consisting of a sun gear in the centre, four pinions on each side and a ring gear surrounding this arrangement. The power generated by the motor is transmitted to the sun gear, which in turn engages with the pinions to turn the ring gear. This is connected to the wheel to drive the vehicle. A special joint mechanism is designed to provide the necessary freedom of movement so that the Uni Wheel can follow the movements of the suspension.

Hyundai and Kia also expect the Uni Wheel to improve driving comfort. In a conventional drive with a central motor (whether electric or combustion), efficiency deteriorates when the deflection angle of the drive shaft increases during compression and rebound. The new system should be able to transmit the power almost unchanged regardless of the wheel movement and thus ensure greater comfort and improved durability of the components. The same also applies when the vehicle’s height is changed by air suspension – which also leads to a higher deflection angle of the drive shaft in the case of a central drive.

The Korean group sees so-called Purpose Built Vehicles (PBVs) as the optimum application area for the Uni Wheel, such as special vehicles for cab services and ride-hailing services, such as those planned by Kia. This mirrors the application areas of other wheel hub motors, such as the motor mentioned above from Protean Electric. Within the Hyundai Motor Group, the Kia brand has been given the lead in PBVs, with the group prioritizing these vehicle types as an essential driver of future business. Kia has yet to specify exactly which vehicles it will build from 2025 or 2028 onwards with its new dedicated plants for these vehicle types. Kia and Hyundai believe that the Uni Wheel has great potential, saying that this vehicle drive system will revolutionize the design of future mobility devices.

Road vehicles are not the only application area envisaged by Hyundai and Kia for their Uni Wheel. The automotive group says the new drive system can also be applied to other mobility devices, such as wheelchairs, bicycles and delivery robots. The Uni Wheel can be scaled to suit small wheel sizes from 4 inches and up to large applications of 25 inches or more. Small personal mobility vehicles can also make the most of Uni Wheel’s ability to move the rotation axis of the wheel so that the vehicle can climb stairs “as smoothly as an escalator,” say the automakers. Although not mentioned, this ability would also suit first responder vehicles.

So far, the South Korean group has not revealed the performance data for the Uni Wheel. In the next step, further tests will be carried out to improve the stability, efficiency and durability of the Uni Wheel. Adjustments to the reduction gearbox and the modernization of the lubrication and cooling system are also mentioned by the automakers in terms of improving efficiency. Hyundai and Kia have registered eight patents relating to the Uni Wheel in South Korea, the USA and Europe.

1 Comment