Schaeffler delivers first in-wheel electric drive for light commercial vehicles

The German automotive supplier Schaeffler is now supplying its first customers with its in-wheel electric drive. Schaeffler will start series production of its electric wheel hub motors for three customers manufacturing compact municipal vehicles in the coming months.

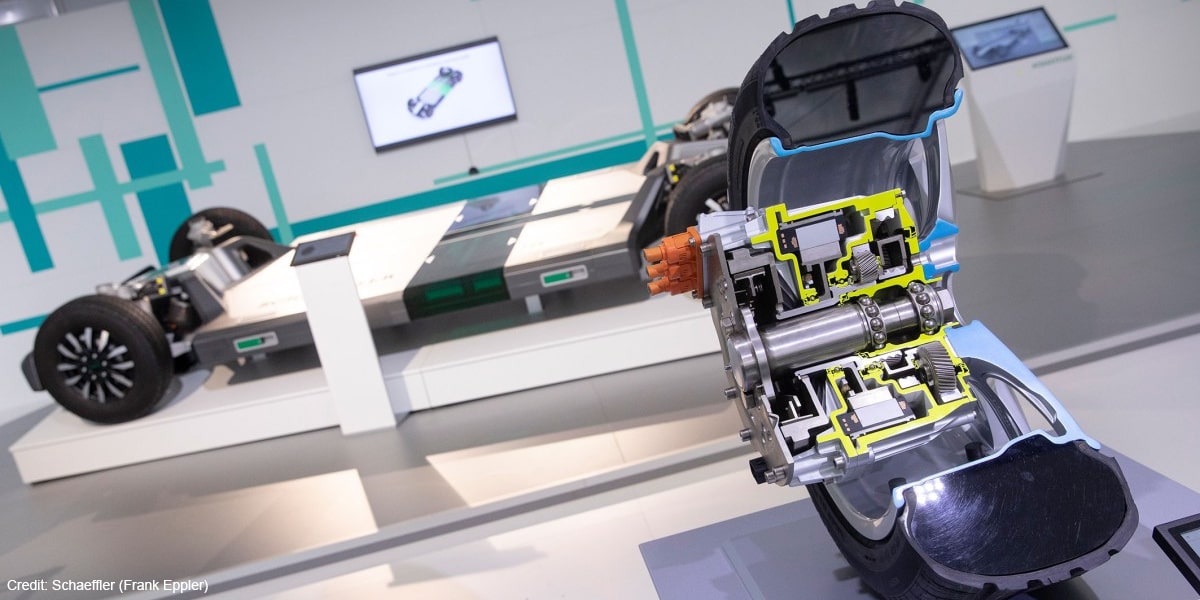

All the necessary drive components are installed directly in the wheel rim. That saves space and, according to Schaeffler, makes the vehicles more agile and easier to manoeuvre in urban traffic. Since the drive unit is no longer located in the centre of the vehicle, installation space freed up that can be used for additional batteries or further storage.

The drive unit, consisting of an electric motor (stator and rotor), a gearbox and a mechanical friction brake, can be integrated into a 14-inch (or larger) rim. The inverter still has to be placed in the vehicle itself, but it does not necessarily have to be in the drive axle and can be positioned flexibly. One inverter can control up to two wheel hub motors. Depending on the connection, the motors have a nominal output of between 7 and 26 kW and a peak output of up to 60 kW. Schaeffler is currently developing drive systems for 48 to 400 volts; higher voltages are also possible in the future, according to the supplier.

One of the vehicles, a multifunction vehicle with wheel hub drive, will come from Jungo. As part of the cooperation, Jungo and Schaeffler say they have adapted the drive for specific everyday requirements of commercial street sweeping. “The electric in-wheel motors and braking technology eliminates the need for oil changes and greatly enhances our vehicles’ performance in terms of efficiency, power-to-weight ratio, safety, handling, and braking reliability,” says Nicolas Jungo, Jungo’s founder and CEO.

Schaeffler is currently focusing on wheel hub motors for mobile work machines primarily used in inner cities. In such vehicles, the disadvantages of wheel hub motors are negligible. The wheel hub drive can make handling more difficult at higher speeds and/or dynamic driving but refuse collection vehicles, snow ploughs, or light vans tend to travel at lower speeds in the city.

With the new drive technology, the company says it is tapping into a new and steadily growing market and intends to equip more and more work vehicles for cities and municipalities, in factory and logistics yards, at ports, in large parking lots and airports with the wheel hub drive in the future. As these vehicles have a fixed route schedule, they are particularly suitable for electric drives with fixed ranges and plannable charging times. Schaeffler says vehicle operators of the vehicles will also benefit from the fact that the wheel hub motors have long-life, low-maintenance wheel bearings and gearboxes, meaning less maintenance and lower operating costs.

0 Comments