German research team looks into remanufacturing e-bike drives

Together with partners, a team of researchers from the Fraunhofer IPA was able to show in a study that e-bike motors can be remanufactured in the sense of a modern circular economy. Since the remanufacturing succeeded with almost the same properties, the researchers see great potential in the approach.

In the ‘AddRE-Mo’ project, researchers from the Fraunhofer IPA, together with the companies Cirp, Electric Bike Solutions, the sponsoring association Umwelttechnologie-Cluster Bayern and the Wuppertal Institute for Climate, Environment and Energy, investigated the technical feasibility of remanufacturing electric bike motors.

In addition to the process chain itself, starting from non-destructive dismantling to cleaning, testing, remanufacturing or replacement with new parts and reassembly – the ecological and economic potential of remanufacturing should also be analysed. Because without a viable business model, remanufacturing will hardly be successful despite the ecological benefits.

“At the end of the process chain, remanufacturing delivers a bike motor that is on par with a newly manufactured motor in terms of quality, and also comes with the same guarantee,” explains project manager Jan Koller. The economic savings potential depends on the number of units and is usually around 30 to 40 per cent for comparable components compared to buying a new electric motor. As a result, remanufacturing also offers great potential for the manufacturers of the electric motors.

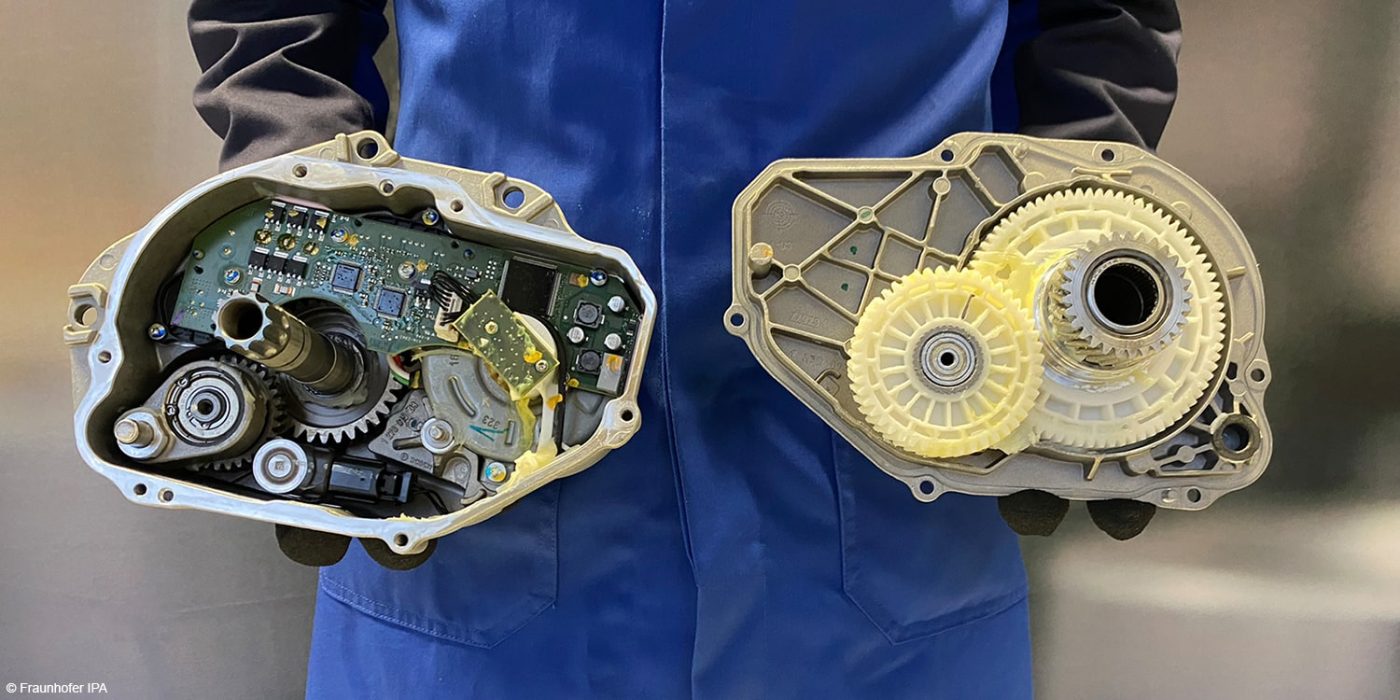

In the first step, Koller and his team examined electric bicycle motors from established manufacturers for their probability of failure. Then they tested whether and under what conditions spare parts with a high wear rate, such as gears and torque supports, can be manufactured additively. The scientists obtained the necessary data for 3D printing either through 3D modelling or 3D digitisation, depending on the geometry of the components. They then selected materials and additive processes. Together with the companies Cirp and Electric Bike Solutions, the Fraunhofer IPA finally manufactured the components and tested their service life, noise development and temperature resistance in specially developed test stands and under real loads. In total, more than 120 components made of 20 different materials were produced from the 3D printer.

What is clear, given the rising sales figures, is that more and more e-bikes are on the road in Germany – according to the German regulatory institute Zweirad-Industrie-Verband (ZIV), electric bikes already accounted for 48 per cent of sales in the overall bicycle market in 2022. These vehicles will reach the end of their useful life at some point. And defects can already occur during operation – but here there is often no replacement, which is why a broken motor is not repaired but exchanged as a whole for a new unit.

“If the motor or battery fails, it’s usually the case that the entire component is replaced, even though it may only be one gear that’s faulty. It is rarely worthwhile for electric bike workshops to repair a motor or battery, and manufacturers also have a vested interest in replacing old motors, which are the biggest cost drivers in electric bikes, with new ones,” says Koller.

To consolidate the results achieved in the project, the process chain of remanufacturing electric bike motors will be implemented and made tangible in the new RemanLab learning factory at the Fraunhofer IPA in Bayreuth, which will open on 23 May 2023.

0 Comments