CALB announces battery cell with improved density

The Chinese battery manufacturer CALB has presented a new battery technology that is said to offer a significant increase in performance compared to conventional cylindrical cells. This not only involves improved cell chemistry but also a new type of construction.

According to a CALB presentation at the China EV 100 Forum, the new battery type is to use both innovations in cell chemistry, but above all stands out from other round cells due to structural innovation. The technology, which the company calls ‘U-structure’, differs noticeably from the familiar round cell structure.

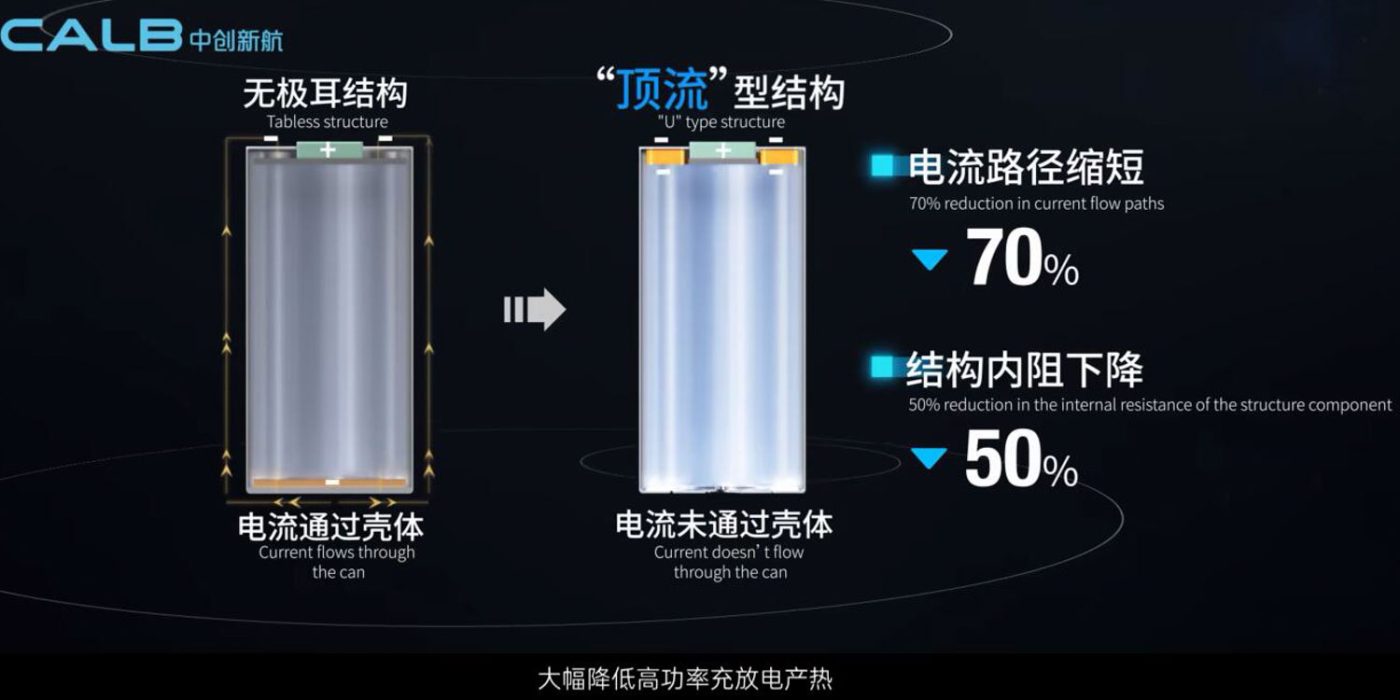

Until now, round cells for electric cars, similar to household batteries, had positive and negative poles at opposite ends of the cell housing. With the ‘U-structure’, CALB installs both the plus and the minus pole on one side of the housing. As usual, the positive pole is in the middle and slightly elevated, and the negative pole is on the outside. For integration into a battery module or pack, this means that this round cell is treated more or less like a prismatic cell with both poles on one side of the housing.

CALB does not go into detail about the structure inside the cell with the ‘U-structure’. However, since with the new design no more currents flow through the cell envelope, these “flow paths” for the currents are said to have been reduced by 70 per cent. This, in turn, has the effect of reducing the internal resistance of the cell by 50 per cent, CALB says.

A lower internal resistance also means that the cell heats up less – an important factor in fast charging, for example. CALB states that the new round cell can be charged with up to 6C – the portal “CN EV Post” assumes a full charge in ten minutes.

The charging rate of 6C should apply to the NMC variant of the ‘U-structure’ cell. According to CALB, this should have an energy density of 300 Wh/kg. There will also be an L(M)FP version, i.e. a pure LFP cell chemistry or an LMFP chemistry with additional manganese. Here, up to 200 Wh/kg are specified for the energy density.

While the 300 Wh/kg and above all the charging rate of 6C should be interesting in high-end vehicles, the ‘U-structure’ is said to offer another advantage, which is likely to come into play above all in low-cost vehicles: CALB Vice President Xie Qiu is reported to have stated at the China EV 100 Forum that compared to tabless round cells (such as Tesla’s 4680 cells), the number of welding machines in the production line of this battery is about 70 per cent less.

“We have made a disruptive innovation to the structure of the cylindrical battery by introducing the ‘U’ type structure,” Xie Qiu is quoted as saying. While the tabless structure solves some of the current path problems, treating the cell shell as a conductive component results in a relatively long path for current flow, he said. The newly developed ‘U-structure’ is supposed to do this much better. However, it is not known when CALB plans to go into series production with this new type of cell.

0 Comments