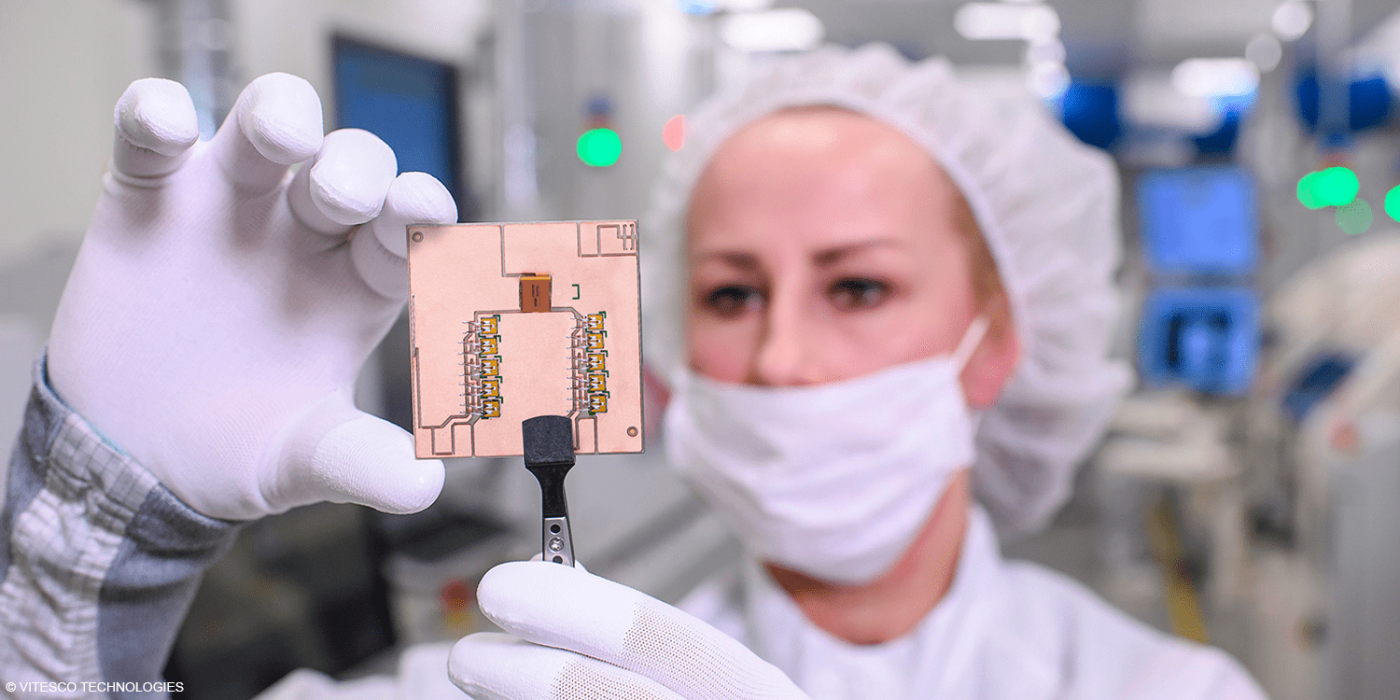

Vitesco orders SiC semiconductors worth billions from Rohm

Powertrain supplier Vitesco Technologies has secured capacity in energy-efficient silicon carbide power semiconductors through a long-term partnership with Rohm Semiconductor – worth more than $1 billion between 2024 and 2030.

According to Vitesco, the development partnership with Rohm began in 2020 and is the basis for the signed agreement. Two car manufacturers will adopt Vitesco Technologies’ inverters with integrated SiC chips from Rohm for use in electric vehicle powertrains. Vitesco says it “will start supplying a first series project as early as 2024”. When the deal was announced in 2020, the partners said production would not start until 2025. “The company is thus even ahead of the originally targeted timeline”.

The SiC chips relevant to the above-mentioned EV powertrains were further optimised within the framework of the joint development project. Vitesco CEO Andreas Wolf describes the partnership as an “important building block for securing Vitesco Technologies’ SiC capacities in the years ahead”. She adds: “We have had very good experience in our development cooperation so far and are now looking forward not only to continuing it, but also to intensifying it further.”

However, the German drive supplier is not relying exclusively on SiC semiconductors from Rohm Semiconductors. At the end of May, Vitesco signed a long-term supply agreement with Onsemi for silicon carbide products worth 1.75 billion euros over ten years. In addition to the purchase of the semiconductors, the companies are also looking to jointly optimise drive inverters.

Rohm Semiconductors is also full of praise for partner Vitesco. “In the high-growth automotive market, SiC is a pathfinder for higher efficiency. With an expected higher market share of more than 30 per cent, we are strongly positioned here and have gained a strategic partner in Vitesco Technologies for further market penetration,” says Kazuhide Ino, Member of the Board, Managing Executive Officer and CFO of Rohm of Vitesco.

With its unique conductive properties, Silicon carbide enables the production of chips for power electronics that are both fast and low-loss switching. At the same time, SiC chips are more thermally resistant, so the power density of electronics can be increased. Thanks to these features, SiC electronics have reduced conversion losses compared to conventional silicon (Si). In other words, more of the energy stored in an EV battery reaches the drive – which increases the range or enables smaller, lighter and cheaper batteries with the same range.

1 Comment