Sakuu unveils 3D printed batteries for licensing

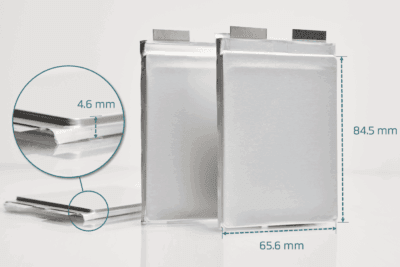

Sakuu, a Californian developer of 3D-printed solid-state batteries, has unveiled a market-ready lithium metal cell chemistry that battery manufacturers can now license. Sample 5 Ah pouch cells are available at Sakuu’s battery pilot plant in Silicon Valley.

Sakuu, which was founded in 2016, says the so-called Cypress cell chemistry offers high performance (8C pulse discharge, 3C continuous discharge) and an energy density of over 750 Wh/l. According to the company, lithium metal battery chemistry offers higher energy density and additional performance benefits but poses a major development challenge due to its high reactivity. The company claims it has solved these problems in collaboration with Cypress by means of novel electrochemistry and lithium metal chemistry that is ready for scalable production. The company has not provided further specifics on this point.

Robert Bagheri, founder and CEO of Sakuu says, “The compatibility with 3D-printing will further enhance the effective use of battery packaging volume with new and unique approaches to thermal management. Li-Metal cells have advantages that Sakuu has made attainable, scalable, and safe.” The CEO speaks of a new paradigm in battery manufacturing and energy storage in this context. “Manufacturers can now license this technology,” he announces.

Sakuu previously said it plans an annual production capacity of 200 GWh for lithium metal and solid-state batteries by 2030. The company has hired Porsche Consulting, a Porsche consulting subsidiary, to plan its targeted gigafactories. Porsche Consulting is to plan a reference gigafactory for the US company with a sustainable setup and maximum production efficiency that “can be efficiently replicated at various locations around the globe”, as Sakuu put it earlier this year.

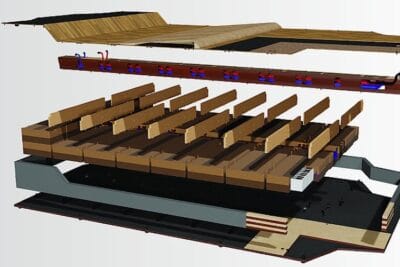

While the first plant will support the production of lithium metal batteries, Sakuu plans to use its so-called Kavian platform solution to produce 3D-printed solid-state batteries at subsequent production facilities. According to earlier information, the self-developed printing process is theoretically also suitable for other industries, but the company sees the greatest leverage in battery production, whereby various additive manufacturing processes will be combined. For example, “completely different materials” can be sprayed onto the powder bed in a single layer. In addition to ceramics and metals, the process uses a carrier material developed by Sakuu called PoraLyte. This support material is said to enable simple and fast 3D printing of components with cavities without brittle ceramic layers.

Sakuu operates a pilot line for solid-state batteries and an engineering centre in Silicon Valley. The latter centre is designed to allow Sakuu to scale its 3D printing battery platform. On the pilot line, the company says it has been “successfully and continuously 3D printing fully functional and high-performance batteries in custom shapes and sizes” since December 2022, saying at the time: “Printing custom-structured batteries in a dry process (…) is a true breakthrough and has the potential to revolutionise battery manufacturing of the future for all industries.”

Sakuu wants to finance its business through an IPO, and the Californian developer is planning this process through a merger with Plum Acquisition Corp. I. The transaction is expected to be completed in the third quarter of 2023.

0 Comments