WAE launches its first mass-market product, the Elysia BMS

WAE Technologies, formerly Williams Advanced Engineering, launched a new battery management system this week. WAE appeared to strike a delicate balance between bespoke and standardly predictive BMS in the press call preceding the announcement. The company claims there is potential performance waiting to be unlocked in almost any of today’s batteries.

***

WAE Technologies is a rebrand of Williams Advanced Engineering after Fortescue acquired the engineering consultancy for £164 million last year. Still, WAE relies on its extensive experience from the high-performance segment and is primarily known for working towards Formula 1 race cars. The consultancy was, therefore, naturally exclusive.

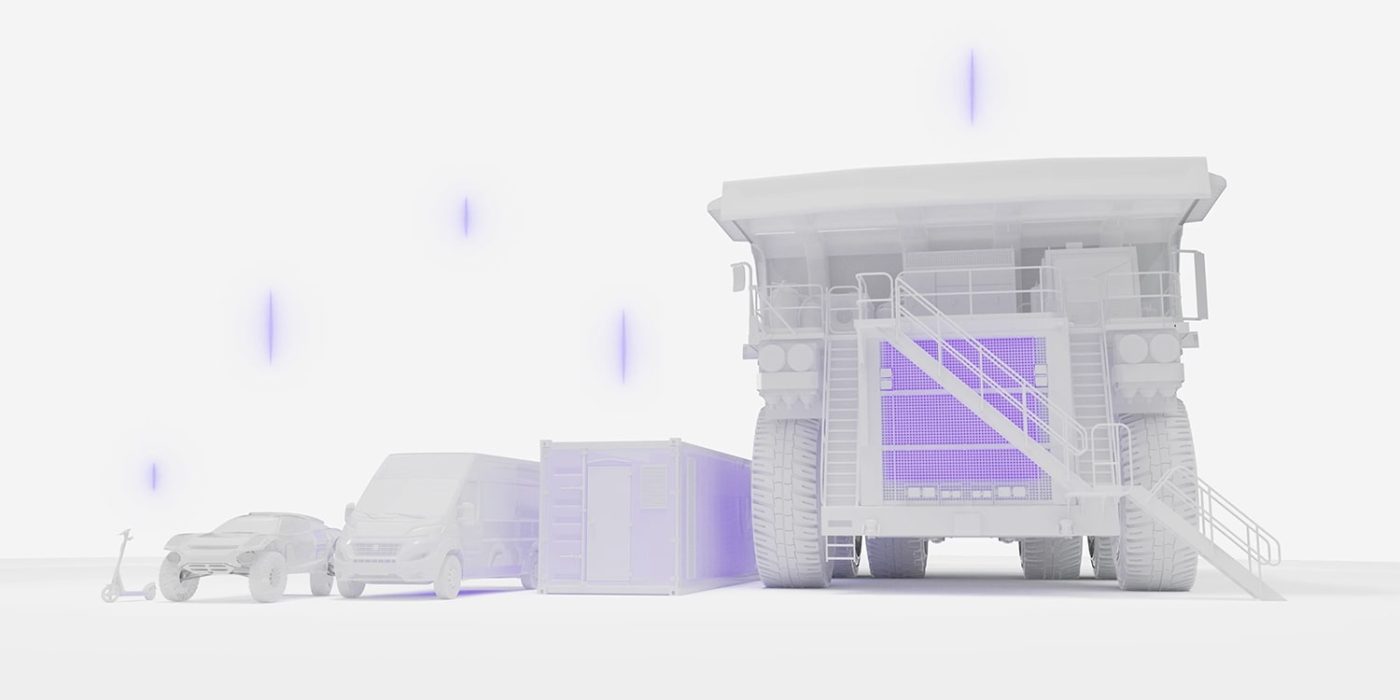

In this week’s call, however, engineer Timothy Engstrom and marketer Joe Jones stressed their roots in electrification and a portfolio including anything from e-scooters over road vehicles to specialist mining machinery (via Fortescue). That is a vast stretch for a company which also claims to offer bespoke services.

It is also the tightrope that Elysia, the new battery intelligence software, will have to walk. WAE says the new suite of BMS service will “unlock significant improvements in the range, life, safety, power, and rapid charging times of any electric vehicle battery”. Elysia is also the company’s first product suite targeted at mass-market uptake.

Hence the mentioning of “any” EV battery. WAE claims that part one of Elyisa, Elysia Embedded, can be applied to any hardware. It is a suite of battery management algorithms that may help OEMs tap the potential of existing systems.

The company’s AI includes six core algorithms that apply to common factors of battery management like the State-of-Charge, State of health, fast charge behaviour, state of power, always-on balancing, and fault prognosis.

While these factors are unsurprising, WAE says, Elysia would apply a more profound analysis to understand the intricacies of the SoC or fast charging. Here, WAE claimed that real-world tests delivered up to a 30% increase in battery life and a 10% increase in battery range whilst significantly reducing fast charge times and increasing peak power output – just by a change in how the battery was managed.

So how do they do that, or how does Elysia differ from other BMS?

We put this question directly to Engstrom and Jones. The short answer: “Elysia understands the cell from the inside out.” This means that WAE is taking the chemistry and electric mechanics on the cell level into account. This, so the company, enables them to tune and calibrate the algorithms more individually.

There was a “colinearity in AI-heavy approach,” Jones explained, “resulting in the fusion between AI data and electrochemical science, separating the signal from the noise”. In press speak, Elysia is built upon a “unique combination of AI and data science, fused with electrochemical modelling expertise, whilst grounded in unrivalled real-world battery engineering and development experience”.

His colleague Engstrom tried to give more hands-on examples. While a standard BMS treats the battery as a “black box,” WAE appears to be taking a more dynamic approach. “An EV having been on the road for four years should charge differently than one fresh out of the dealership,” Engstrom said.

And, where conventional battery management systems traditionally used data from lab testing and limits specified by cell suppliers to build software that controls how the battery is used, WAE says that Elysia gives OEMs more control and insight.

Battery management rooted in real-life

This real-life approach appeared as one of the convincing arguments for Elyisa. The engineers started the call by stating that today’s batteries were heavily overengineered and underused simultaneously. Therefore, by optimising the use of the battery, Elysia wants to help OEMs reduce oversizing and over-engineering, enabling batteries to be smaller, lighter, more cost-effective and more sustainable.

Jones added this was a “bottom-up approach to analytics, fundamentally grounded in the science and physics-informed models of the cell”. This also made them less reliant on building a big data heap since AI alone can’t save batteries, so Jones.

At the same time, according to Jones, Elysia does rely on predictive algorithms and takes a model-based approach as well, especially for the life-cycle analysis, which is more predictive than reactive. This is where the second part of Elysia comes in, Elysia Cloud.

Here, targeted telematics helps WAE to create a digital twin not of the battery but of each cell. “We are absolutely using fleet data to inform our analytics,” stressed Jones. His colleague Engstrom added that they were looking at the cell as a system to gain degradation insights, further diagnostics and prognostics, and performance simulations, for example, in mining trucks.

Taken together, the data is for clients to receive bespoke BMS calibration over the air for WAE to manage and optimise performance throughout the entire battery life.

As a business model, using the Elysia cloud will incur a monthly subscription fee for every connected battery. WAE targets OEMs and fleet customers, incl. bus operators and stationery energy providers. Jones added they were already working with clients on this but did not disclose any names.

As for Elysia Embedded, WAE said they were primarily speaking to automotive and e-scooter manufacturers and also run their own mining trucks via the company’s owner Fortescue. Applying the Elysia BMS to an existing battery works as a license model.

The Elysia battery management suite is the first mass-market offering by WAE and is now available upon request.

Info via press call and email.

1 Comment