German project team tests fuel cell range extender as retrofit solution

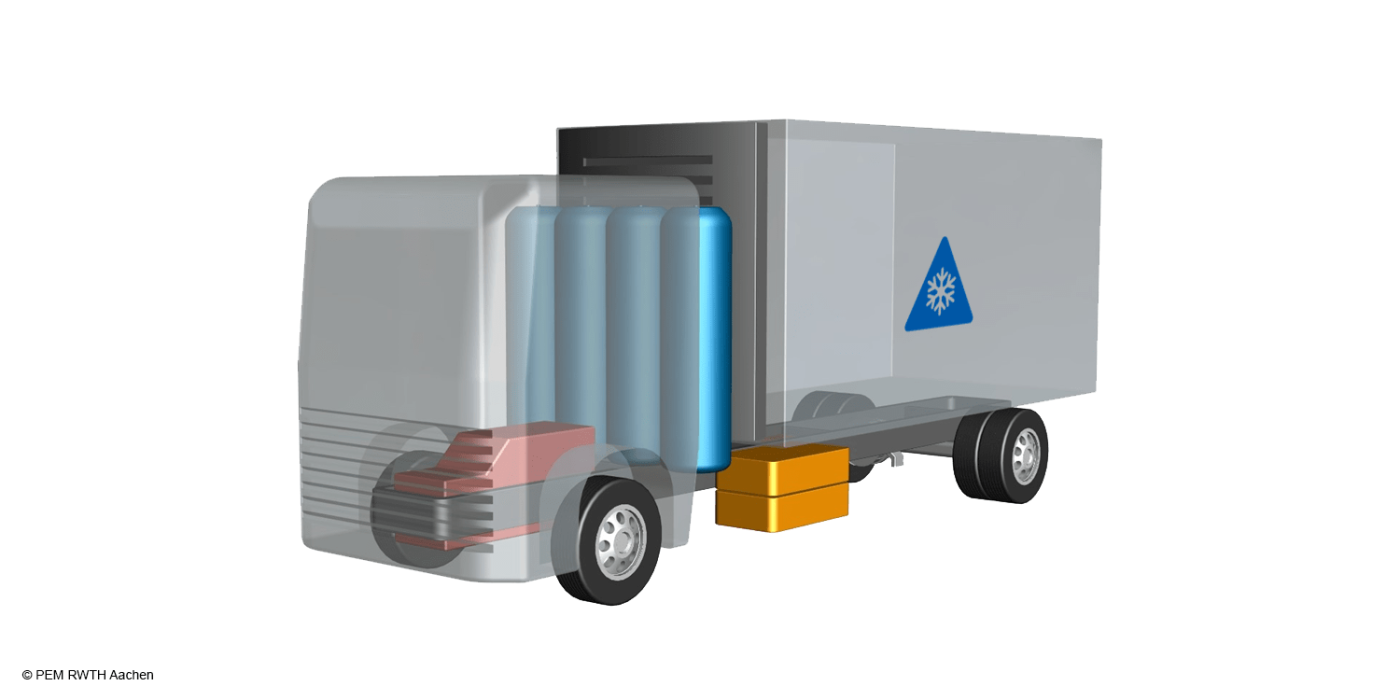

A German consortium led by Orten Fahrzeugbau is developing a fuel cell-based conversion kit in the ‘H2Kit’ project, which is intended to turn commercial vehicles with energy-intensive auxiliary consumers, such as refrigerated trucks, into more efficient electric vehicles.

In the two-year project, the partners want to achieve a lower battery weight and more flexible regulation of the power supply by using a fuel cell range extender. The federally funded project has a total volume of around three million euros and will run until the end of November 2024. In addition to conversion specialist Orten, the Production Engineering of E-Mobility Components (PEM) chair at RWTH Aachen University and AE Driven Solutions GmbH are also involved. Meyer Quick Service Logistics GmbH & CO. KG is also on board.

The project partners agree that in order to meet the climate targets, the conversion and retrofitting of existing vehicles is necessary in addition to the development of new vehicles. “However, when implementing alternative powertrain concepts, transferability to future series production is rarely taken into account,” the PEM Chair of RWTH Aachen University wrote in the press release. The integration of innovations for peripheral components is also not always sufficiently considered. Hence the idea of developing a modular conversion kit from a range extender system that can be used by all vehicle manufacturers and is economically realistic.

In order to achieve this, the kit is to be tested in a truck prototype for its functionality and integrability, the PEM informs. Finally, the research partners want to make their results and experiences available to all interested parties.

“Vehicle-specific design and production of electric powertrains has not yet been possible at competitive costs,” affirms PEM director Professor Achim Kampker. Special applications such as refrigerated trucks require maximising battery capacity due to their high and changing energy demand, which in turn leads to a disproportionately high vehicle mass and a low payload. “Logistics companies, however, need the lowest possible vehicle weight to maximize transportable payload and keep fuel costs low,” says Kampker, who also helped invest the Streetscooter electric transporter.

0 Comments