Farasis Energy announces battery upgrade

The Chinese battery manufacturer Farasis Energy has optimised the design of its battery modules to prevent thermal runaway in the event of damage to its latest generation of cells (Generation 4). Industrial production of the optimised modules is scheduled to start in 2025.

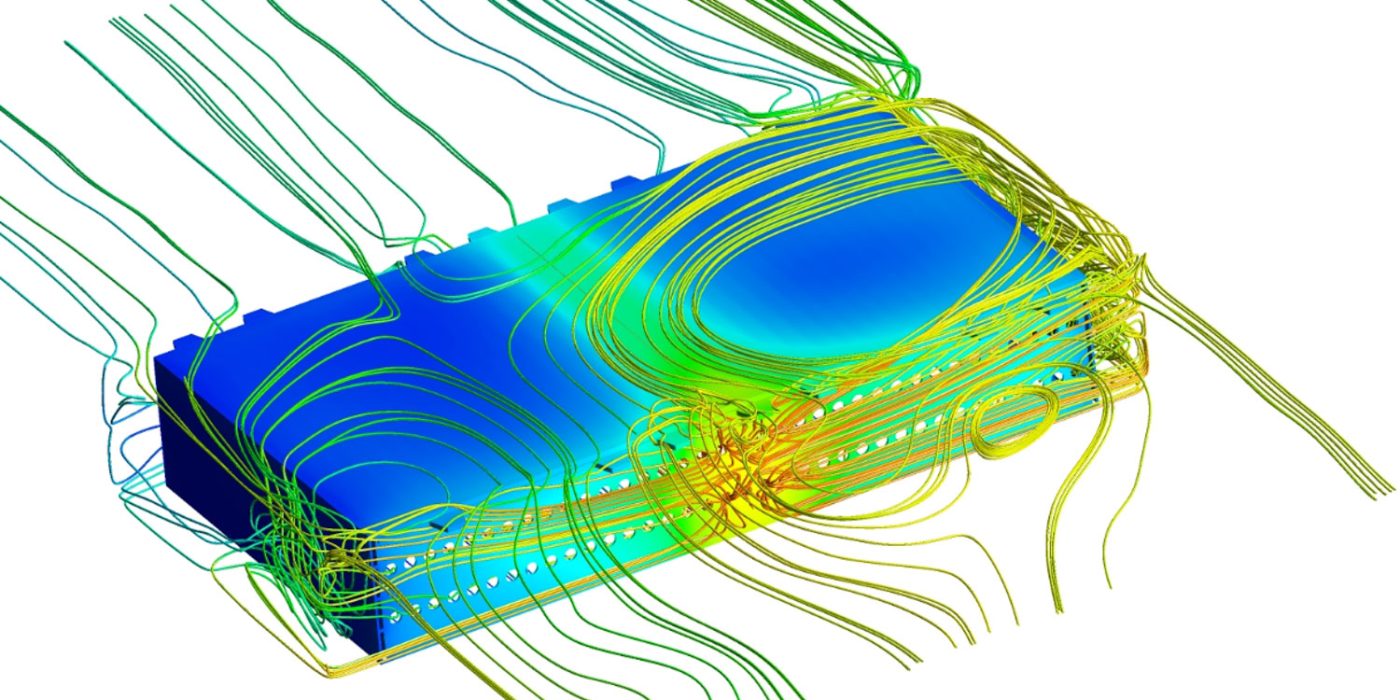

Stefan Bergold, Farasis General Manager Europe, had previously confirmed that Farasis had developed a solution that limits thermal runaway to a single cell and prevents it from spreading to neighbouring cells and later to the entire battery pack. This had been proven by Farasis – “in simulations, demonstrations, real battery modules, real battery packs and also in real electric vehicles”, Bergold said at the time.

As the company now announces, this is exactly what has now been tested and confirmed by independent laboratories at module and pack level. Importantly, Farasis has succeeded with a pouch cell whose outer layer consists only of the eponymous foil pouch. Until now, pouch cells were considered inferior to other battery formats with a hard casing (i.e. mainly prismatic cells and round cells) in this respect. “But stopping the reaction in pouch cells even with a small number of cells, and especially when using nickel-containing cell chemistries, as Farasis has now achieved, is a real novelty and a breakthrough in battery safety,” Bergold now says, according to the release.

Thermal runaway occurs when lithium-ion cells exceed a certain temperature or are damaged. This leads to the formation of a considerable amount of gas with hot particles as well as heat development with temperatures of up to 1000°C and more. On the one hand, these extreme temperatures can directly cause overheating in neighbouring cells, on the other hand, the hot gases with 800 to 1,300 degrees can heat up surrounding cells beyond safe levels. This usually results in a cascade reaction at the module and pack level, known as thermal propagation.

Farasis wants to start industrial production of these modules in 2025, and the first customer enquiries are already being processed, according to the company. However, there will already be measures before then to at least contain thermal propagation – also at other cell manufacturers. The background to this is the increasingly stringent global legislation: in China, manufacturers of electric vehicles will be forced as early as 1 January 2021 (GB 38031-2020) to build their vehicles in such a way that the battery can withstand at least five minutes in the event of a thermal runaway, which should give the occupants time to leave the damaged vehicle. Via ECE R100 Rev3, these requirements will also apply in Europe from 1 September 2023. “In future regulatory updates, these 5 minutes will most likely extend to an unlimited time frame,” Farasis writes.

“Using modern development methods like virtual prototyping and quick testing methods, Farasis has now developed a design that’s able to stop this reaction at a defined number of cells for its most advanced cell chemistry – Generation 4 – with nickel-rich high-energy cells (NMC 811 and even higher nickel content),” says Keith Kepler, CTO and co-founder of Farasis. “This was achieved with pouch cells and has been proven by tests on independent institutes and has been confirmed on module and pack level.”

0 Comments