Bosch starts production of 800-volt drives

Bosch has expanded its eMobility portfolio to include 800-volt systems. With immediate effect, the company is serially manufacturing an electric drive and an inverter with 800-volt technology. The components are said to stand out not only for performance but also for their efficiency.

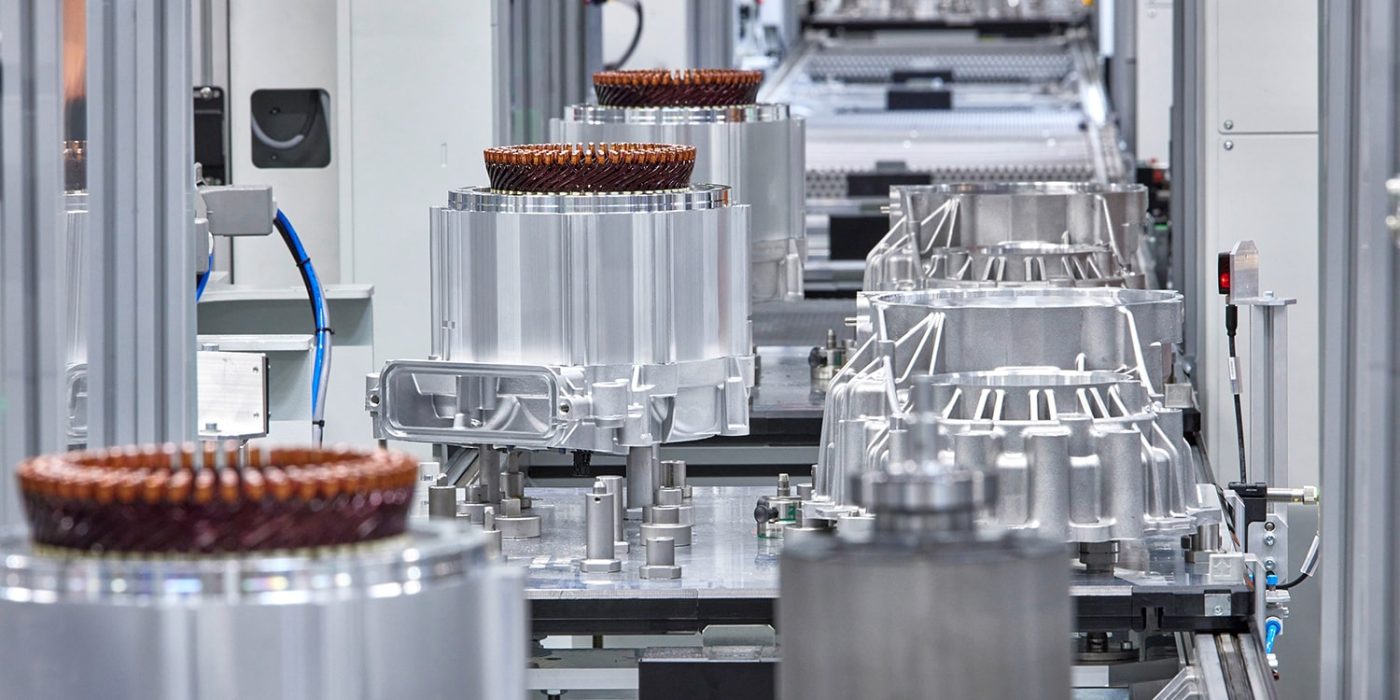

The 800-volt version of the electric motor (a permanent magnet synchronous motor) from Bosch offers a line of 460 kW and a torque of 830 Nm. Thanks to the use of a so-called ‘iPIN’ bar winding, “the motor’s efficiency, compactness, and level of automation in production can be further improved”, the supplier writes. With copper rods instead of wound copper wire (with unavoidable small gaps between the windings), the copper filling level in the stator can be increased.

According to Bosch, in terms of the strength-to-size ratio of a motor, this means a power density of 60 kilowatts per litre that is up to 35 per cent higher. The torque density is 105 Newton metres per litre. At its peak, the Bosch motor thus achieves an efficiency of up to 98 per cent.

The active parts of this drive, namely the rotor and stator, are “used for the first time by a German premium manufacturer” – Bosch does not mention this by name, as is usually the case in the supplier industry. With these limited details, it is not possible to draw conclusions about the car manufacturer, because BMW (New Class), Audi and Porsche (both with the PPE) rely on 800 volts of system voltage. At Mercedes, it is becoming apparent that the EVA-2 platform (EQE and EQS, among others) will also switch to 800 volts with the facelift – but Mercedes relies on its own eATS-2.0 drive unit.

The company, based in Gerlingen near Stuttgart, announces a further development of the 800-volt motor at the start of production: In the next generation, the electric motor will be equipped with oil cooling. This will allow the heat generated in the electric motor to be dissipated more effectively and ensure permanently powerful operation on long-distance journeys or in the commercial vehicle sector.

The 800-volt version of the inverter from Bosch relies on silicon carbide (SiC) semiconductors, which increase efficiency and thus range. Thanks to the SiC chips, the efficiency of the inverters increases to up to 99 per cent, according to Bosch. But the higher voltage level also allows the inverter to be designed slightly smaller, as thinner and lighter cables can be installed for the same power at a higher voltage.

“Bosch is upping the voltage in electromobility. Our 800-volt technology is the next step toward more powerful electrical powertrains and shorter recharging times,” said Ralf Schmid, the divisional board member responsible for electrification in the Bosch Powertrain Solutions division.

1 Comment